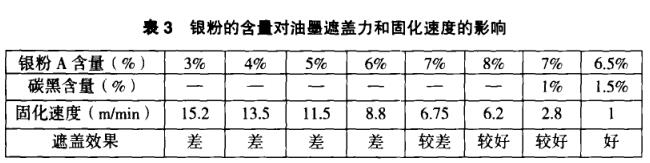

Effect of silver powder on ink curing speed and hiding power

Fix the content of photoinitiator at 5%, change the content of silver powder A to prepare UV screen printing masking ink, and test the curing speed of the prepared ink

and hiding power. It was found in the experiment that when the content of silver powder A is 8%. The transmittance of the ink is 0%, but under the light source of the transmission densitometer, the hiding effect is still relatively poor, so it is decided to add some carbon black to improve the covering power of the ink.

The higher the content of silver powder, the better the hiding power of the ink. In addition to the silver powder, an appropriate amount of carbon black can be added to the ink to better improve the hiding power of the ink. In this experiment, .65% silver powder and 1.5% silver powder were used. Carbon black is used together to prepare UV screen printing covering ink, which can make the ink covering effect more satisfactory. But at the same time, it can also be seen that the higher the content of silver powder, the lower the curing speed of the ink. This also shows that the greater the amount of pigment used, the more ultraviolet light will be absorbed, thereby increasing the competitiveness with the photoinitiator, thus reducing the curing speed of the ink.

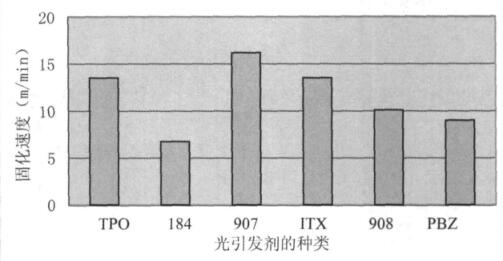

The effect of the type of photoinitiator on the curing speed of ink

Fix the content of silver powder and photoinitiator in the ink to 5%, use silver powder A, change the type of photoinitiator, and prepare UV screen printing masking ink under the condition that other components of the ink remain unchanged, and test the curing speed of the prepared ink ,As shown in Figure 6. It can be seen from the figure that the curing speed of the ink formulated with photoinitiator 907 is faster. By comparing the spectral absorption curve of photoinitiator 907 ( FIG. 7 ) with the spectral absorption curve of silver powder A ( FIG. 1 ), it can be seen that the absorption peak of the spectral absorption curve of photoinitiator 907 is just within the spectral window of silver powder A. This also shows that the relationship between the absorption spectrum of the initiator and the absorption spectrum of the silver powder has a great influence on the curing speed of the ink.

The effect of the content of photoinitiator on the curing speed of ink was prepared by using 65% silver powder and 1.5% carbon black to prepare UV screen printing masking ink, fixing other components of the ink, changing the content of photoinitiator 907 to prepare ink, and testing the ink. Curing speed, the test results are shown in Figure 7. It can be seen from Figure 7 that when the content of the photoinitiator is low, the curing speed increases with the increase of the content of the photoinitiator. When the content of the photoinitiator exceeds a certain value, the curing speed begins to decrease when the content of the photoinitiator is increased. . This is because when the concentration of the photoinitiator is too high, the free radicals produced will be excessive, and the excessive free radicals will increase the chance of free radicals colliding with each other, and the free radicals that actually initiate the crosslinking reaction between the monomer and the polymer will decrease, so Curing speed is reduced. Therefore, the content of photoinitiator should be appropriate and not too high. The best content of photoinitiator 907 in this experiment is 10%.

Conclusion

The type of photoinitiator and silver powder has a great influence on the curing speed of UV ink. To improve the curing speed of UV ink, the photoinitiator should match the absorption of ultraviolet light by the pigment, that is, the absorption peak of the photoinitiator should be as high as possible. within the spectral window of the pigment.

The content of photoinitiator also has a great influence on the curing speed of UV ink. Increasing the content of photoinitiator can increase the curing speed of UV ink, but too high content of photoinitiator will reduce the curing speed of UV ink.

The type and content of silver powder have a direct impact on the hiding power of the ink. The higher the hiding power is, if a small amount of carbon black is added in combination with silver powder, the smaller the diameter of the silver powder will be, and the higher the hiding power will be; the higher the content of silver powder, the The hiding power of the ink is significantly improved

This article is selected from the research results of two scholars, Huang Beiqing and Wang Peimin, in the article "Selection of Photoinitiator for UV Screen Printing Covering Ink and Research on Covering Power" .