Calcium carbonate (CaCO3) is an important and widely used inorganic salt, which is usually divided into heavy calcium carbonate and light calcium carbonate according to different processing methods. Heavy calcium carbonate, also known as ground calcium carbonate, referred to as heavy calcium, is made from natural calcite, limestone, dolomite, chalk, shells, etc. through physical processing; light calcium carbonate is also called precipitated calcium carbonate, referred to as light calcium , is prepared by chemical processing.

At present, the fillers used in powder coatings are mainly barium sulfate, including precipitated barium sulfate and barite powder (ultrafine barium sulfate). After the European Union and the United States list barium in barium sulfate as a heavy metal, the use of barium sulfate in some export products The use is limited, and the price of barium sulfate is higher than that of calcium carbonate. Calcium carbonate is a white filler that is cheap and does not contain heavy metal elements. With the progress of production technology, calcium carbonate is showing a trend towards functionalization and ultrafineness. The trend, its performance has been able to meet the requirements of powder coatings, and the cost can be reduced when used in powder coatings.

Compared with the ordinary heavy calcium carbonate produced by the traditional process and the light calcium carbonate produced by the chemical precipitation method, the deep-processed product of wet grinding ultra-fine heavy calcium carbonate has finer fineness, larger specific surface area, chemical A series of advantages such as higher stability. In this experiment, dry and wet grinding superfine heavy calcium carbonate and light nano calcium carbonate are used in powder coatings, and their properties are compared.

1. Heavy calcium production process

The production methods of heavy calcium carbonate mainly include dry method and wet method. The dry method generally produces heavy calcium below 2500 mesh. It is technically feasible to produce ultrafine heavy calcium above 2500 mesh, but the energy consumption is high. And the cost is high, it is not economically feasible. The production of ultra-fine ground calcium carbonate with a mesh size of 2500 or more mainly adopts wet grinding, while dry grinding is used as the pre-process of wet grinding.

1.1 Dry process

Dry production of heavy calcium is currently the most common method in CHINA, and the technology is relatively mature. Products of various particle sizes can be obtained by using a processing device system composed of general grinding and grading equipment. The main equipment used are Raymond mill, ring roller mill, ball mill, high pressure roller mill, vertical stirring mill, jet mill, etc.; the classification equipment mainly adopts impeller ultrafine classifier. The dry production process has the characteristics of less investment in equipment, mature technology, simple process, low energy consumption, and high output per machine. The conventional dry production process for heavy calcium is shown in Figure 1.

1.2 Wet process

As the processing of heavy calcium is becoming more and more micronized, the traditional dry production process cannot meet the requirements in terms of equipment itself and economic benefits, so the wet grinding process has emerged as the times require. The biggest difference between wet grinding and dry grinding is the difference in the dispersion medium. The dry grinding uses air as the dispersion medium, while the wet grinding uses water as the dispersion medium, together with grinding aids, so that the dispersibility of the particles is better. Higher grinding efficiency and finer particle size. The general wet grinding process is shown in Figure 2. After the raw ore is washed, it is crushed to about 400 mesh in two stages. After dry grinding and grading, it is prepared into a slurry with a certain concentration. Grinding aids are added and fed into a vertical Grinder. Zirconia beads are used as the grinding medium, and the fineness of the output is controlled by adjusting the parameters of the Grinder. The material is discharged in the form of slurry after being ground, and collected and bagged after drying and dust removal.

2. Characteristics of wet superfine heavy calcium

Since the production process and grinding environment of wet grinding heavy calcium are completely different from those of dry grinding heavy calcium and light calcium, there are also obvious differences in the physical properties of the products.

2.1 Comparison of characteristics of wet and dry heavy calcium

(1) Granularity. The ultrafine heavy calcium produced by wet grinding has a fine particle size, and mainly produces products with a particle size of 3000 mesh or more, and the content of particles with a particle size of less than 2 μm can generally reach 90%.

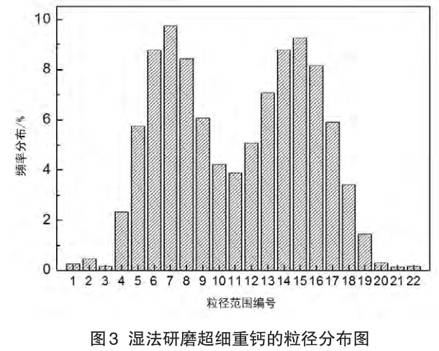

(2) Particle size distribution. The particle size distribution of the heavy calcium produced by the wet method is narrow, showing a unimodal or bimodal distribution; while the particle size distribution of the heavy calcium produced by the dry method is wide, showing a bimodal or multimodal distribution.

(3) Particle shape. Due to the difference in the grinding environment and the way the particles are subjected to force during grinding, the particles of the wet-ground heavy calcium product generally appear spherical or quasi-spherical, while the dry-process products are mostly amorphous with obvious edges and corners.

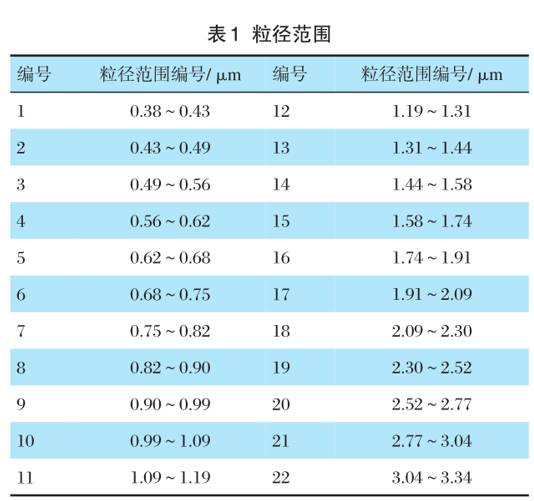

Table 1 and Figure 3 are respectively the particle size range and particle size distribution diagram of wet grinding ultrafine heavy calcium. It can be seen from Figure 3 that the particle size distribution of wet-ground ultrafine heavy calcium presents a bimodal distribution, with peaks appearing at 0.75-0.82 μm and 1.58-1.74 μm respectively, and most of the heavy calcium particle sizes are below 2 μm , belonging to micron-scale materials.

2.2 Comparison of characteristics of wet superfine heavy calcium and light calcium

(1) Light calcium is produced by chemical precipitation method, the particle size is small, and the particles are generally spindle-shaped or chain-shaped. The oil absorption value is higher than that of heavy calcium. Even the surface-treated light calcium has a higher oil absorption value than ordinary wet heavy calcium. This leads to an increase in the amount of additives when light calcium is used as a filler.

(2) The application field of wet-process heavy calcium is wider than that of light calcium. In some fields (such as plastics), since the fluidity of wet-process ultra-fine heavy calcium is better than that of light calcium, its addition amount is larger than that of light calcium.

(3)湿法重钙由于采用的是物理方法加工生产的碳酸钙,在产品生产的过程中只加入了水,没有任何杂质和化学物质的影响,产品的化学稳定性较高;轻质碳酸钙采用化学合成的方法生产,在碳化反应的过程中容易产生过饱和反应,容易造成产品表面的游离酸碱值不稳定,同时产品中容易带入煤灰等杂质。

3.湿法超细重钙在粉末涂料中的应用

在粉末涂料的生产中,出于成本的考虑,通常会在配方设计中添加一些填料以降低成本。粉末涂料中常用的填料为硫酸钡,但天然硫酸钡矿床(重晶石)普遍含有一定量的重金属元素,在生产过程中很难将其分离出来,且钡元素本身已经被欧盟和美国定义为重金属元素,这些因素都影响了硫酸钡在粉末涂料中的应用。而重质碳酸钙是由天然方解石、白云石等矿石直接加工制得,不含重金属元素,且碳酸钙原矿资源丰富,价格低廉。因此,已被广泛应用于粉末涂料中。

3.1 碳酸钙在粉末涂料中的作用

碳酸钙在粉末涂料中起骨架作用,增加漆膜厚度,提高涂层的耐磨性和耐久性。可降低涂料的成本,提高粉末涂料的上粉率和喷涂面积,另外它不含重金属,是不含重金属类粉末涂料的优先选择填料。

3.2 实验部分

3.2.1 原材料及配方

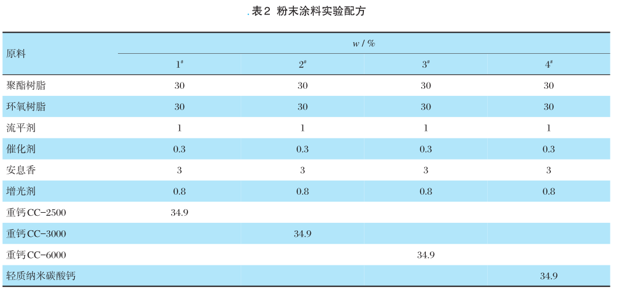

为充分验证不同细度湿法重钙在粉末涂料中的应用性能,我们选择干/湿法重钙、轻质碳酸钙等填料与其进行对比性实验,原料及实验配方见表2。

3.2.2不同填料的物理性能测试结果

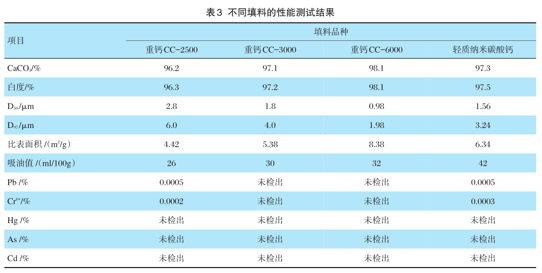

按HG/T3249.2-2008 《涂料工业用重质碳酸钙》标准测试了 CC-2500、CC-3000、CC-6000,按HG/T2226-2010 《普通工业沉淀碳酸钙》标准测试了轻质纳米碳酸钙,测试结果如表3所示。其中CC-2500为采用干法研磨生产的 2 500 目产品;CC-3000 和 CC-6000为采用湿法研磨生产的产品;轻质纳米碳酸钙为国内某大型轻钙生产企业的产品。

From the results in Table 3, it can be seen that the fineness of CC-6000 product is the finest, and its specific surface area is also the largest. Since the finer powder is easier to exert the effect of each particle, it has a higher Light transmittance and mechanical properties, because CC-6000 is wet-ground ultra-fine calcium carbonate, its particle shape is uniform and regular, and it should have higher gloss when applied to powder coatings.

3.2.3 Performance test of different fillers in powder coatings

According to the experimental formula in Table 1, different fillers were added to prepare powder coatings, and the test results are shown in Table 4.

It can be seen from the results in Table 4 that when wet-process calcium carbonate is applied to powder coatings, its gloss tends to rise with the increase of fineness; and light nano-calcium carbonate is not applicable due to its large oil absorption. In high-gloss products; and its impact resistance is not as good as wet calcium carbonate.

4. Conclusion

Wet grinding superfine heavy calcium carbonate can be widely used in coatings, plastics, rubber, ink and other industries due to its small particle size, uniform particle shape and regular particle shape, which is spherical or approximately spherical; when used in powder coatings, wet grinding Grinding ultra-fine heavy calcium carbonate can prepare high-gloss powder coatings. Its overall performance is better than that of light calcium carbonate. In some application fields where heavy metal content is limited, calcium carbonate can be used instead of barium sulfate. It is mainly used in indoor appliances, baby toys, etc. field of painting.