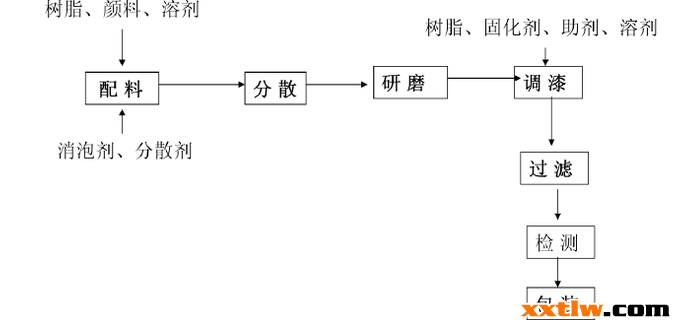

1. Batching Batching should be completed twice. First, the grinding paste is prepared according to a certain ratio of pigment/base material/solvent to make it have a good grinding efficiency; after dispersion and grinding, the remaining components are supplemented according to the color paint formula, and then the dispersion and mixing are carried out. The ingredients strive to be accurately weighed. 2. The influence of dispersion of dispersed pigments in the paint on the performance of the paint First, the color paint first requires uniform color. If the pigment is not uniformly dispersed in the paint, it will cause the paint film to have different shades of color and affect the purpose of decoration. . Second, the pigment is solid, and its specific gravity is generally greater than that of the paint. If it is unevenly mixed and dispersed in the paint, it will precipitate and agglomerate during storage. Third, the color paint is painted into a film, and the film thickness can generally reach less than 20 μm. If the pigment aggregate is too large, it will make the paint film rough and affect the gloss if it is not dispersed to a suitable size. Therefore, the uniform dispersion of the pigment is very important. Dispersion is to mix the prepared pigment and paint to make the pigment wet and disperse initially, and also to prepare for the next grinding. 3. Grinding The grinding process is to tear up the pigment agglomerates and the coagulation of the pigment itself and the air bubbles contained in it under the action of shear force, and to grind the larger powder particles into the specified fineness. Obtain even and fine color paste in which the pigment is dispersed in the paint. Grinding equipment mainly includes sand mill, ball mill, three-roll machine, etc. Different grinding equipment has different grinding process parameters. Grinding viscosity: three-roll machine > ball mill > sand mill Grinding fineness: three-roll machine > sand mill > ball mill Grinding efficiency: sand mill > ball mill > three-roll machine Cleaning difficulty: three-roll machine > ball mill > sand mill 4. Paint mixing is the process of mixing the color paste with the resin solution, solvent, additives and other components required for the paint by mixing equipment to prepare the color paint. The paint mixing equipment can use a container with stirring. 5. Filtration The purpose of the filtration process is to remove unground pigment particles and impurities, paint skin, etc. mixed in the production process. Filtration equipment mainly consists of plate and frame filter, centrifugal filter, bag filter and so on.