【Abstract】A brief introduction to some system formulations and general technical indicators of transparent powder coatings, as well as key points of production process control.

1 Overview

Transparent powder coatings are usually used in special high-end decoration fields. As a very unique variety, powder coating factories invested by foreign groups in CHINA have established production lines for transparent powder coatings. The main raw materials are all produced by foreign companies. In addition, in order to prevent technical leakage, some special additives are specially processed when imported.

2. Transparent powder formulations of various systems

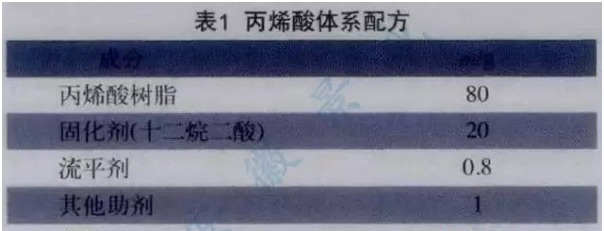

2.1 Acrylic acid system (see Table 1)

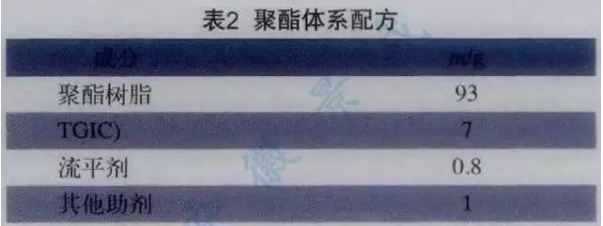

2.2 Polyester system (see Table 2)

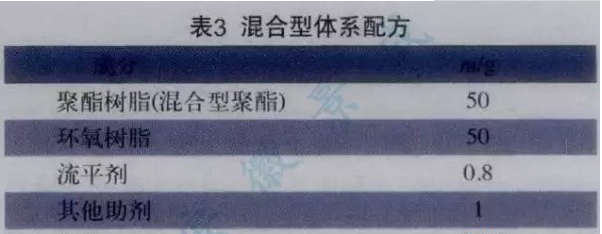

2.3 Hybrid system (see Table 3)

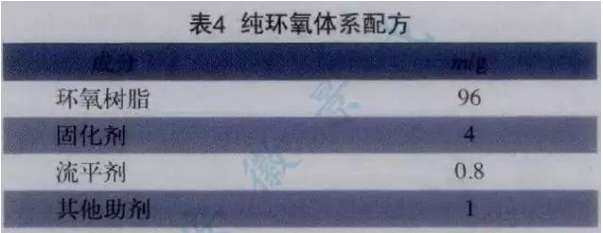

2.4 Pure epoxy system (see Table 4)

2.5 Considerations for ingredient selection

1) The resin not only needs to have good transparency, but also has excellent yellowing resistance.

2) Choose non-adsorbed liquid leveling agent, or special leveling agent for transparent coatings.

3) Choose a curing agent with high purity.

4) To improve durability, a small amount of anti-ultraviolet additives can be added.

5) When crushing, 0.1% alumina can be added appropriately for sieving, and its storage stability can be appropriately improved.

3. General technical indicators of transparent powder coatings

3.1 Powder coating

No mechanical impurities, loose and not agglomerated (visual inspection): powder coating density: (1.15±0.05) g/mL.

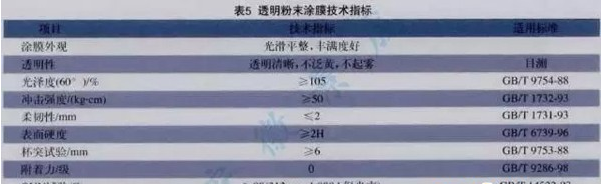

3.2 Coating film (see Table 5 for technical indicators)

4. Process

The production method of transparent powder is similar to other powder coatings, and it needs to go through the following processes: batching→premixing→melt extrusion→tabletting→crushing→sieving→spraying. Due to the poor anti-pollution ability of transparent powder coatings, the process control during the entire production process should be particularly strict, otherwise defects such as shrinkage cavities and mottled colors will easily appear.

4.1 Stability of formula

The quality of raw materials is the basic condition to ensure the quality of transparent powder coating products. Therefore, various technical indicators of raw materials, such as resin gelation time, softening point, and reactive functional group technical indicators, need to be checked regularly to ensure that product quality meets customer requirements. need. To make the formula stable and continuous, it is also necessary to control the quality of the same powder coating product in the same batch or in different batches.

4.2 Production process control

粉末涂料的生产过程是一个物理混合过程,预混合的目的就是把树脂、固化剂、助剂等物料在干态下混合均匀,为熔融挤出创造条件,并获得较好的分散效果。如随意混合一下,会造成配方的不稳定,粉末质量将下降。挤出是粉末涂料生产的核心工序,对粉末涂料质量有决定性的影响,挤出机混炼效果不好,将影响产品光泽,同时流平性也变差,还会出现混炼不匀、局部胶化、形成板面粒子等弊病。粉碎的主要目的就是使粉末涂料的粒径分布适合静电喷涂。

4.3粉末涂料的粒径

适合静电喷涂的透明粉末涂料,其粒径控制在10—40微米较好。透明粉末涂料的粒径是判断粉末涂料质量好坏的一个重要指标,透明粉末涂料产品的流平性、上粉率及稳定性等都与粉末粒径有关,因此,控制粉末涂料粒径是透明粉末涂料质量好坏的关键问题。

4.4粉末涂料流化效果

流动性好的粉末涂料在使用过程中易于流化,显得很蓬松,有流水般的效果。从供粉桶至喷枪,粉末传送轻便,且粉末从喷嘴出来雾化好,没有结团或吐粉现象。

4.5生产过程中的缩孔异常处理

缩孔是指在粉末涂料成膜时表面上山于低表面张力的点引起的特殊缺陷。透明粉末涂料生产中经常会遇到这样的问题。为了减少缩孔的影响,可以采取如下的措施:

*保持整个加工环境的清洁。为避免由于外部环境原因而影响缩孔的产生,要特别注意整个工作环境清洁。

*恰当选取一些润湿剂。一些润湿剂可以有效润湿并且很好地分散引起缩孔的颗粒。

*增加粉末涂料的黏度。

5、结语

综上所述,透明粉末涂料生产过程中,每一个细小的工艺环节对最终产品质量都起着举足轻重的作用。

在选择固化体系时一定要注意,若固化剂的熔点和涂膜的烘烤温度接近,则熔融和交联反应会同时发生最终导致流平效果不是特别好;

选择原材料时,要考虑到树脂和固化剂的反应产物活性,因为这会影响到粉末的贮存稳定性;

仔细筛选具有高透明性的流平剂;

树脂的兼容性较差,要严格控制生产工艺,防止交叉污染的产生;

Be sure to pay attention to the compatibility between the clear coat and the base coat to ensure good interlayer adhesion.