0 Preface

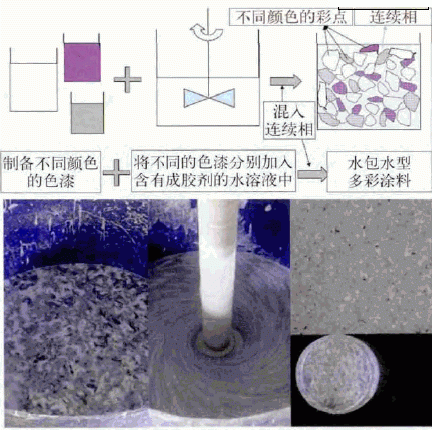

Colorful paint is a new type of decorative paint. Compared with granite marble and real stone paint, it has many advantages such as lifelike simulation, excellent performance, simple construction technology, relatively low cost, and no pollution to the environment. It can replace Granite and other stone materials can reduce the mining of natural stone materials and avoid the danger caused by the shedding of natural stone materials. Colorful coatings can be divided into four categories: oil-in-oil, water-in-oil, oil-in-water, and water-in-water. With the improvement of people's requirements for water-based, the first three types are basically eliminated, and water-in-water multi-color coatings have become a research hotspot. Water-in-water colorful paint is composed of incompatible two-phase components, one of which is the continuous phase of the dispersion medium, and the other is the dispersed phase, and two or more colored particles of different colors, sizes and shapes are uniform Suspended in a dispersion medium containing a stabilizer to form a composite suspension dispersion coating. The film forming process is shown in Figure 1. Among them, the high-viscosity, high-concentration colorful component phase can be suspended in the low-viscosity and low-concentration phase, and after coating, it will be dispersed to obtain a variety of color pattern effects, and it can also have reliefs with unevenness, strong three-dimensional effect, and elegant luster. Shaped appearance texture effect. "Environmentally friendly, elegant, energy-saving" water-in-water multi-color paint is favored by the market for its multi-functionality and high decorativeness, and it is a new type of environmentally friendly coating material with great potential.

In the development of water-in-water multicolor coatings, the stability of color particles (including mechanical stability and storage stability) is one of the main problems. Color particles should not settle, insoluble in water and insoluble in each other during storage, and maintain their independence. In addition, the size of the color particles is not easy to control. This paper develops a water-in-water multi-color coating. The softness and hardness of the color particles of the paint can be adjusted at will, the leveling of the color particles after drying can be adjusted at will, the concave-convex pattern and the flat pattern can be adjusted at will, and the product stability can reach 1~ 2a.

1 Experimental part

1.1 Test raw materials emulsion M-06, emulsion M-02, color particle gel DC30, color particle protective glue, kaolin, titanium dioxide R930, film-forming additive TE, multi-functional additive AMP-95, defoamer, sterilization agent, thickener, propylene glycol, ammonia, water.

1.2 Test formulation The formulation of the multi-color paint should meet the following requirements: stable storage, good comprehensive physical properties of the coating film, raw materials should be as easy as possible, the cost should be as low as possible, and the preparation process should be as simple as possible.

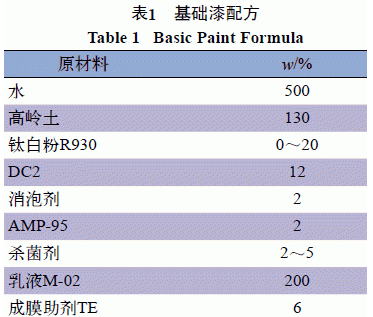

1.2.1 Preparation of base paint Add water, kaolin, titanium dioxide R930, DC2, and defoamer in sequence, stir and disperse at a medium speed for 10 minutes until completely dispersed. Then add the multifunctional additive AMP-95, the viscosity increases, and disperse at a high speed for 20 minutes; then add the fungicide, emulsion M-02, film-forming aid TE, 7% DC30, and water, and disperse at a high speed for 20 minutes. Packaged and ready to use. The formulation of the base paint is shown in Table 1.

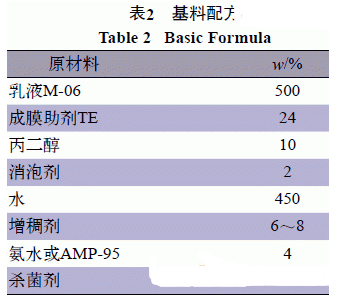

1.2.2 Preparation of base material First mix the thickener and water evenly and adjust the pH value to 8-9 with ammonia water. Then add emulsion M-06, film-forming aid TE, propylene glycol, and defoamer in sequence and stir evenly. Finally, add fungicide to disperse for 20 minutes, and pack for use. The formula of the base material is shown in Table 2.

1.2.3 Preparation of color particles Adjust the base paint color paste into various color base paints, add 7% DC30 medium and stir at a low speed (the speed gradually increases from 200 r/min to 600 r/min) to produce color particles of appropriate size. For storage, add appropriate amount of 0.15% sodium pyrophosphate to thicken. See Table 3 for the formulation of the color grains.

1.2.4 Preparation of colorful paint Dilute the color particle protective glue with water 1:1, then add it to the color particle, stir well, then add the base material, and disperse for 20 minutes. The color paint is dispersed, wrapped by protective glue, and separated from each other to form a stable dispersion, and then the finished product is packaged. The preparation process diagram is shown in Figure 3.

1.3 Performance test

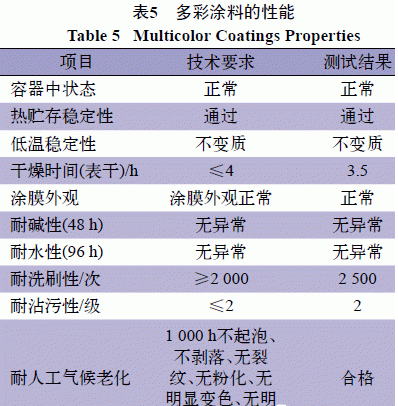

According to HG/T 4343-2012 "Waterborne Colorful Architectural Coatings", the performance test of water-in-water colorful coatings is carried out, and the results are shown in Table 5.

2 Results and discussion

2.1 成膜物质的影响成膜物质是构成涂料形成连续性立体网状结构涂膜的主要物质,是决定涂膜物化性能的关键材料。用于多彩涂料的成膜物质可以是苯丙、纯丙、硅丙、氟硅乳液等,由于大多数乳液中的官能团或乳化剂往往会被其他助剂吸附或发生反应,通常会破坏“卡屋”结构,出现散色、渗色;基础漆中乳液与保护胶发生反应,引起粒子逐渐膨胀,导致造粒批次不均一;连续相中,乳液与保护胶发生反应,形成涂料絮凝或后稠;乳液与保护胶体系兼容稳定性差,加剧涂膜遇水起泡、发白现象且难以恢复,因此,能否选择与保护胶兼容性较好的乳液,对水性多彩涂料的稳定性非常关键。多彩涂料体系中基础漆(分散相)的乳液与成品漆(连续相)的乳液,它们之间的配伍性也重要性无庸赘述,如果选择不正确,体系会出现严重分层或后增稠,导致成品失败。试验选择弹性乳液M-02做基础漆的成膜物质,与成品涂料里的乳液M-06相匹配,生产出来的水性多彩涂料,造粒柔软硬度可随意调节,颗粒分散均匀,贮存稳定性好。

2.2 彩粒保护胶的影响彩粒保护胶的种类和凝胶溶液的浓度对多彩涂料的彩粒稳定性重要性无庸赘述。同时保护胶的用量决定着彩粒干燥后的流平性。为了使一定形状与大小的彩粒在涂料体系中保持长期稳定,达到不粘连、不破碎、不混色,就需要选用与涂料体系相匹配的保护胶。本试验选用高纯度去离子化的硅酸盐类化合物作彩粒保护胶,它不溶解于水但可在水中水合膨胀形成无色透明液体,在水中加量为5%~8%时,可以在24 h内保持流动。在有少量电解质的条件下能迅速形成很强烈的触变性和增稠作用。

2.3 助剂的影响在涂料生产中助剂的用量一般不大,但能赋给涂料以特殊性能,正确地选择助剂,能提高生产效率和产品质量,使造粒良好、贮存稳定、便于施工,涂膜柔韧丰满,还可扩大产品用途、改善涂料的施工性能等。本试验主要选用以下几种:凝胶剂、分散剂、消泡剂、成膜助剂、增稠剂、杀菌剂、pH值调节剂等,这些助剂在水性多彩涂料体系中相容性好。

2.4 Analysis of common problems of multi-color coatings The multi-color coating system is complex, the correct selection of raw materials and reasonable ratio are the key to the preparation of multi-color coatings, and they are also the guarantee of the quality of multi-color coatings. Colorful paints often have some problems in the paint making and storage, transportation and construction, and painting stages, and the occurrence of these problems is closely related to the formulation components of the paint.

In the process of manufacturing and painting colorful paints, in order to ensure product quality, the following issues need to be paid attention to:

(1) During the manufacturing process, the control of the stirring speed.

(2) Color matching. Because it is a marble-like color composed of toning, special attention should be paid to the matching of toning.

(3) The Spray Gun is very critical, and the caliber of the Spray Gun is determined.

(4) The construction repeatability is good. As for the imitation of granite and marble, it is not enough to do a good job in the laboratory model. When large-scale construction is required, the color should be as simple as possible.

3 Conclusion

With the vigorous development of domestic decorative coatings, the demand for high-grade, high-decorative and high-tech environment-friendly decorative coatings will become more urgent. Water-in-water multi-color coatings can provide fancy marble simulation patterns of different sizes and colors according to different material surfaces and customer needs, and can be widely used in the exterior walls of hotels, office buildings, residences, schools, and hospitals , can also be used on the surface of metal and wood, and can also be applied to the surface of ceramics, lamps, furniture, sculptures, handicrafts, etc., so that the decorated surface not only has a lively and generous dynamic, but also has a more elegant and solemn texture. Water-in-water multi-color paint is a novel, potential and environmentally friendly paint that is in line with the future development direction of paint because of its excellent paint matching performance and cost performance. It has a broad market application prospect.