Titanium dioxide is the king of white pigments and one of the important paint pigments. It is favored because of its excellent optical properties and pigment properties. When evaluating the role of titanium dioxide, many insiders and outsiders believe that the per capita consumption of titanium dioxide represents the level of economic development and civilization of a country or region. However, whether it is titanium dioxide produced by the chloride method or the sulfuric acid method (that is, titanium dioxide particles), and whether it is rutile or anatase (used in high-end applications such as coatings, plastics, and chemical fibers), even if the average particle size and deviation are different Relatively satisfactory, without perfect surface treatment (commonly known as coating), can not give full play to its excellent optical properties to make the color bright and colorful, and has good weather resistance, aging resistance and good chemical stability. Therefore, titanium dioxide surface treatment-coating is a very important process.

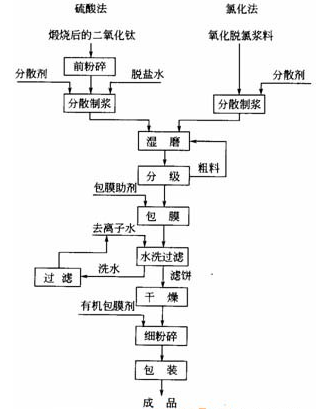

The surface treatment of titanium dioxide, also known as post-treatment, is realized by a complete system. It includes multiple processes such as pre-crushing, dispersing, wet grinding, grading, coating, washing, drying, crushing and packaging. The surface treatment process of titanium dioxide is shown in the figure.