The formula of epoxy resin powder coating is shown in the table below:

Basic formulation of epoxy resin powder coating

raw material name | quality score | parts/100 parts of resin |

Epoxy resin (DER-663U) | 63.6 | 100 |

Modified dicyandiamide (Epon P108) | 3.40 | 5.35 |

Leveling agent (Moda flow Powder) | 0.84 | 1.32 |

Titanium dioxide (R-902) | 31.66 | 49.78 |

Benzoin | 0.50 | 0. 79 |

Production Process

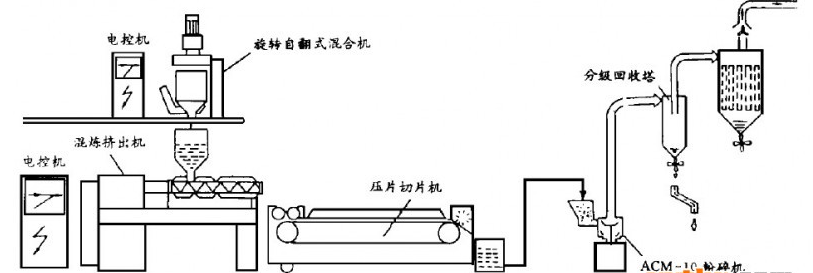

Pre-disperse the leveling agent into part of the resin (accounting for 13%~19% of the total resin in the formula), and then crush the mixed component to a particle size of 3~5 mm. The rest of the resin (accounting for 87%~81% of the total formula resin) is also coarsely crushed to a particle size of 3~5 mm. According to the recipe, pre-mix all the components in a high-speed mixer for 1-5 minutes, and then feed the homogeneous mixture into a single-screw or twin-screw extruder for extrusion. The temperature of the machine cavity is 75~85 ℃, and the temperature of the extrusion head is 95 ℃. The average residence time of materials shall not exceed 60 s. The extrudate is compressed into tablets by a cooling tablet machine, cooled and crushed. It is sent to ACM mill (crusher), crushing and grading are carried out at the same time. The ultrafine powder is then separated with a cyclone separator and the ultrafine powder is collected with a bag filter. The products collected by the cyclone separator pass through the high-frequency vibrating vibrating screen to obtain the required powder coating. Its production flow chart is shown in the figure below.

Epoxy resin powder coating automatic production flow chart