If the rails are like the two legs of a train, then the flaw Detector is the doctor who diagnoses the rails. Due to the rolling of the train and the change of thermal expansion and contraction of the metal, the rail often produces some diseases and even breaks the rail. In winter, the prevention of breakage is the top priority in the safety of the public works system, and the rail weld is the weakest link of the line, and strengthening the flaw detection of this part is the most direct and effective technical measure to reduce the rail breakage and ensure the safety of transportation. Therefore, the flaw Detector should use the combination of ultrasonic rail flaw Detector and manual inspection to strengthen the "physical examination" of the rail, timely and accurately find various rail diseases, and take timely remediation measures according to the damage of the rail. Really learn the lessons of 3 weld breaks, today Xiao specially collected the typical diseases in weld flaw detection, and showed it to you more intuitively in the form of pictures.

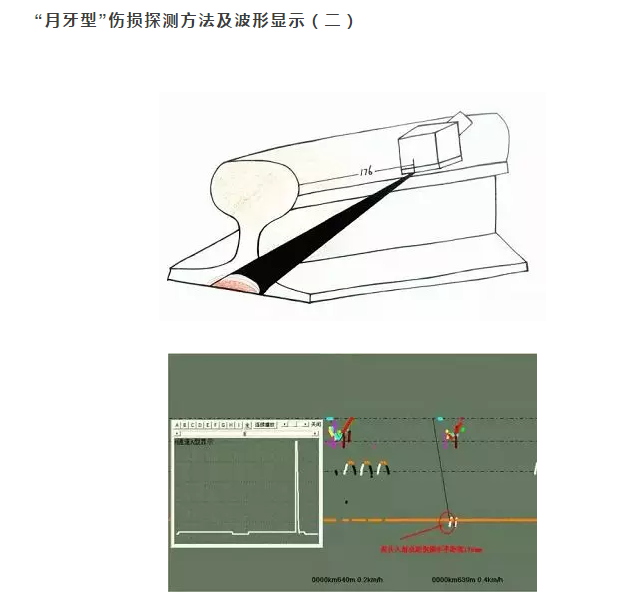

The flaw detection method for the transverse crack at the bottom of the weld rail is a "crescent-shaped" damage (perpendicular to the bottom of the rail, constituting a right-angle reflection between the crack and the bottom surface of the rail): the probe K1 or the rail flaw Detector 37° probe can be used for on-site operation, and the probe incidence point is 176mm (K1 probe) and 132mm (37° probe) from the damage damage 176mm (K1 probe) and 132mm (37° probe) Combined with the on-site rail surface state and coupling, the transverse crack size of the second area of the derail bottom can be detected: 8mm high and 8mm wide.

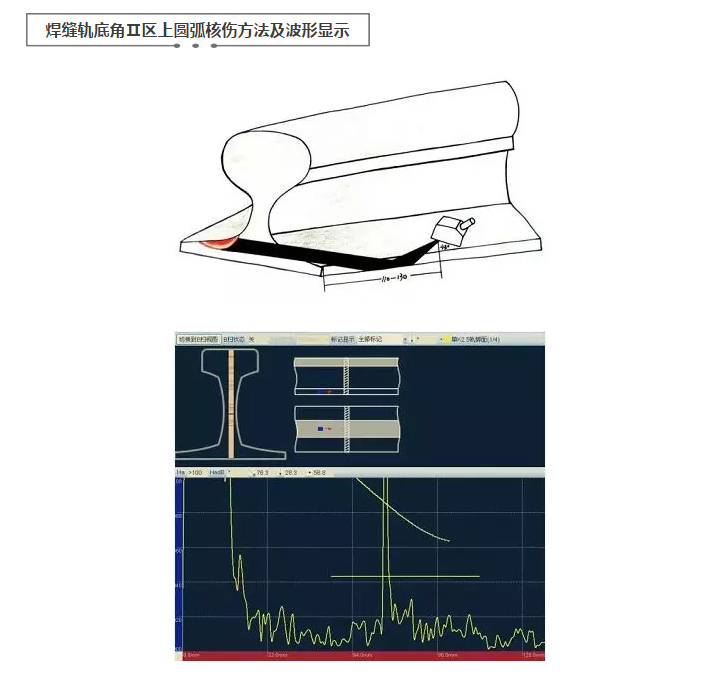

The arc nuclear damage on the bottom angle of the weld rail is the key point of flaw detection, and it is also the difficulty of flaw detection, and the conventional flaw detection method cannot effectively detect this kind of flaw damage. Through on-site exploration and practice, using the (2.5P 8*12)K2.5 probe, at a distance of 110-130mm from the edge of the weld bar in the bottom angle of the rail, the arc damage on the lower angle of the weld can be found by using the secondary wave reflected at the bottom of the rail.

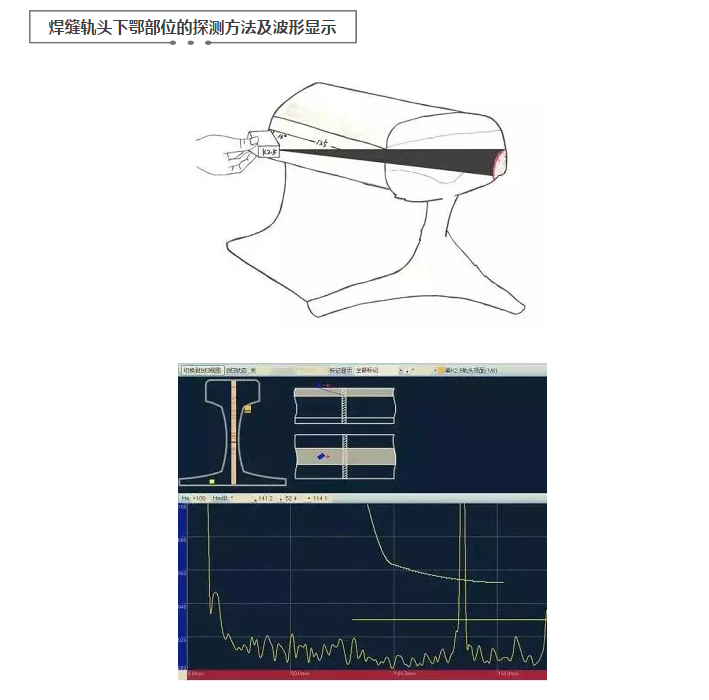

The jaw of the rail head of the thermite weld is damaged due to poor welding process, and the flaw detection of the jaw part of the weld rail head can be used (2.5P 8*12) K2.5 probe to scan the rail jaw defects from the side of the rail, the horizontal distance between the incident point of the probe and the damage is 125mm, and there is a deflection angle of about 13 ° downward, and the horizontal position is marked on the 4 sides of the rail head, and the probe is moved back and forth, and the size of the rail jaw damage can be detected as: width 10mm, height 15mm.

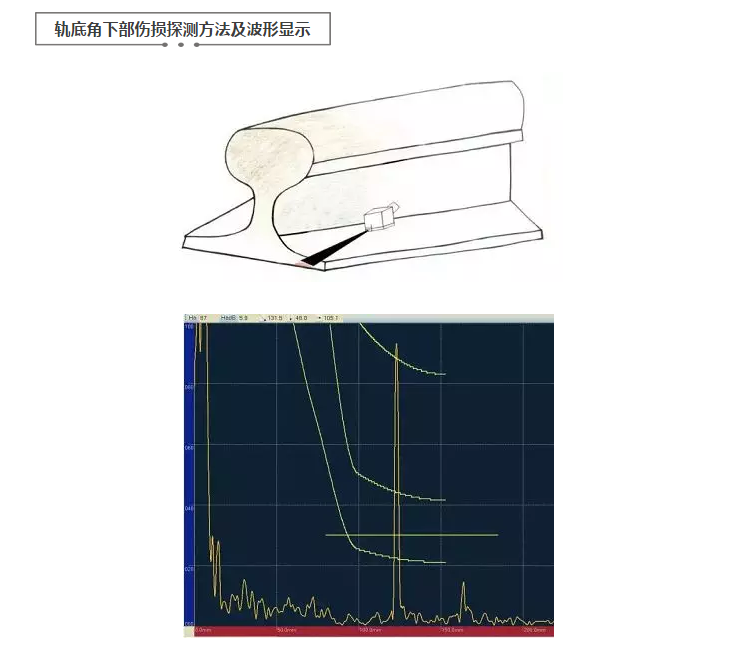

For the transverse crack at the lower part of the bottom corner of the rail, the rail flaw Detector instrument is used to detect the primary wave on the corresponding slope of the rail foot, and the declination, rotation and zigzag shape are scanned along the longitudinal direction of the rail, and the welding damage and fatigue damage of the weld rail foot can be found.

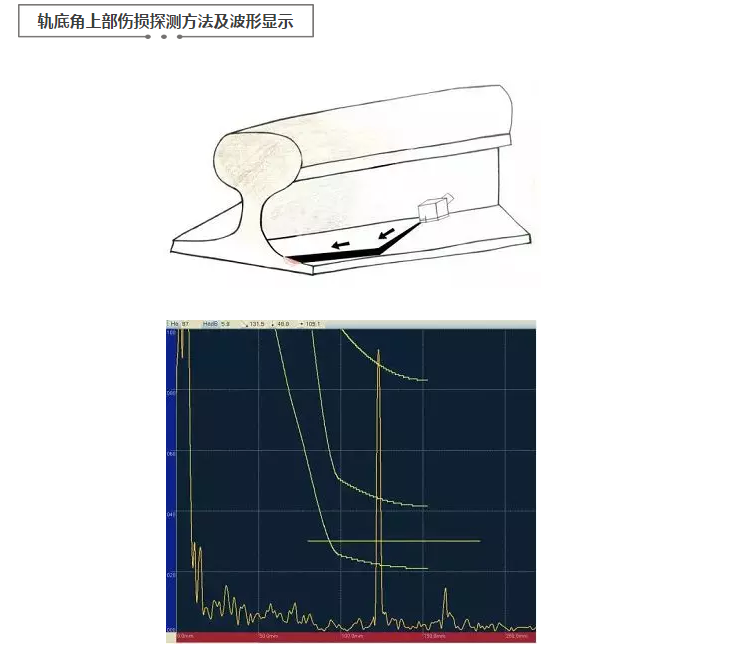

For the transverse cracks in the upper part of the bottom corner of the rail, the rail flaw Detector instrument is used to detect the secondary wave on the corresponding slope of the rail foot, and the deflection angle, rotation and zigzag shape are scanned along the longitudinal direction of the rail, and the welding damage and fatigue damage of the weld rail foot can be found.

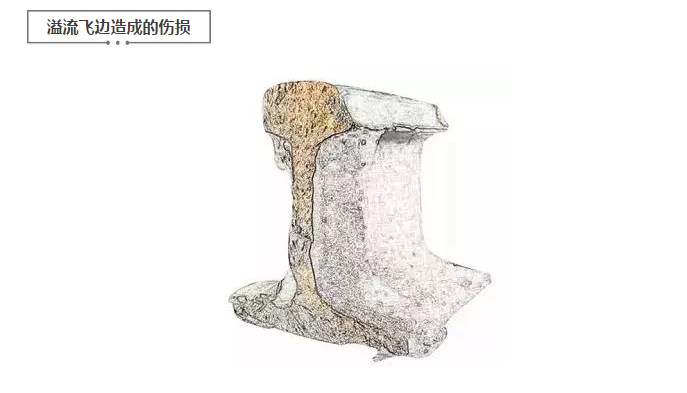

In the welding process of rail thermite weld, due to the non-implementation of the standard operation, the sealing is not strict, and the poor fit between the sand mold and the rail will lead to the flux outflow, thereby forming overflow flash at the edge of the weld, and the existence of overflow flash will lead to stress concentration and fatigue damage at the weld, which will eventually lead to the occurrence of rail breakage, which seriously affects the safety of train operation.

Rail breakage caused by stress relief and poor line maintenance

Rail flaw detection

Due to the inaccurate locking temperature of the rail, especially in the low temperature season, the rail is subjected to huge tensile stress, coupled with the impact force of the train, which accelerates the fatigue damage of the rail, resulting in the breaking of the rail. If the line is poorly maintained, the track bed is stiffened, the slurry is empty, and the connecting parts fail, etc., it will also accelerate the fatigue damage of the rail, resulting in rail breakage.