measurement challenge

In order to effectively control the thickness of thin coatings during anodizing, accurate non-destructive means of measurement are required.

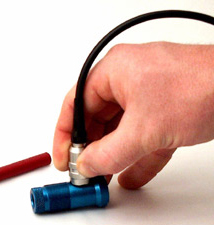

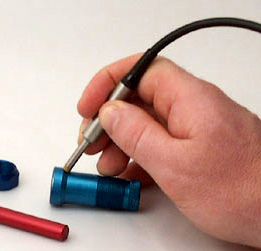

A secondary challenge is measuring anodization in small or hard-to-reach areas.

Coating Thickness Measurement Solutions

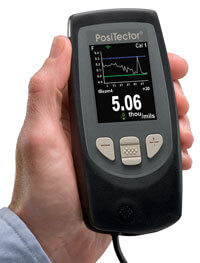

The PosiTector 6000 "N" Series Eddy Current Meter is suitable for the non-destructive measurement of non-conductive coatings on non-ferrous substrates. PosiTector NAS probes are designed for high-resolution measurements of anodizing aluminum. NAS probes are capable of measuring densities up to 625 μm (25 mils) with the highest accuracy and can provide the highest resolution down to 100 μm (4 mils), which is within the expected range for most anodizing applications.

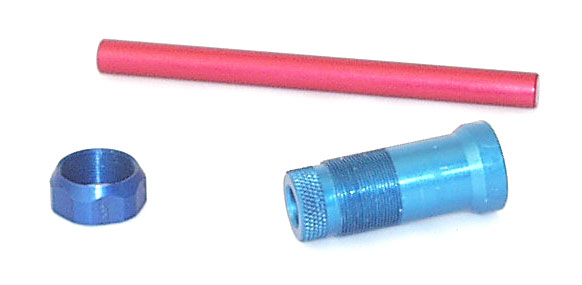

figure 1

figure 2

anodized background

What is anodizing?

Anodizing is an electrochemical conversion process that has existed since the 1930s. Several metals can be anodized, including aluminum, magnesium, titanium and tantalum. Anodized aluminum is used in many applications due to its low cost, aesthetic quality and desirable mechanical properties.

Unlike most protective coatings, anodizing permanently changes the external structure of the metal. When aluminum is exposed to air, it naturally forms a thin aluminum oxide film that seals the aluminum from further oxidation. The anodizing process makes the oxide surface thicker, up to a few thousandths of an inch thick. The anodized aluminum coating has a hardness comparable to diamond, enhancing the wear resistance of aluminum. The added depth of the oxide layer increases the corrosion resistance of the aluminum while making it easier to clean the surface. The porous nature of certain types of anodizing makes it possible to dye the aluminum in various colors, making it more attractive.

Anodizing is typically up to 5 mils thick. Three common variations of aluminum anodizing include chromium (Type I), sulfuric (Type II) and hard (Type III).

Þ Chromium anodizing utilizes a chromic acid electrolyte to produce the thinnest coatings available, only 0.02 to 0.1 mil (0.5 to 2.5 microns) thick. 50% penetration into the substrate, 50% growth beyond original size. Chromate anodizing has the least impact on fatigue strength and is less corrosive, making it ideal for intricate and difficult-to-wash components. Most chrome anodized parts are used in military and aerospace applications and are more decorative than natural.

ÞSulfuric acid anodizing is a common anodizing method that utilizes sulfuric acid to produce coatings up to 1 mil (25 microns) thick. 67% penetration and 33% original size growth. Due to its permeability, sulfuric acid anodizing is excellent for staining and provides a base for primers, adhesives and organic coatings. Sulfide anodizing provides corrosion resistance and is extremely durable. Typical applications include construction, aerospace, manufacturing automobiles and computers.

•Hard anodizing (also known as hard coating) uses a higher concentration of sulfuric acid electrolyte at a lower temperature to form a hard outer layer with good wear resistance, corrosion resistance, and fading resistance, Dielectric strength and surface hardness (Rockwell C-Scale up to 70). For a total thickness of 0.5 to 4 mils, 50% penetrates into the substrate and grows 50% over the original dimension. Hard anodizing metals increases surface roughness. Common uses include non-decorative food packaging equipment, copier paper rolls, and exterior applications such as architectural storefronts and windows.

Aluminum anodizing process

Aluminum components are suspended from stripped aluminum or titanium brackets, ensuring good electrical contact. Throughout the anodizing process, components are secured and racks are suspended in a series of tanks.

1. Immerse the aluminum part in a tank of hot water containing soak cleaner to remove all surface soiling.

2. Wash the parts to avoid contaminating the solution in subsequent tanks.

3. The next tank removes the thin and uneven surface with an acid solution (chromium, sulfuric acid, nitric acid or phosphoric acid).

4. Rinse the parts again to avoid tank contamination.

5. Etching is performed by suspending the part in a bath containing a sodium hydroxide solution. Etching removes the natural luster of aluminum and provides a soft, matte, textured look.

6. The part is suspended in an anodizing bath containing a dilute acid and water mixture that allows the flow of electrical current. The type of acid, solution percentage and temperature are all critical parameters and depend on the desired surface finish and color. The negative side of the circuit is connected to the frame of the component and the positive side of the circuit is connected to one or more

7. To add color (dye), dip the part into a bath with diluted water-soluble organic dye. Each dye varies in soaking time and temperature.

8.在阳极氧化过程中最后的考虑是密封现在染色的外表面,以免日光漂白或污染。未密封,多孔的外表面具有较低的耐腐蚀性。对于未染色的涂层,将阳极氧化铝部件放入煮沸的去离子水中20至30分钟。这将氧化铝的非结构化孔隙转化为更固体的结晶水合物形式。如果阳极氧化部件被染色,则密封过程在具有醋酸镍溶液的槽中进行3到5分钟。

9.According to工艺的不同,硬质阳极氧化使用硫酸和草酸的混合物。使用相对较低的温度以及较高的电流和较高的电压。所产生的“灰色”氧化层通常为2至3密耳,并且非常致密,耐磨且耐腐蚀。

大型阳极氧化更适用于阳极氧化小型不规则形状的部件,如铆钉,套圈和医疗中心。零件采用多孔铝,塑料或钛篮加工而不是机架。无论您需要卷材还是批量生产,阳极氧化都可以提供业内很好的的铝加工选项之一。

另一种选择是线圈阳极氧化。卷材铝经过预阳极氧化处理以降低整理成本,节省生产时间并减少材料处理。预阳极氧化铝的优点可应用于大多数由片材或卷材制成的产品。由挤压件,铸件,杆棒或钢板制成的产品限于支架阳极氧化工艺,如货架或散装。

尽管大多数铝合金会在阳极氧化槽中制造氧化铝,但它们倾向于不同的阳极氧化。一些合金更难以阳极氧化,而另一些则阳极氧化成略微不同的颜色。当阳极氧化时,各种合金提供不同程度的可加工性(加工,研磨,抛光),耐环境性能和尺寸稳定性。

为什么要阳极氧化?

阳极氧化是精加工铝的一种非常有效和称心的手段。阳极氧化的一些主要优点包括:

Þ耐用性 - 大多数阳极氧化部件在处理,安装,使用和维护过程中不会出现磨损。附着力 - 阳极氧化是铝的一部分,可实现完全粘合和很好的粘合。

Þ颜色 - 阳极氧化部件在暴露于紫外线时保持良好的颜色稳定性,没有施加涂层,易于碎裂或剥落,并且具有可重复的着色过程。

Þ原始表面处理的质量 - 零件不受原始阳极氧化处理标记。

Þ维护 - 温和的肥皂水清洁通常会使阳极氧化轮廓恢复原貌。

Þ美学 - 阳极氧化提供了大量的光泽和颜色替代品,同时允许挤出铝的金属外观通过。

Þ成本 - 与其他整理方法相比,阳极氧化是一种非常具有成本效益的价值。除了低加工和维护成本外,耐用性还可以降低更换成本。

Þ环境,健康和安全 - 阳极氧化有利于当前的政府法规,因为它是环保的工业过程之一,通常对人体健康无害。阳极氧化表面化学性质稳定,不会分解,无毒,对铝的熔点具有耐热性。由于阳极氧化过程是对自然发生的氧化过程的补强,因此它是无害的,不会产生有害或危险的副产品。阳极氧化过程中使用的化学浴通常被回收,回收和再利用。

为什么要测量?

阳极氧化工艺参数对形成的氧化物的性质具有显着的影响。 如果使用低温和酸浓度,则会产生较少的多孔和较硬的涂层。 更高的温度和酸含量以及更长的浸泡时间可以产生更柔软,更多孔的涂层。 合金本身或任何这些参数的微小变化都会显着影响涂层。

通过各种过程控制和测量技术,阳极氧化器能够监测,控制和校正阳极氧化涂层应用。 阳极氧化最关键的质量控制之一是厚度。 阳极氧化的厚度可以使用涡流计进行无损测量,也可以通过计算每单位面积的重量进行测量。 涡流方法的简单性不仅比计算方法更有效,而且还使检查员能够验证在零件的所有表面上发生了足够的阳极氧化。

市场在哪里?

成千上万的商业,工业和消费者应用中使用阳极氧化产品和组件:

- 建筑产品(幕墙,屋面系统)

- 商业和住宅产品(通风口,遮篷,框架,固定装置)

- 家电(冰箱,微波炉,咖啡机)

- 食物准备设备(平底锅,冷却器,烤架)

- 家庭和办公室家具(桌子,床,橱柜)

- 体育用品(高尔夫球车,小船,露营和捕鱼设备)

- 汽车组件(装饰,轮毂罩,面板,铭牌)

- 电子产品(电视机,摄影器材)

- 航空航天(卫星面板)

协会

AAC(铝阳极氧化剂委员会)

AEC(铝挤压协会)

AAMA(美国建筑制造商协会)

铝协会

行业规范

军事

MIL-A-8625 - 铝和铝合金阳极涂层

MIL-STD-171 - 表面处理和处理标准

ASTM

B244-97 Standard Test Method for Measuring Thickness of Anodic Coatings of Aluminum and Other Nonconductive Coatings on Nonmagnetic Base Metals by Eddy Current Apparatus

B487-85 Standard Test Method for Measuring Thickness of Metal and Oxide Coatings by Microscopic Examination of Cross Sections

B137-95 Standard Test Method for Measuring Coating Mass Per Unit Area on Anodically Coated Aluminum

B136-84 Standard Method for Measuring Stain Resistance of Aluminum Anodic Coatings

B457-67 Standard Test Method for Impedance Measurement of Anodized Films on Aluminum Alloys

B580-79 Standard Specification for Anodic Oxide Coatings on Aluminum

B680-80 Standard Test Method for Sealing Quality of Anodic Coatings Dissolved on Aluminum by Acid

B893-98 Specification for Magnesium Hard Coating Anodizing for Engineering Applications

SAE International AMS (Aerospace Materials Specification)

AMS2468 - Hard Coating Treatment of Aluminum Alloys

AMS2469 - Hardcoating of Aluminum and Aluminum Alloys

AMS2471 - Sulfuric acid process for anodizing aluminum alloys, without process

AMS2472 - Sulfuric acid process for anodized aluminum alloy, process dyeing

AMS-A-8625 (copy of MIL-A-8625)

international standard

ISO 7599 Anodizing of aluminum and its alloys; General specification for anodic oxidation coatings on aluminum alloys

ISO8078 Anodizing of aluminum alloys - sulfuric acid treatment, unpigmented coating

ISO8079 Anodizing of aluminum alloys - sulfuric acid process, dyed coating

ISO 10074 Specification for hard anodizing coatings on aluminum and its alloys

BS/DIN EN 2101 Specification for chromic acid anodizing treatments of aluminum and wrought aluminum alloys

BS/DIN 2284 Specification for sulfuric acid anodizing of aluminum and wrought aluminum alloys

BS/DIN 2536 Hard Anodizing of Aluminum Alloys

BS/DIN 2808 Anodized Titanium and Titanium Alloys

DIN EN 12373-1 Aluminum and aluminum alloys - Anodized

AAMA

AAMA 2604 - Voluntary Specification, Performance Requirements, and Test Procedures for High-Performance Organic Coatings on Aluminum Extrusions and Panels

AAMA 611 - Voluntary Specification for Anodized Architectural Aluminum