As might be expected, there are almost as many procedures for cleaning and preparing plastic surfaces as there are polymer types. Some procedures are cheap and easy to complete; others are not. There are some highly recommended procedures for most plastic types to get a great coating finish, but users are often faced with many equally valid options, or worse, conflicting advice on strength levels.

Plastics are available in many forms: mouldings, sheets, formed parts, foams and films. Many polymers can be easily blended together to achieve specific properties. Fillers and plasticizers are also included in the resin matrix to impart certain properties. Obviously, the same finishing procedure may not work in every situation, even if the main ingredients remain the same.

Manufacturers of plastics and coatings should be prepared to provide advice on appropriate surface preparation techniques to be used with the product. However, even manufacturers may not have a clear answer for individual situations, since user needs vary widely. Considerable experimentation may be required to determine the appropriate technique for a given operation.

The procedures outlined in the remainder of this chapter focus on technology, not plastic. However, where appropriate, certain technologies list the polymer types for which they are suitable.

Finally, many processes use hazardous, corrosive, toxic, flammable, or toxic chemicals, and safe handling methods, worker training, and proper control procedures cannot be overstated in their importance in reducing risk in the work environment.

solvent cleaning

Solvent action removes surface contamination by dissolving unwanted substances. This is a simple and common procedure, often the first step in a more complex procedure.

Organic solvents and water are suggested solvents. Organic solvents can be flammable or nonflammable. Commonly used in plastics are acetone, methyl ethyl ketone, isopropanol, methanol, toluene, 1,1,1-trichloroethane, naphtha, and sometimes Freon (either alone or mixed with other solvents). Water is cheap and readily available, but often has traces of impurities, which can also stain surfaces. Distilled or deionized water is most often suggested. Water is often used as a rinse agent for other surface preparation procedures.

These solvents can be used in processes as simple as wiping a damp cloth on plastic. Soaking is a technique usually done by dipping the part in a whirlpool bath and applying heat

Used to accelerate solvent action. Spray cleaning has the advantage of using spray force to remove contamination. Vapor degreasing requires plastic parts to hang over tanks of boiling solvent. As steam condenses on the part, a constant flow over the surface washes it clean.

Ultrasonic degreasing uses the high-frequency vibrations of sound waves to remove contaminants from a solvent bath.

In all cases, it is recommended that the solvent be changed or filtered frequently to prevent residue buildup and recontamination. Compatibility of solvents with plastics should be effectively checked. Care should be taken as some plastics absorb water. Heat is often used to dry parts after cleaning, but heat can easily deform thermoplastics.

detergent cleaning

What soap and detergent do in plastic parts is done in household dishwashers and washing machines.

Emulsification of oils, greases and some release agents is easily achieved in hot water or cold water. Detergent cleaning is often used as a preliminary step in mechanical treatment.

Cleaners are familiar names because they often find items in your home. Ivory soap, Ajax, borax, and trisodium phosphate are all suggested for various cleaning operations and do a good job.

Immersion cleaning is very effective unless the plastic is water sensitive. Scrubbing with medium-firm bristles is great for removing many contaminants.

Cleanliness needs to be monitored. Rinse with clean water is required as soap can act as a contaminant if not rinsed off. High heat is recommended for effective drying.

mechanical therapy

Physical scrubbing of plastic surfaces removes oxide and contamination layers. Professional solvent cleaning or detergent cleaning is required prior to mechanical treatment to avoid scrubbing surface contaminants into the rough surface. This process usually precedes chemical treatment.

Sanding, whether wet or dry, is a common process, using a 40-400 grit size, depending on the amount of surface to be removed and the desired finish. Softer plastics are obviously more susceptible to damage. For parts with complex configurations, sandblasting (wet or dry) or wire

Brushing your teeth is more appropriate. The size and type of grit can be varied to obtain the proper finish. Processing can be used to expose fresh layers of plastic for coating.

In all cases, rough surfaces should be vacuumed or air blown to remove residual dust or grit.

Solvent wipes or water rinses followed by high heat drying are also recommended.

chemical treatment

Typically, an effective surface treatment is chemical etching of the plastic to be coated. Both physical and chemical properties can be altered to improve wetting and film adhesion. Chemical treatment is almost always preceded by one or more cleaning operations to remove surface contamination.

These previous manipulations reduce solution contamination and ensure a good interaction between solution and substrate

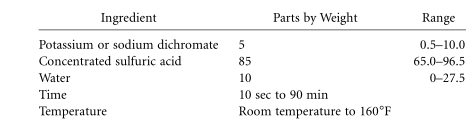

Typically, surfaces are washed or immersed in baths containing acids, bases, oxidizing agents, chlorinating agents or other highly reactive chemicals. Each procedure requires control of the parts by weight of the active ingredient, the temperature of the solution and the elapsed time of impregnation. Some programs have broad ingredient ratios, while others are quite specific. The temperature of the solution is inversely proportional to the immersion time; that is, the higher the temperature, the shorter the exposure.

Almost all chemical etching processes require a water rinse (once or twice) and high heat drying is recommended. For active ingredient treatments, the solution strength needs to be monitored and updated at appropriate intervals.

1) Sulfuric acid - dichromate etching

The recommended chemical treatments for plastic parts commonly used so far are in acrylonitrile-butadiene styrene (ABS), acetal, melamine or urea, polyolefins, polyphenylene ether, polystyrene, polysulfone and styrene - Acrylonitrile (SAN). For each plastic, different ingredient ratios and soaking temperatures and times are recommended.

The following list serves as a guide to the possible parameter ranges:

While the range is very broad, experimental trials combined with test results allow the user to determine the most appropriate value for a given plastic.

2) Sodium etchant

For really difficult surface coatings, such as various fluoroplastics and some thermoplastic polyesters, highly reactive materials are required. Sodium metal (2 to 4 parts) is dispersed in a mixture of naphthalene (10 to 12 parts) and tetrahydrofuran (85 to 87 parts).

The soak time is approximately 15 minutes at ambient temperature, followed by an effective solvent (ketone) rinse before water rinse.

3) Sodium hydroxide

A mixture of 20 parts by weight sodium hydroxide and 80 parts water is effective for the treatment of thermoplastic polyesters, polyamides and polysulfones. It is appropriate to heat the solution to 175 to 200°F and soak for 2 to 10 minutes.

4) Satinizing

Satinizing is a process developed by DuPont for its homopolymer grade acetals (US Patent 3,235,426). Dip the part in a heated solution of dioxane, p-toluenesulfonic acid, perchlorethylene and thickener. After the immersion cycle, the parts are heat treated, rinsed and dried according to the prescribed procedures.

5) Phenol

Nylon is usually etched with 80% phenol in water. Typically, treatment is done by brushing on the surface and drying at about 150°F for about 20 minutes at room temperature.

6) Sodium hypochlorite

Many plastics, especially thermoplastics and newer thermoplastic rubbers, can be chlorinated on the surface by using a solution (parts by weight) of the following composition:

Water: 95 to 97

Sodium hypochlorite, 15%: 2 to 3

Concentrated hydrochloric acid: 1 to 2

Parts can be soaked at room temperature for 5 to 10 minutes, or the solution can be brushed on the surface for the same time.

Other processing

There are various other cleaning and prep techniques. Many of these procedures are unique to plastics processing and were developed to overcome the low surface activity exhibited by many plastics. To achieve good results in most cases, these treatments require solvent removal of surface contaminants first

or detergent cleaning.

1) Primers

A primer is an adhesion-promoting coating used to create better adhesion of the final coating to the plastic substrate. Primers can be of any number of chemical types including silane, polyurethane polymer, isocyanate, nitrile phenolic or vinyl. To protect the substrate from recontamination, it is often necessary to apply a primer to the surface after other surface preparation procedures have been completed.

2) Flame Healing

The impingement of many plastics, such as polyolefins, acetals, fluoropolymers, and polycarbonates, to the flame oxidizes the surface, providing higher levels of surface energy and better film adhesion.

This process can be especially effective on complex shapes and molded parts. Superheated air (1000°F) performs the same function as a flame.

3) Exposure to UV radiation

High intensity radiation from UV sources provides ionized or highly polar surfaces.

4) dry

Since many plastics readily absorb moisture from the atmosphere, simple oven drying may be effective

5) Plasma treatment

Most plastics benefit from plasma treatment. The parts are exposed to the gas, which is ionized by radio frequency or microwave discharge. Valid gases include neon, helium, oxygen and moisture.

Although very effective at modifying surface conditions to improve film adhesion, the process is often limited by equipment limitations for smaller assemblies and components.

6) Corona discharge

For films and other thin gauge plastics, surface tension can be improved by passing between two electrodes.

This processing is suitable for high-speed operation.