The extensive series of tests carried out on the pilot plant are described below:

A fluorine concentration of 5-10 vol% in the plenum is quite sufficient to raise the surface energy of the polymer to above 50 mN/m.

The average fluorine consumption for pretreating about 100,000 square meters of polymer surface is only 2.5 kg. (Fluorine costs are practically negligible.)

All tests described below were carried out at a working width of 1 m; the length of the reaction chamber entering the fluorine nitrogen was 1 m, the height was 30 cm, and the volume was 300 liters.

polyethylene vinyl acetate copolymer foam

1 mm thick closed cell foam is preconditioned on both sides with a web speed of 5 m/min.

After passing through fluorine gas, the surface tension of the foam increased from 30mN/m to 54mN/m. If the foam is used as a support material, for example for double-sided pressure sensitive tapes, the adhesive bond is as good as the corona pretreated material. This is shown in Table 41.1.

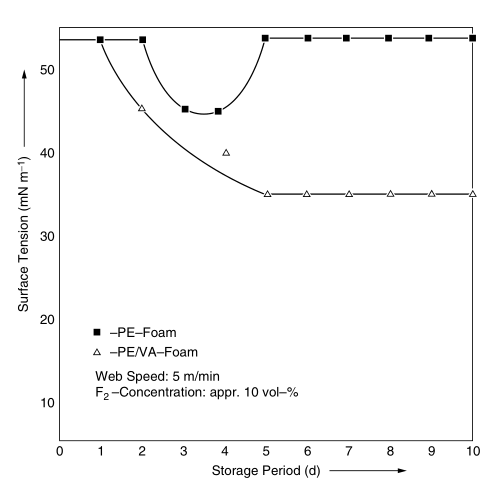

Electron spectroscopy for chemical analysis (ESCA) studies8 indicated that the activation of the foam selected in this example was mainly based on the partial fluorination of the terminal methyl groups of the comonomer vinyl acetate. As with corona pretreatment, the surface tension decreases gradually, but it stabilizes at higher levels, as shown in Figure 41.3. However, pure polyethylene foam maintains an imparted surface tension in excess of 50 mN/m for several weeks.

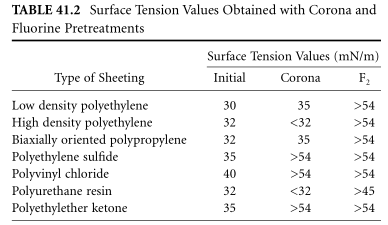

plastic sheet

At a pilot plant up to a maximum web speed of 24 m/min (F2 concentration 5 vol%), common film or sheet qualities of different widths were successfully pretreated on one or both sides as shown in Table 41.2. The effect of pretreatment remained constant during the 6-week observation period.

air spacer

For some applications, the adhesive coating applied on the bit side needs to adhere firmly to the surface of the sheet or film, even in gaps. Here, the fluorination technology is in fact,

Storage stability of surface energy of polyethylene (PE) and PE-vinyl acetate (VA) copolymer foams pretreated with fluorine.

Destined to be the solution to the problem. As expected, this polyethylene air gasket or film can be pretreated as well as other polyethylene sheets.

Terpolymer Rubber

Ethylene propylene monomer (EPDM) is among the materials that will be used more and more in the future - especially in the automotive industry.

A negative aspect of this versatile, nearly indestructible polymer body is its stubborn preconditioning behavior. Therefore, only 45 mN/m was measured after section cutting of EPDM conveyed through the fluorination chamber on the endless belt. However, this surface ensures satisfactory substrate adhesion.

Advantages of fluorine surface pretreatment

Compared to other pretreatment processes, fluorination not only has a wide range of applications, but unlike corona pretreatment and ozone treatment, it does not require electrical equipment that is susceptible to interference and requires a lot of maintenance. In addition, the basic investment of fluorine accessories (unloading station) and reaction chamber is lower than the main cost of corona pretreatment station.

A particular advantage of continuous fluorination can be seen when applied to webs, which cannot be performed with prior art means when wound from compact rolls. This material can now be surface activated continuously from roll to roll, independent of roll length.

Another very important argument for fluorination technology is that, unlike corona pretreatment, the surface treatment effect is durable - and better yet irreversible - on both sides. This is of great importance for practical applications in industry, since the subsequent surface refining process does not require immediate surface activation.

In addition, the fluorination process provides an effective pretreatment of the following materials:

• Debossed, embossed or other irregularly shaped surfaces of sheet metal or film

• Narrow fabrics

• Foam wider than 2mm

• Biaxially oriented polypropylene film of any width