There are more than 100 large and small brands of Coating Thickness Gauge at home and abroad, of which there are 65 on NBchao. Com Mall. We often face the same doubts of customers. How should I choose? Once we wondered for a long time, because we developed a Coating Thickness Gauge selector based on user selection, which can be foolish to determine which instruments are suitable and which instruments are not suitable according to his application environment and requirements. In the process of use, the general user response is very intuitive, which is simpler than the salesperson's explanation.

However, unfortunately, the customer still expressed the above doubts to us: How should I choose?

Later, I found out that it is not that the user does not know whether this Coating Thickness Gauge can satisfy him. This can be defined through the nbchao selection system. What the user wants to know is that there are 500 or 600 Coating Thickness Gauges in your mall, and 100 of them meet his requirements. How should he choose? And our consistent principle is not to take the initiative to suggest brands to customers, no matter whether the brand earns more or less, it can objectively present advantages. What can be done?

My colleague asked me to write an article on how to choose a Thickness Gauge. After thinking about it, I defined which test method, accuracy, and range to choose and handed it over to the system. Different application environments, special shapes, and corresponding solutions are applied. It is estimated that users have also seen it. Therefore, I would like to share with you that Thickness Gauges at different prices are cheap and expensive, and solve problems that users cannot solve according to the system.

The difference between expensive and cheap

1. Accuracy of measurement

This trick is relatively big, I excerpted a paragraph from defelsko's official English statement as the beginning:

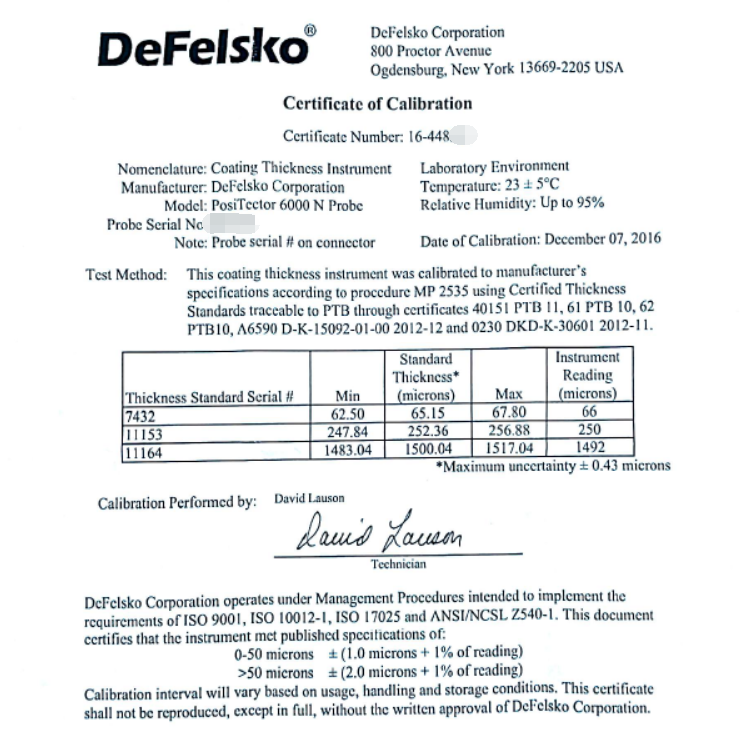

PosiTector 6000 instruments arrive fully calibrated and include a Long-Form Certificate of Calibration traceable to NIST or PTB. The Certificate of Calibration documents actual readings taken by your instrument at our calibration laboratory, on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

See? The "accuracy" marked by the daily Coating Thickness Gauge is not necessarily the real "accuracy". Sometimes some merchants randomly mark a high precision in order to highlight the cost performance, because they know that most users will not take it to Measurement. And once they find that customers ask if they can pass the Measurement, they castrate.

This is a very common example. There is a world of difference between a calibrate certificate with traceability and an instrument with a manual cover of "product qualification". In order to pass the accuracy recognized by a third-party organization, the effort and cost behind its Product Research & Development are invisible to everyone. Therefore, it seems that adding a certificate, the actual cost is not this piece of paper, but represents the investment behind it and the confidence of the product.

A relatively negative example can prove my above statement. A few years ago, the sales manager of a manufacturer came to us and wanted nbchao to sell each other's things. When talking about the selling point of the product, the sales manager even smiled disdainfully and said, I can write as much precision as you want. Everyone knows this... I was so surprised at the time that I was speechless. Later, we have no later.

2. Probe

The probe is not tricky, but it is indeed what you get for every penny. In order to illustrate this problem, I specially found more than ten Coating Thickness Gauges to carefully observe their probes. Let's start with a real case that happened a few days ago and a specially compared probe picture to make it clear to everyone:

The probe is not tricky, but it is indeed what you get for every penny. In order to illustrate this problem, I specially found more than ten Coating Thickness Gauges to carefully observe their probes. Let's start with a real case that happened a few days ago and a specially compared probe picture to make it clear to everyone:

Case: [Customer] I bought a XXX Thickness Gauge more than a year ago, and now the probe feels seriously worn (we use it quite frequently). I see that you have agents of many Thickness Gauge brands. I would like to ask if you have this separate probe for sale?

Honestly, as far as the sensitivity of the probe is concerned, the high, medium and low-end products on the market can meet the daily requirements. The main price difference lies in the material and process. Take the Defelsko FNS probe with relatively high awareness on the market as an example. The probe is fully sealed in stainless steel, which can be placed in water for measurement, resistant to solvents, acids, oil, water and dust and other measurement environments. The Sensors material in the middle of the probe is ruby, which greatly improves the wear resistance of the Sensors and the durability of the calibrate. Maybe the text is difficult for everyone to have a deep understanding. For this reason, we took a picture. This picture is more related, because the Defelsko FNS probe here has indeed been used for more than 10 years. Usually, laboratory measurements use this machine and this matching probe. Compared with it in the middle is a certain brand of Thickness Gauge probe that has just been unpacked for a few days, and another imported Thickness Gauge on the right. Due to the problem of the machine, it has been scrapped in the warehouse and cannot be measured, but it has been more than seven or eight years.

This picture actually wants to tell you that when choosing the Coating Thickness Gauge, the parameters really need to be paid attention to, but if the probe quality is good, the machine can not only prolong the life, but also will not lose accuracy. There is no problem with the customer mentioned in Case.

3. Function

The difference between software functions is actually easier to understand. Most of them are manifested in whether there is software, how is the analysis and statistical function of the software, the convenience of data export, the amount of data storage, and the statistical dimension of the screen display data (for example, some can display real-time film thickness Linear dispersion fluctuation map)

Personally, I don't think there is much to add, there are many online.

It is worth mentioning that the measurement function of some machines can be single-point uninterrupted measurement, or "sliding" measurement, which is not available on low-end products. Even if there is, the probe will be gameover after grinding back and forth dozens of times. But it is matched on some high-end imported brands. What are the benefits? Single-point uninterrupted measurement can more rigorously evaluate the fluctuation of test data at the test point, and better obtain accurate measurement values. And "sliding" measurement can better evaluate the fluctuation of a surface coated Film thickness.

4. Durability

The hardware function is mainly the protection performance of the fuselage. For more complex environments such as dust/humidity, the general machine is really not used for a long time, and even in extreme cases, explosion-proof products such as pull-off Thickness Gauges should be considered. When I was fortunate enough to participate in the training meeting of Defelsko, how did the instructor on site prove the durability of the machine? Throw a few back and forth directly to the ground, unscathed. Of course, I dare not do this experiment myself. Believe it or not is one thing, but it is money anyway. If it is not accidentally dropped, who has nothing to do and throws the machine to vent!

5. Conclusion

All in all, in product selection, the Coating Thickness Gauge must first define the material of the substrate + coating, and define the measurement method/accuracy/range through the Coating Thickness Gauge selection tool developed by NBchao. Com Mall, and then select the corresponding probe according to different harsh environments, such as measuring corners, measuring high temperature, measuring rough surface, measuring underwater, etc. After eliminating the batch, buy it reasonably according to the purchase budget, pay special attention to the issue of accuracy. As for durability and function, this is what you love. Some people would rather wear shoes for 30 yuan every three months, and some people would rather buy shoes for 300 yuan every three years. Just be comfortable.

Author: Air

20118/7/6 NBchao. Com Mall reprint please indicate