The vacuum Drying Oven is specially designed for drying heat-sensitive, easily decomposed and easily oxidized substances, and can be filled with inert gas inside, especially some items with complex components can also be dried quickly. Widely used in electronics and chemical industries. Due to the nature of the work, the author observed that many enterprises did not understand the difference between the vacuum Drying Oven and the ordinary Drying Oven when using the vacuum Drying Oven , so they could not accurately control the temperature of the vacuum Drying Oven and use the Drying Oven correctly. In order to help the users of the vacuum Drying Oven to use the vacuum Drying Oven correctly and accurately evaluate the temperature field during the use of the vacuum Drying Oven, it is necessary to introduce the principle and structure of the vacuum Drying Oven, combined with years of experience in temperature measurement Talk about the measurement method of the temperature field of the vacuum Drying Oven.

1 Principle and structure

The shape of the vacuum Drying Oven is mostly horizontal, and the material of the working chamber is made of stainless steel plate or high-quality steel plate. The shape is mostly square, and there are also cylindrical shapes. The cabinet is mostly made of high-quality steel plate sprayed , and the ultra-fine glass wool is filled with the middle insulation layer. Most of the cabinet doors adopt double-layer glass doors, the inner layer is tempered glass over 12 mm, and the outer layer is bulletproof glass or plexiglass. A molded heat-resistant silicone rubber sealing ring is installed between the working room and the outer door, thereby ensuring the sealing between the box door and the working room, and greatly improving the vacuum degree of the box [1].

The heaters of domestic vacuum Drying Ovens mostly use electric heating tubes to be placed directly at the bottom of , covered with steel plates, and placed to be dried samples, and the temperature sensor is placed under the steel plates close to the steel plates. Some imported vacuum Drying Ovens place the heating wire in the interlayer of the steel shelf , and the temperature sensor is also sealed into the shelf.

In the national standard, the general electric heating (blast) Drying Oven has temperature uniformity parameters, but the electric heating vacuum Drying Oven does not set the temperature uniformity parameter [2], this is because the vacuum Drying Oven depends on the movement of gas molecules to make the temperature uniformity parameter. The possibility of achieving a uniform temperature in the studio is almost gone. The vacuum Drying Oven heats the objects placed in the oven by thermal radiation. The amount of thermal radiation is inversely proportional to the square of the distance. For the same object, the radiant heat received at a distance of 20 cm from the heating wall is only 1/4 of that at a distance of 10 cm from the heating wall, and the difference is very large. Structurally , it is difficult to make each point (spherical surface) in the three-dimensional space of the working room radiate heat evenly .

2 Correct use of vacuum Drying Oven

When using the vacuum Drying Oven, be sure to draw a vacuum first and then heat the box . This is because (1) if heated first, the gas in the box will expand when heated. Since the vacuum box is very well sealed, the huge pressure generated by the expanding gas may burst the tempered glass of the observation window. This is a potential danger. (2) If you operate according to the procedure of first heating up and then vacuuming, when the heated air is pumped out by the Vacuum Pump, the heat will inevitably be brought into the Vacuum Pump, which will cause the temperature rise of the Vacuum Pump to be too high, which may make the Vacuum Pump Efficiency drops. (3) The heated gas is directed to the vacuum pressure gauge, and the vacuum pressure gauge will generate a temperature rise. If the temperature rise exceeds the specified operating temperature range of the vacuum pressure gauge, it may cause an error in the vacuum pressure gauge. The correct method of use should be to vacuumize and then heat up. After reaching the rated temperature, if you find that the vacuum degree has dropped, then pump it properly. Doing so is beneficial for prolonging the service life of the equipment.

3 Temperature measurement method

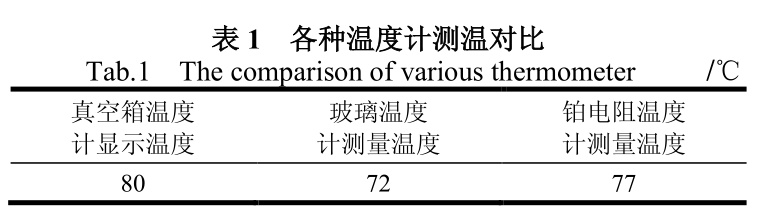

To measure the temperature field temperature of the vacuum Drying Oven, glass thermometers and platinum resistance thermometers (wireless) are used as reference thermometers, and the measuring points are pasted into the monitoring thermometer measuring points of the vacuum oven. The results are as follows:

If the platinum resistance thermometer is placed 10 cm away from the object shelf, the measured temperature is only 70 °C. Based on the analysis of the principle and structure of the vacuum box, it can be known that these sets of temperature data cannot represent the actual temperature of the vacuum box space and can only be used as a reference. The thermometer can only reflect the temperature generated by the sensor itself due to the absorption of thermal radiation. The amount of this heat radiation absorbed is closely related to the roughness of the sensor material surface and the material's ability to absorb, refract and transmit infrared radiation (the thermal engineering term "blackness") [3]. The closer the blackness of an object is to 1, the more radiant heat it absorbs, and the higher the temperature of the object. Otherwise it is low.

In the actual application of the vacuum Drying Oven, the effective way to control the temperature field in the oven to meet the required operating temperature is to change the radiation temperature measurement into contact temperature measurement. Contact temperature measurement is the most accurate temperature measurement method in the current temperature measurement methods . To achieve contact temperature measurement, first prepare a calibrated thermometer, which can Thermocouple Thermometer, platinum resistance thermometer, or a liquid-in-glass thermometer.

Prepare samples for drying. Because each vacuum Drying Oven is only suitable , it is recommended that users prepare all samples that may be used for drying, and load them according to the usual drying state. Or put it in a watch glass (mostly powdery samples), or put it in a beaker (solid granular samples), bury the reference thermometer in the sample, ensure that the measuring end is completely submerged in the sample, and not in contact with other surfaces, and then put it in Experiments were carried out in a vacuum oven. After the temperature field is stable, record the temperature and the reading of the reference thermometer, and record the surface state, quantity, and placement of the samples to be heated. It is also possible to prepare a few more thermometers and place them on the effective heating area of the sample shelf (at least 10 cm away from the inner wall of the box [4] ) according to the above-mentioned method , and record the temperature difference at each position of the shelf at one time. Find the correspondence between the temperature displayed on the vacuum chamber thermometer and the reference thermometer reading. If the vacuum oven is heated at multiple temperatures, perform the same experiment at each temperature point. After the drying is finished, check the drying effect, conduct final verification, and find the satisfactory control temperature point for each sample. Record this temperature point as the control temperature for drying samples in the future.

4 Conclusion

Most of the vacuum Drying Ovens are used improperly in practical applications, which may cause potential hazards and affect the drying effect. The vacuum Drying Ovens used in the laboratory will also affect the experimental data of the dried samples due to improper temperature control. This paper aims to solve these problems from the principle and test method of the vacuum box, and proposes an accurate temperature measurement method suitable for users