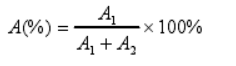

Determination of adhesion according to GB/T13217.7-91. The specific method is to use a wire Bar Coater to coat the sample on BOPP, dry it at 45-55°C and let it stand for 24 hours, then stick an adhesive tape on the printed film, and examine the surface state of the printed film after peeling off. Test result: cover the uncovered part with translucent grid paper with a width of 20mm. Count the number of squares occupied by the ink layer and the number of squares occupied by the removed ink layer. Calculate according to the formula:

In the formula:

A - ink adhesion fastness;

A1——the grid number of the ink layer

A2 - the grid number of the ink layer to be peeled off

in,

Good - more than 90% of the printing film remains;

Qualified - 60~90% of the printing film remains;

Poor - less than 60% of the printed film remains.