Real stone paint for exterior walls, as the name implies, is a kind of paint used in exterior wall systems. Real stone lacquer has a unique decorative effect, and it can be applied with a coating method to produce a coating film effect similar to decorative stone, which meets the same psychological requirements as wall tiles. Since real stone paint is a type of paint with a sandy wall and stone appearance on the film finish, it is also called sandy wall-like architectural paint, "stone paint", "stone-like paint", etc. Stone-like and antique are the trend of modern decoration, so it is also called It has become a more popular type of paint at present.

The wide application of real stone paint for exterior walls is based on a special decorative effect, which is a pursuit of beauty, so the requirements for the spraying effect of real stone paint are very high. The first step in the effect of real stone paint on exterior walls is the detection of the base layer. Here are five points:

1. Strength

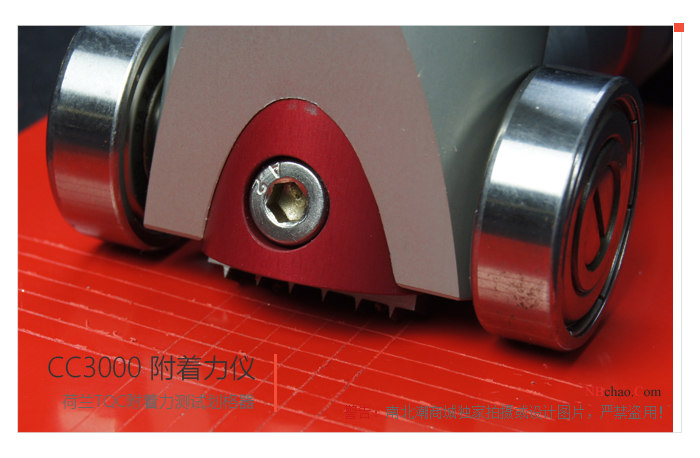

The strength of the base has a lot to do with the type and quality of the base. Generally, the concrete base has the highest strength, followed by mortar and gypsum board. If the strength of the base layer is too low, it will affect the adhesion of the coating (testing instrument: adhesion Tester). A qualified base layer should have no powder dropping, no sanding, no hollowing, layering, cracking and peeling.

2. Flatness

The unevenness of the base will affect the final decorative effect of real stone paint. There are four main items for flatness inspection: smooth surface, vertical yin and yang angles, vertical facade, and square yin and yang angles.

3. Dryness

The humidity of the base layer comes from the water added when mixing cement, and the moisture will bring alkaline substances to the surface and damage the coating. The base layer needs to dry effectively before painting. Moisture content needs to be less than 10%. Usually, for the cement mortar base, under the condition of good ventilation, the moisture content can reach the requirement within 14 days in summer and 28 days in winter.

4. pH

Lime in mortar, concrete, and cement contain a large amount of calcium hydroxide, which is very alkaline. The alkalinity of the base layer will affect the adhesion of the coating, and it will also cause quality accidents such as discoloration, air layer, whitening, and blooming of the coating. The pH value of the base layer should be less than 10.

5. Cleanliness

Remove laitance, dust, oil stains, etc. on the surface of the base layer, so that the surface is conducive to the bonding of the coating. Base treatment is the first and basic process of real stone paint painting, which has a decisive effect on the quality of the entire coating. If the treatment of the base layer is not in place, quality accidents such as coating peeling, cracking, and blooming will occur.

In addition, there is a problem in the construction of real stone paint that some new construction workers will wonder: should it be formed once or twice? The following is an analysis of this.

对于一次成型,其实会存在几个问题:1、对油漆的厚薄不易掌握。2、无法克服施工缺陷,这种缺陷有的是墙面造成的,有的是涂料配方造成的,如果不了解,一次成型麻烦就来了。3、一次成型因为出漆量太大喷出来往往不够平整,在真石漆较稀的情况下稍有不慎就会流挂(检测仪器:流挂仪)。

而二次成型可以在某些方面很好避开一次成型的问题,首先二次成型则可以针对前一道工序造成的问题采取挽救性施工;再者,二次成型就可以对施工风险起到防火墙的作用;另外,二次成型出漆量较少,扇面雾化效果好,喷出来比较平整,稍加打磨后手感要好很多。

| 喷漆枪网上直销商城 |

虽然很多人会认为二次施工耗漆量大,理论According to就是二次施工两次打在硬体墙面上反弹落地的石粉多。但According to一些老技术师傅的经验,其实一次施工和二次施工耗漆量差不多。因为一次施工的厚度不易掌握,往往喷得厚(因偷工减料有意喷薄的不算哟),二次施工雾化效果好,用漆量精准。另外对于黄色、红色、橙色、咖啡色这几种色尤其要二次成型,否则很容易“花”掉。

最后,下面是对外墙真石漆施工的5个常见问题进行分析:

1)上涂着色不平均

原因:着色配合掌得不准确,掺入的涂料不能准时均匀扩散起来,涂层的厚度不均匀所致;

解决措施:重新做二次的产品均匀调整,直致试面上的涂料有一定的质感。

2)涂漆表面泛起开裂以及空鼓现象

原因:重新做二次的产品平均调整真石漆,直致试面上的涂料有一定的质感。

解决措施:着色配合掌得不正确,掺入的涂料不能准时平均扩散起来,涂层的厚度不平均所致;

3)泛起大量的抹纹不平现象

原因:水泥砂浆面积大,造成干燥时间慢,这样会产生开裂以及空鼓现象;

解决措施:进行平均的分格处理,在基屋抹灰过程中,进行对砂浆均匀的配合。

4)接茬表面层显著

原因:喷涂产品成份过分,造成涂料表面过厚,底灰若抹得不够平坦;

Solution : Check and accept the cement mortar plastering according to the exchanged scale in due course. If it is not closed, the construction cannot be scheduled.

5) Existing cross-contamination is serious

Reason: The surface layer did not pay attention to the distribution on the grid during the construction process, resulting in the appearance of rolling;

Solution: During the construction process, every construction step must be followed to avoid cross-contamination damage as much as possible. At the same time, we can choose auxiliary coatings with anti-aging, high temperature resistance and strong radiation resistance to fill, which can also ensure cross-contamination reduction.