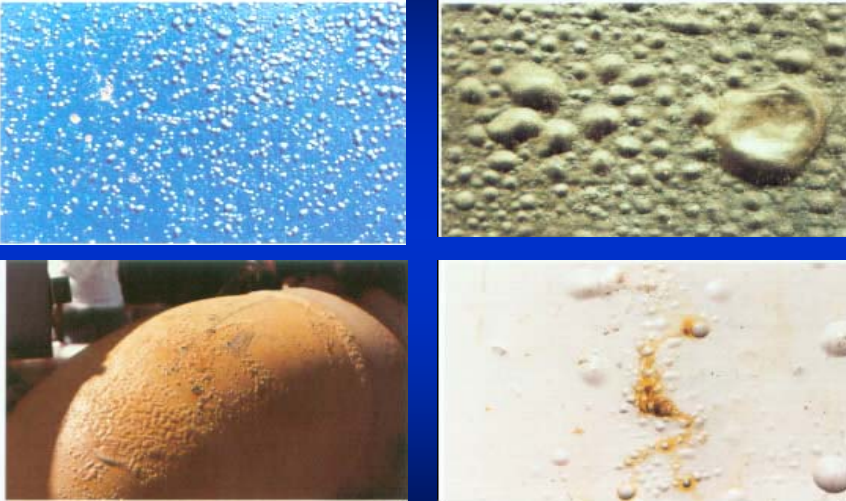

Coating blistering refers to dome-shaped protrusions or bubbles on a dried coating surface due to localized loss of adhesion of the topcoat to the underlying coating surface. This is a common coating defect in coatings. Coatings are not only for protection, but also for decorative aesthetics. Especially for high-end products such as construction, electronic appliances, furniture, and automobiles, the aesthetic requirements of the products are very high. Moreover, the coating is prone to blistering and peeling off.

So why does it cause the coating to blister? Primarily due to localized loss of adhesion due to pollution such as grease, rust, salt, entrapped moisture, residual solvents, hydrogen pressure (using cathodic protection), soluble pigments, etc., osmotic blistering occurs under water immersion conditions. In addition, overcurrent protection will also cause blistering.

The consequences of coating blisters are unquestionable, so what can be done to prevent them? This starts with ensuring proper surface preparation and paint application. Furthermore, use a suitable paint system to paint. In addition, suitable cathodic protection can also be used appropriately.

Sometimes no matter how to prevent and prevent, it is inevitable that there will be coating bubbles . If re-spray construction, sometimes the cost is relatively large. So how to fix it? Depending on the size and type of bubbles, parts of the bubbles can be removed or the entire paint system (as a last resort), repaired or repainted.