coating pinhole

Coating pinholes refer to some tiny but deep holes on the surface of the coating, which not only affects the protective effect of the coating, but also affects the aesthetics of the coating.

What is the principle of coating pinholes? During the construction and drying process of the paint, due to the expansion of the air or solvent-based gas mixed in the paint paint, many potholes and pinholes will be formed on the surface of the wet film before the coating dries.

Coating pinholes are mainly caused by the accumulation and release of solvent or air in the applied coating. Pinholes are especially common when applied over some porous coatings such as zinc primers, inorganic zinc paints and metal sprays. In addition, pinholes can also occur if the spraying method or solvent is not used correctly.

If you want to avoid the pinhole situation. Let's share the preventive measures: 1. Adopt the correct construction technology and choose the appropriate coating system. 2. Use suitable solvents and choose to construct under good environmental conditions. 3. Spraying equipment is also an influencing factor, and the spraying equipment is also checked periodically. 4. During the spraying process, keep a reasonable spraying distance between the Spray Gun and the surface.

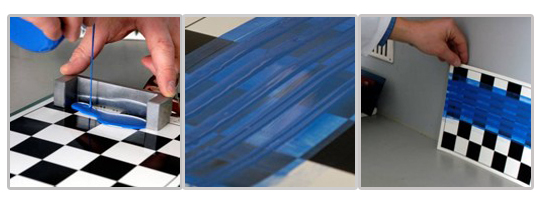

Finally, in the case of pinholes in the coating, the pinholes can be repaired by sanding, cleaning and using a suitable sealer/intermediate and topcoat.

coating sag

Coating sagging refers to the phenomenon that there are traces of paint liquid flowing downward on the coating film, which is a common coating defect. Shortly after the coating is applied, due to the thickness of the paint film, the paint will move downward or flow downward like tears in the vertical part. Sometimes the situation is serious, and the shape will be like a waterfall.

There are several causes of coating sag. 1. The sprayed coating is too thick, the solvent is too much or the curing agent is wrong; 2. The spraying technology is immature, the spraying distance is too close, and the spraying amount is too large; 3. The spraying construction environment is harsh, such as too cold or too hot. cause sagging.

So how to prevent the problem of coating sagging?

1. Use the correct coating system; 2. Use the correct spraying construction process; 3. Choose the correct dry film thickness.

For the situation that has caused the coating to sag, it can be repaired from the following measures:

Remove sag with a paint brush or roller when coat is wet; when coat is dry, sand and clean defective surfaces as needed, repaint or touch up.