The solid paint film formed after drying the paint applied on the surface of wood products and wooden materials for interior decoration will be used together with the products for many years, and should have a series of performances to achieve decorative protection for the products. The properties that a solid paint film should have mainly include adhesion, flexibility , liquid resistance (acid, alkali, water, beverage, solvent, other chemicals and other liquids), heat resistance, cold resistance, weather resistance, and temperature resistance of the paint film. Change, scratch resistance, impact resistance, abrasion resistance, gloss, hardness, gloss and color retention, freshness persistence, environmental protection, etc.

1. Adhesion

Adhesion refers to the ability of the paint film to be combined with the surface of the substrate to be coated or between coatings, also known as adhesion. Adhesion is an important technical index and a prerequisite for a series of properties of the paint film. The paint film with good adhesion is durable. A paint film with poor adhesion is easy to crack and fall off, making it unusable.

The factors that affect the adhesion of the paint film include the type of paint, the hardness of the film-forming substance, the finishing process, the nature of the surface to be painted, and so on.

Different types of paint have different adhesion of the paint film. Generally speaking, the oily paint with a softer paint film has better adhesion than the harder resin paint.

The use of different finishing processes also affects the adhesion. When choosing a heterogeneous composite coating, attention should be paid to the compatibility of the primer and topcoat. For example, when shellac paint was used as a primer in the early years, the polyester paint on it was easy to peel off; choose the same kind When compounding paint layers, some polymeric paints (such as polyurethane), when the previous coat is overdried and then the next paint is applied, the adhesion will be affected due to poor cross-linking between the coats. Therefore, in production, when the two-component polyurethane paint needs to be painted continuously for multiple times, it is advisable to adopt the process of surface drying and then painting, which is the so-called "wet-on-wet" finishing process. If the construction conditions require a long interval ( (such as overnight construction) when recoating, the surface of the paint film should be polished or wiped with a solvent before applying the next coat of paint.

The surface state of the substrate to be painted also affects the adhesion. For example, if the wood surface is not clean, there are oil stains, colloids, resins, dust, etc.; the moisture content of the wood is too high (greater than 15%) ; membrane adhesion.

2. Hardness

Hardness is the ability of a paint film to resist mechanical forces such as collisions, depressions, scratches, etc.

For various wood products that have been painted, the paint film becomes the outermost surface of the product, directly subjected to the external environment, and in contact with other objects, such as wooden floors, sofa armrests, various countertops, chair surfaces, carriage boards, basketball boards, table tennis Ball cases, etc., the surface paint of these parts should have higher hardness. The higher the hardness of the paint film, the higher the mechanical strength of the surface, the better the wear resistance, and the ability to withstand bumps, scratches, etc. Especially when grinding and polishing, the hard paint film is easy to throw off the luster, but the soft paint film generally cannot be polished. Therefore, for medium and high-grade wood products that need to be polished, it is necessary to use high-hardness coatings, such as nitro paint, polyurethane paint, polyester paint, etc. Generally, the paint film of phenolic paint and alkyd paint is relatively soft and has poor polishing and polishing properties. However, the higher the hardness of the paint film, the better. A hard paint film is prone to brittleness, which affects adhesion and has low impact strength.

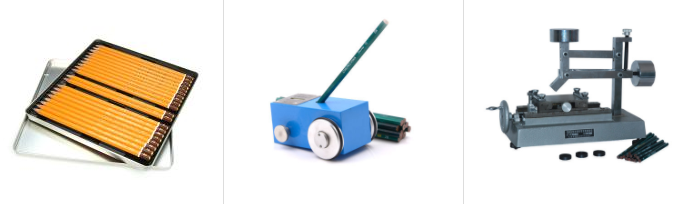

According to the determination of the standard paint film hardness, there are two methods: pendulum Hardness Tester and pencil Hardness Tester.

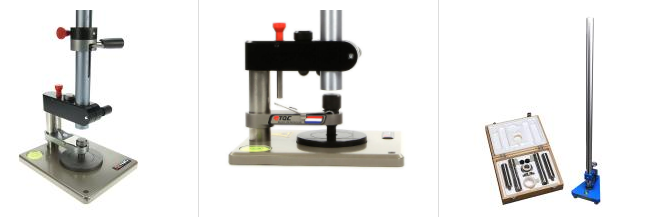

The basic principle of pendulum hardness testing method is: through the two steel balls embedded under the pendulum touch the coating film sample, that is to say, the pendulum is placed on the coating film to be tested and swings. At this time, the steel ball presses the paint film. If the hardness of the paint film is high during a certain period of swing, the steel ball will be pressed in shallowly, which means point contact and less friction, and the swing attenuation time will be longer. The decay time is short. When measuring, first measure the time of glass swing attenuation (with an amplitude of 5 ° to 2 °), and then measure the paint film. Since the hardness of the paint film generally does not exceed the hardness of the glass, the time required for the former is less than the time required for the latter. The ratio of the two times is A small number to represent the hardness of the paint film, for example, the harder paint film is above 0.8, and the softer paint film is 0.2 to 0.3.

Pencil hardness belongs to the scratch hardness method, that is, the method of marking or scratching the paint film with a hard object (pencil) on the surface of the paint film is used to measure the hardness of the paint film. The pencil hardness method has two methods: manual operation and instrument test. It uses a pencil with a known hardness of the paint film to measure the hardness of the coating film. A pencil of first grade hardness (instrumental test) is used as the hardness of the coating film.

3. Flexibility (flexibitity)

The ability of a paint film to deform with its substrate without damage.

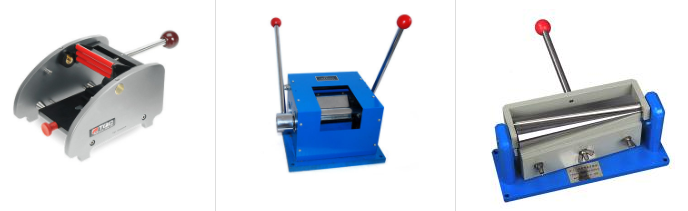

To meet the needs of different deformations (shock, vibration, cold and heat, expansion and contraction). The national standard stipulates that the testing method for the flexibility of the paint film is: expressed by the minimum shaft diameter on the flexibility Tester that does not cause the paint film to bend and crack. Coatings with good flexibility are generally

1 ~ 3mm.

4. 耐液性

漆膜的耐液性是指漆膜接触各种液体(水、溶剂、饮料、酸、碱盐以及其它化学药品等)时的稳定性,其中包括耐水性、耐酸性、耐碱性、耐溶剂性 etc.。耐液性差的涂料,当其漆膜接触液体时可能出现失光、变色、鼓泡、起皱、变白、印痕等,耐液性好则应无任何变化或变化轻微。

各种木制品在使用中均有接触各种液体的机会,因而要求漆膜应有良好的耐液性。According to国标《家具漆膜耐液性测定法》规定,用浸透各种试液(该标准规定了氯化钠、碳酸钠、乙酸、乙醇、洗涤剂、酱油、蓝黑墨水、红墨水、碘酒、花露水、茶水、咖啡、甜炼乳、大豆油、蒸馏水等 15 种液体)的滤纸放在试样表面,经规定时间移去,According to漆膜的损伤程度评级。

5. 耐热性

漆膜的耐热性是指漆膜抵抗热量的能力。耐热性差的漆膜遇热可能出现变色、失光、印痕、鼓泡、起皱、开裂等现象。各类木制品遇热的机会并不多,但是台面类家具(如餐桌、茶几、厨房案台、实验台、写字台等)表面上经常放热茶杯;厨房家具表面可能接触热水、蒸汽与热油,这类木制品的漆膜要有较高的耐热性。

漆膜的耐热性分耐干热和耐湿热两种情况,后者对漆膜性能要求更高,检测漆膜耐热性能时应分耐干热和耐湿热两种方法。

According to《家具表面漆膜耐干热和耐湿热测定法》两个国家标准规定,检测漆膜干热时用一铜试杯,加热至规定温度置于被测样板上,经规定时间后移走,检验漆膜状态与光泽变化情况评级。检验漆膜耐湿热性能在铜试杯下放一块湿布即可。

6. 耐磨性 ( abrasion resistance)

耐磨性表示 漆膜对摩擦作用的抵抗能力。 某些木制品对其表面漆膜的耐磨性要求很高,如写字台面、椅座面、地板等。一般说来硬漆膜的耐磨性高。

According to《家具表面漆膜耐磨性测定法》国标采用漆膜磨耗仪测定漆膜的耐磨性,该仪器有一回转圆盘,待测漆膜样板放在圆盘上,圆盘以 70 ~ 75r/min 的速度回转,在漆膜上放一橡胶砂轮,砂轮负载 1000g

的砝码,在具一定负载砂轮的研磨下,耐磨性高的漆膜可能研磨几千转甚至几万转后均不露白也未研磨掉漆膜,反之,耐磨性差的漆膜可能研磨几百转便已露白并磨掉(失重)许多漆膜,故漆膜的耐磨性是以一定负载下不露白的研磨转数或漆膜在规定转数(一般 100 转)下的失重克数表示,并以此来评定漆膜耐磨性等级。

7. 耐温变性

耐温变也称耐冷热温差变化性能,耐冷热温差性是指漆膜抵抗温度由低到高或由高到低这种温度变化而造成漆膜破坏的能力。木制品有时会经受温度激烈的变化,如在我国北方冬季时,室内外温度差异较大。漆膜耐温变性好,则漆膜会完好无损,否则也可能产生失光、变色、鼓泡与开裂等缺陷。

According to《家具表面漆膜耐冷热温差测定法》国家标准规定,检测耐温变性时,要将涂漆干透的样板连续放入高温( 40 ℃)恒温恒湿箱与低温(- 20 ℃)冰箱,观察漆膜变化,以不发生损坏变化的周期数(从高温到低温)表示。

8. 耐冲击性

漆膜耐冲击性又称抗冲击性强度,是指涂于基材上的涂膜在经受高速重力作用下可能发生变形但漆膜不出现开裂与脱落的能力,它反应了被测漆膜的柔韧性和对基材的附着力。常用冲击试验仪见检测,图

1 — 5 ( d )。用一定质量的重锤落在漆膜样板上,使涂膜经受伸长变形而不引起破坏的最大高度,用重锤质量与高度的乘积表示涂膜的耐冲击性能,通常用 N.cm 表示。

7. 漆膜光泽

物体表面被光照射时,光线朝一定方向反射的性能即为光泽。漆膜光泽是其外观质量的重要指标之一,关系到漆膜的使用性能,常用光泽度测定仪检测,当漆膜出现微缝、下陷和老化时,就开始失去光泽。影响漆膜光泽的因素很多,主要有涂料品种与性能、基材性质、涂饰方法、涂饰工艺等。

Paint can be divided into gloss paint and matte paint according to its gloss. Glossy paint and matte paint have different film luster, even if it is bright paint, due to different types of paint, the leveling of the paint is different, and its paint film gloss is also different. When brightly decorated, the surface of the substrate should be flat and smooth. If the surface is rough, the incident light cannot be concentrated and reflected in one direction, and people feel that the surface is not bright. The gloss of the paint film is also different depending on the finishing method. Generally, the paint film of spraying or curtain coating has higher gloss than the paint film of brushing. When finishing by hand, wipe-on varnishes work better than brushing. The gloss of the paint film is related to the finishing process. The thickness of the coating, the quality of hole filling, the modification and grinding of the intermediate coating and the surface paint film, etc., will all make the paint film show different gloss. At present, CHINA's furniture enterprises are divided according to the following principles: the glossiness of glossy varieties is above 70%, among the matt varieties: the glossiness of semi-matt varieties is 30% to 70%, and the glossiness of full matt varieties is 10% to 20 % % .