The handling and preparation of fluids is part of the entire coating product manufacturing process. part. It includes various unit operations before the coating process, such as pumping, filtering, degassing, cooling, temperature control, etc.

The purpose of any coating is to produce a liquid film of uniform thickness. Coating L Cheng Shuai is very concerned about the uniformity and uniformity of the liquid film J 20 degrees, and does not indicate to most users. For photographic products, regular customers' comprehensive evaluation of uniformity includes the uniformity of brightness and optical density. According to Lambert's law, for transparent materials, the density D is proportional to the thickness and absorption coefficient  .

.

D = 0.43343h (x,z,t) K[c (x,y,z,t)]

where D-optical density

K = K[c, (x,t)]

h = h(x,t)

C = C(x,t)

K——absorption coefficient m, according to Beer's law

h - film thickness

c - the concentration of the solution

t——time, s

x——space coordinate vector

[x,y,z], m

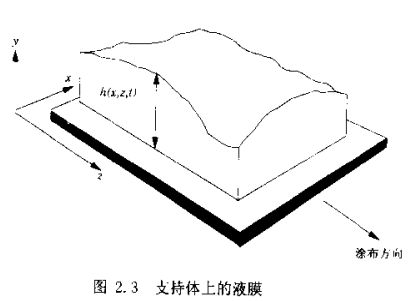

For aqueous solutions, the absorption coefficient and concentration are linearly related (Beer's law), and the concentration itself also depends on time and the spatial coordinate characteristics x= (x,y,z) of the system under consideration. As shown in Figure 2.3, the thickness is also a function of time and space coordinate properties x = (x,z).

In predetermined metering, a film is formed at the coating nozzle. The liquid enters the coating nozzle from the feeding camp (even one side or the center), and is distributed to the entire coating width through the distribution chamber. . 4). The quantitative gap can be regarded as the last unit in the conveying system. Therefore, it plays a decisive role in determining the uniformity of the liquid film.

The quantitative gap of the liquid passing through the extrusion nozzle can be expressed by the relationship between flow velocity and pressure drop. For a Newtonian fluid with one-dimensional flow, it can be expressed by the following formula:

In addition, according to the conservation of mass, the relationship between the flow rate of the liquid film thickness spoon and the coating speed is shown in the formula:

In the formula, △P =??p (x, t)??△p——repulsive force drop through the gap, N/m2

L=L(x) L——gap length, m

T= T(x,t) T——temperature, K

w = w(x) w——gap height, m

μ=μ[c (x,t)T(x,t)] μ——viscosity, Pa·s

q=q(x,t) q——volume flow/unit

U=U(t) U——coating speed, m/s

As expressed above, is ultimately a function of space and time. This fact is important because becoming a dependency on the primary parameters has a decisive significance for the rate of change of the process involving the most important parameters.

The result dD/D of the optical density change can be guided by formula (2.2) and (2,3) inserted into formula (2.I), and the derivatives of x and t can be obtained as follows:

Equation (2.4) is the overall mathematical model of the uniformity of the coated product. From this, various basic factors that affect uniformity can be derived.

Item (1) in the formula - the change of absorption coefficient due to the change of concentration

Item (2)——Pressure drop along the quantitative gap direction

Item (3)—Change of gap height

Item (4)—Change in Gap Length

Item (5)——Viscosity changes due to changes in solution concentration

Item (6)—the viscosity change caused by the temperature change of the solution

Item (7)—change of coating speed

If these effects themselves can be modeled concretely. Only then can we quantify their size and identify means of eliminating and reducing their impact.

Partial derivatives are properties of the material and should be known for all coating solutions. They are easy to measure in the laboratory and usually have non-zero values. For example, ou!oT represents the viscosity-temperature coefficient, that is, the dependence of viscosity on temperature, while △x and △t are the fluctuations of process parameters in space and time, respectively. Through equipment design and process control, fluctuations can be limited within specific limits, and the uniformity of coating can be maintained within a certain range. For example, oT/ax describes the temperature change of the coating liquid flowing from the inlet of the cavity to the end of the cavity along the x coordinate. This value will not be zero, because the temperature of the coating liquid entering the coating nozzle is different from the temperature of the coating nozzle. The cloth nozzle acts as a heat exchanger. Because fluid viscosity is temperature dependent, temperature will affect coating uniformity.

In formula (2.4), term (2) Δp/x represents the pressure drop along the direction of the equalizing gap. If the pressure drop in the direction of the gap is taken, Ap becomes the pressure distribution of the mouth cavity, so oApA moves; usually it is not zero. A typical extrusion nozzle or weir plate design goal is to accurately calculate Δp. Balance the pressure drop by varying the height (item 3) or length (item 4) of the gap.