Air spraying uses the pressure of compressed air to force the paint out of the tank. A type of coating method in which the paint liquid is atomized into uniform fine particles through the nozzle of the Spray Gun, and dispersed and deposited on the surface of the object. It is also the most widely used type of coating method for painters.

Advantages of Air Spray

1. The surface of the coating film is uniform, with good smoothness, excellent coating film and high decoration (compared with manual coating ).

2. It has a good coating effect on products with complex structures and shapes, irregular workpieces, object surfaces with gaps and small holes, inclined or uneven objects, and large objects.

3. High production efficiency, strong adaptability, and wide application range. Compared with manual brushing, it has the characteristics of labor-saving, time-saving, and labor-saving.

4. Effective and satisfactory coating effect for quick-drying and volatile paints such as nitro paint and perchlorethylene paint.

5. For amino acid Hongqian paint, etc., Hongqian paint can obtain better paint film quality with fullness.

Disadvantages of Air Spray

1. The waste of spraying is large. About 10% of the paint mist will be wasted with the diffusion of air during the spraying process .

2. The paint used for spraying needs to be diluted with a certain amount of thinner. For example, when spraying nitro paint, it is usually necessary to use a thinner that is 1 times the capacity of the paint for thinning, so the amount of solvent used is large.

3. The thickness of the paint film sprayed at one time is limited, such as spraying nitro paint, it usually takes 3-5 or 4-5 consecutive coats to obtain a thicker paint film.

4. During the construction, the flying of paint mist and the volatilization of solvents seriously pollute the environment and have certain harm to the human body. Therefore, the construction should be carried out in a special spray booth, and the operators must wear gas masks to prevent poisoning.

5. If the ventilation is poor during construction, it may cause fire or even explosion when the mist is too thick, and safety facilities need to be strengthened.

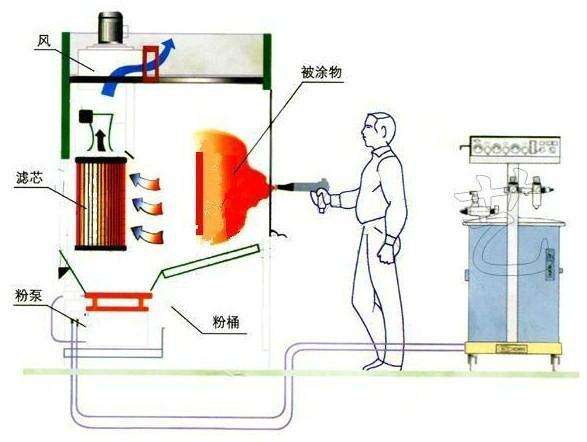

Air Spray Tool Equipment

Spray gun: The paint is atomized and sprayed onto the surface to be coated by means of compressed air.

Paint storage tank or pressure paint supply cylinder: the main function is to supply paint to the Spray Gun, such as the Spray Gun with its own paint storage tank (paint pot) for spraying and supplying paint for a small amount of products; the pressure paint supply cylinder (or tank) is mainly used for batch workpieces Or spray paint for finished products, usually each can can be filled with about 50kg of paint, which can be used for large-area continuous spray paint supply.

Air Compressor: Generate compressed air for spraying.

Oil-water separator: filter the moisture and oil in the compressed air. The compressed air generated by the compressor is filtered by the oil-water separator to obtain clean compressed air for the Spray Gun. In this way, when spraying, it can prevent the moisture or oil in the air from mixing into the paint film to cause defects such as pinholes, air bubbles or poor adhesion of the paint film.

Rubber hose: It is used to connect air transmission, such as connecting Air Compressor, oil-water separator and Spray Gun.

Spray booth: for spraying construction.

Exhaust system (that is, the exhaust air supply device): the air supply system needs a filter, and the exhaust system ventilates the operation room to maintain a certain wind pressure in the operation room to prevent the residual gas mist from polluting the environment and damaging health.