Coating paper with one or more layers of coating can significantly improve its whiteness, opacity, smoothness, gloss, printability and other surface properties.

The physical mechanisms involved in the paper coating process are often very complex. For example, in drawdown blade coating, the coated pigment particles may transition from one extreme (i.e., near zero shear rate far from the blade tip) to the other extreme (i.e., The shear rate is very high near the tip region). Coating pigments with different microparticle compositions can have complex rheology, such as shear thinning at moderate shear rates and thickening (ie thickening) at high shear rates. Blade deflection and base paper deformability and porosity constitute complex coating fluid boundary conditions.

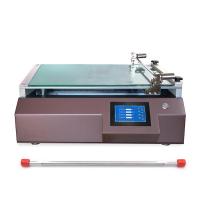

In addition, there is a dynamic boundary (contact) line between solids, liquids, and air, which leads to unresolvable and abnormal stress-strain problems under the traditional no-slip boundary conditions (that is, stress in the solid-liquid-gas dynamic contact line processing theory can become infinite). Therefore, any existing computer model cannot completely simulate the above-mentioned problems. The experimental coating machine AT-TB-2 can coat coatings in different states. At the same time, the coating thickness can be adjusted, the coating pressure can be adjusted, and the bottom plate can be heated to provide different temperatures. He can provide coating operating conditions at will. The basic information is considered to be the main tool that can avoid these theoretical difficulties and solve practical coating problems.