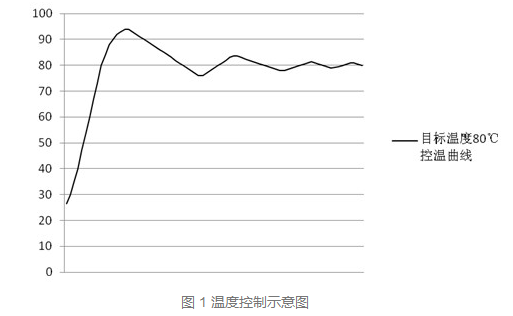

Heated magnetic stirrers are mainly used in the fields of chemical synthesis, analytical chemistry and life sciences. For the heating function, customers often pay more attention to the heating speed, the ability to control temperature overshoot and maintain temperature stability, but the heating speed and control temperature overshoot are an irreconcilable contradiction, especially for different media in an open environment , The application of different volumes makes it even more difficult to balance the contradictions. In order to be able to meet the needs of more customers in different applications, manufacturers of such products around the world have adopted a similar compromise control method --- allowing a certain degree of temperature overshoot when the target temperature is reached for the first time, and then Any large temperature overshoot is no longer allowed, and only a very small oscillation near the target temperature is formed as soon as possible (as shown in Figure 1), which inevitably leads to the simultaneous pursuit of heating speed and temperature overshoot for this type of product. , not up to a very good standard.

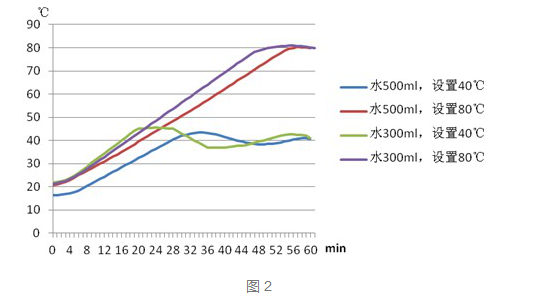

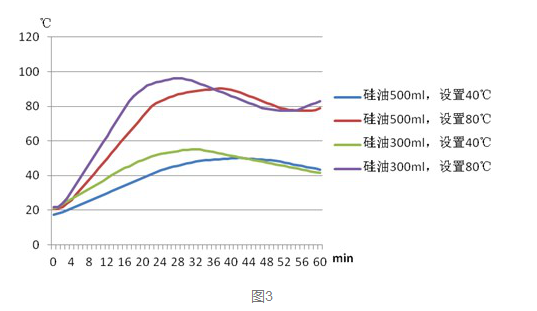

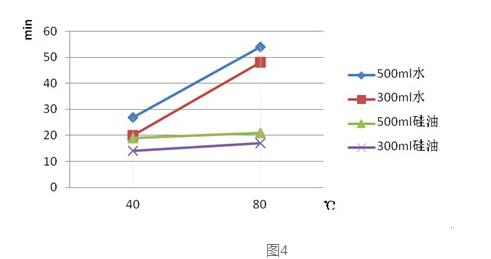

For such products of Dalong Instruments, we used water and silicone oil as the heated medium respectively, and conducted heating experiments under the same temperature conditions. The experimental results are shown in Figure 2-4.

It can be seen from the experimental results that:

Compared with water, under the same experimental conditions, using silicone oil as the heated medium takes a shorter time to reach the target temperature, and the overshoot temperature is larger, because the specific heat capacity of water (4.2 x 103 J/Kg) is greater than that of silicone oil (At 20°C, the specific heat capacity of silicone oil is 2.49 x 103 J/Kg). Under the condition of absorbing the same amount of heat, the material with smaller specific heat capacity will dissipate heat slowly, and the temperature rises faster and the temperature rise is larger.

When the target temperature is set at 40°C and 80°C respectively, the time difference required to reach the target temperature is small when using silicone oil as the heating medium, while the time difference required to reach the target temperature is relatively large when using water as the heating medium, because as the temperature increases, The specific heat capacity of silicone oil will also decrease. When the temperature reaches 100°C, the specific heat capacity of silicone oil will decrease to 1.63 x 103 J/Kg), while the specific heat capacity of water will remain basically unchanged. quick.

Under the same experimental conditions, two volumes of water and two volumes of silicone oil were used as the heating medium. The smaller the volume, the shorter the time required to reach the target temperature and the greater the temperature overshoot.

In general, the ambient temperature, the surface area/volume of the container, the specific heat capacity of the heated medium, the size of the indoor airflow, the temperature difference between the target temperature and the external environment, etc. will all have an impact on the heating rate, control temperature overshoot and maintain temperature stability. Therefore, for some studies The personnel are strictly required to control the first temperature overshoot. It is suggested that the user can use the following two methods in the application:

(1) Place the sample after the temperature of the heated medium is stable;

(2) Set the heating temperature to about 10°C lower than the target temperature. After the temperature stabilizes, gradually adjust the set temperature to the desired target temperature value.

For another part of researchers who require to reach the target temperature quickly, regardless of the first temperature overshoot, it is recommended that users use two other methods in the application:

(1) Take some heat preservation measures during the heating process, such as adding a cover;

(2) Set the set temperature value higher than the target value, and when the heated medium is close to the target temperature, reduce the set temperature to the target value.

In addition, in order to achieve a good heat transfer effect, it is recommended that users:

(1) Try to use a container with a size similar to that of the instrument panel;

(2) Try to ensure that the bottom surface of the container is completely attached to the surface of the Heating Plate.