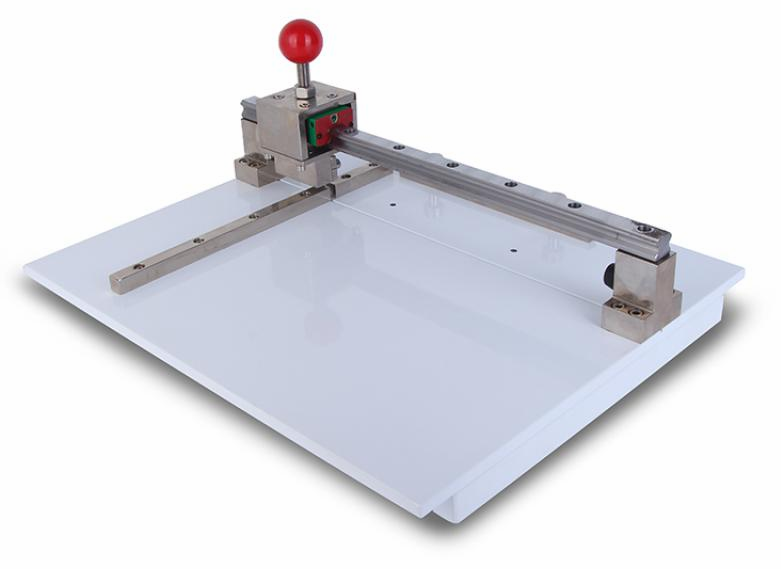

YT- BY25 edge pressure sampler is a special sampling device required for corrugated cardboard edge pressure test and adhesive strength test. It can quickly and accurately cut samples of specified size. It is a satisfactory auxiliary Tester for inspection and other departments.

The specific operation method of YT- BY25 side pressure sampler is as follows:

1. Sampling

1.1 According to the type of sample taken (edge pressure sample or bonded sample), determine the length of the sample to be cut, select the position of the pin hole and position the adjustable positioning block with the pin. There are three sets of pin holes in the sampler from outside to inside, and the corresponding sampling size of each pin hole is as follows:

1) The first group: cut the sample length of 100mm (edge pressure sample), the cut surface is perpendicular to the direction of corrugation.

2) The second group: cut the sample length 100mm (adhesive sample), the cut surface is perpendicular to the corrugated direction;

3) The third group: cut the sample with a width of 25mm, and the cut surface is parallel to the direction of corrugation;

1.2 Pull the handle ball to the position to be cut.

1.3 Use a utility knife to cut a sample with a size of about 240mm×240mm; lightly press the sample with the left hand, push the handle ball hard with the right hand, and cut out a reference side along the corrugation, which is called the first reference side.

1.4 Place the first reference side close to the inner side of the fixed positioning block, and cut out another side perpendicular to it, which is called the second reference side.

1.5 Put the second datum side close to the inner side of the fixed positioning block, and the first datum side close to the inner side of the adjustable positioning block, and cut out a sample length of 80mm or 100mm.

1.6 Fix the adjustable positioning block in the third group (from the outside to the inside) of the pin holes, put the side of the first reference side (that is, perpendicular to the corrugated direction) close to the inner side of the fixed positioning block, and the side perpendicular to it is close to the adjustable Inside the positioning block, cut out a sample width of 25 mm.

2. Matters needing attention

2.1 It is strictly forbidden to put your hands in the position where the sample is cut to prevent cuts.

2.2 After each sample cutting, the handle ball should be pulled back to the position to be cut.

2.3 The direction of the incision needs to be parallel or perpendicular to the direction of the corrugation, and the sample should not be loose during the process of cutting the sample.

2.4 If the incision of the sample is seriously curled or skewed (one of the two edges formed by the incision surface, the surface, and the inner paper is projected onto the surface where the other edge is located, and the distance between the projection line and the edge exceeds 0.3 mm), the blade should be replaced. The replacement method is: loosen the compression screw on the knife holder, remove the old blade, replace it with a new blade, adjust the position of the blade so that the angle between the blade edge and the base table (the opening of the angle faces the direction of the fixed positioning block) is about 45° and Tighten the screws.

3. Maintenance

1) Keep the sampler clean, and use a soft cloth to remove surface dust and paper scraps after use.

2) A small amount of lubricating oil should be added frequently to the guide part.

3) When not in use for a long time, anti-rust oil should be applied to the blade, guide shaft, etc., and a cover should be added to prevent dust.