1. Overview and safety precautions:

SG-1 Drying Tester is designed according to the international standard of ISO 9117-1:2009 Paints and Varnishes - Drying Test - Part 1: Determination of Hard Drying State and Hard Drying Time. Whether the coating system paint, varnish or similar material reaches the hard-dry state after the specified drying period can also be used to determine the time required to reach the hard-dry state. The hard-dried state here refers to the state in which the entire thickness of the coating is completely dry from the outside to the inside, which is different from the surface-dry state. The surface dry state refers to the state where the surface of the coating has dried but the interior is still mostly wet and soft. The hard drying time refers to the time elapsed from the completion of the coating preparation until it reaches the hard drying state.

ISO 9117 Paints and varnishes - International standard for drying tests is divided into three parts:

Part 1: Determination of hard working state and hard working time;

Part 2: Palletizing test;

Part 3: Determination of surface dryness (small glass bead method).

Part 2 of this standard is to replace the ISO 4622:1992 international standard (the corresponding national standard is GB/T 9280-2008). Part 3 of this standard is to replace the ISO 1517:1973 international standard (the corresponding national standard is GB 6753.2-86). Part 1 of this standard has no corresponding national standard yet. Hardness Testers can also be used for stackability testing (ie part 2 of this international standard).

For the consumables used in Part 1 of ISO 9117, flat round rubber pads and screen cloth, please refer to ISO 3678 Paints and varnishes - non-marking test international standard (the corresponding national standard is GB 9273-88). The ISO 9117 international standard stipulates that the diameter of the flat and round rubber pad is (22±1) mm, the thickness is (5±0.5) mm, and the hardness is (50±5) IRHD; the wire mesh cloth is nylon monofilament woven wire mesh, and the minimum size is 100mm ×100mm, the mesh diameter is 0.12mm, and the mesh hole is approximately 0.2mm. The dry Tester can also be used for non-marking tests at higher loads.

The dry Tester is used in the testing process of chemical raw materials. Users should establish appropriate safety and health protection measures and determine rules and regulations according to relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are not within the scope of this manual.

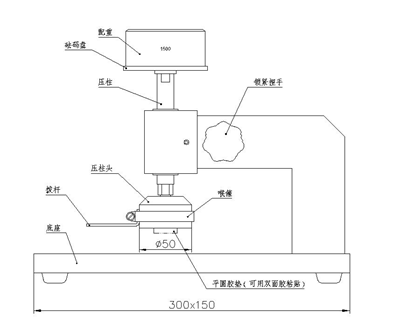

2. Main technical parameters:

1. The diameter of the bottom surface of the pressure column head:50mm

2. The total mass of the pressure column components:250g±5g

3. 1500 counterweight accessories:1250g±5g (actual mass)

4. Dimensions of the instrument:300×150×160mm

The pressure column head of the dry Tester can swing to ensure close contact with the surface of the test plate. In addition to moving up and down flexibly to pressurize the surface of the test plate, the pressure column assembly can also rotate 360 degrees to replace the wire mesh cloth.

3. Test principle:

Prepare the coating on the substrate and dry it under the specified conditions. Press the loaded wire mesh cloth to the specified area of the coating and twist it 90 degrees. Visually inspect the coating to determine whether the coating has reached a solid dry state.

4. Operation steps and precautions:

1. Loosen the locking knob to turn the pressure column head upwards and lock it with the locking knob. Place the flat round rubber pad in the middle of the pressure column head (can be fixed with double-sided tape), cover the flat round rubber pad with silk mesh, and fix it to the pressure column head with a throat hoop (fix the lever at the same time). Make sure that the underside of the screen cloth is wrinkle-free. Use a new screen cloth for each test. Then loosen the locking knob to turn the pressure column head down and lock it with the locking knob.

2. Put the counterweight (the standard stipulates that the total pressurized mass is 1500g) on the weight plate and lift the pressure column assembly by hand, put the test plate on the base, and gently put down the pressure column head to make the screen cloth and the test Test plate contact. Start the stopwatch (the precision of the stopwatch is 0.1s according to the standard), pressurize and count (10±1)s.

3. After the pressurization timer is reached, use the lever to turn the pressure column head to 90 degrees in about 2 seconds. Immediately thereafter lift the pressure column assembly, remove the test panel, and inspect it visually.

4. Do a total of 3 tests. If there is no trace or sticky mesh on the surface of the test panel for 3 times, it is judged as "hard dry", and if there are visible traces or sticky mesh for 1 or more times, it is judged as "not hard dry".

5. This test method is not applicable to some coatings that always leave marks or never leave marks regardless of whether they are dry or hardened. In addition, a careful distinction must be made between cohesive failure of the coating and peeling from the substrate, not to be confused with the above visible signs.

6. After each work is completed, the cleaning and maintenance of the instrument should be done in time.

7. If different pressurized masses are required, weights of appropriate quality (commercially available standard weights) can be added to the weight plate.

8. The flat round rubber pad and screen cloth are consumables, which should be prepared by the user.