Instructions:

1. This machine is used with the scraper Fineness Meter, and the operation of the scraper Fineness Meter itself will not be repeated here. The scraper Fineness Meter is not provided with the machine, please order it separately. Turn on the power, turn on the power switch on the "operation panel", and you can use the machine.

2. The terminal of the scraper stroke of this machine is fixed, and the starting position of the scraper stroke is adjustable within the maximum stroke range. According to the scraper specifications produced by our company, the machine presets the second gear start position. The "short board" file is suitable for national standard coating fineness boards and ASTM standard specification fineness boards, and the "long board" file is suitable for national standard ink fineness boards. When the "scraper mounting frame" is at the terminal position, select the "reverse" gear, and the scraper frame will move backward and stop at the set position according to the selection of "short board" and "long board". If you use a non-standard scraper and think that the set position is inappropriate, you can select the "long board" gear before backing up, and then manually determine the stop position of the scraper frame through the "stop" gear of the rotary switch during the backing process.

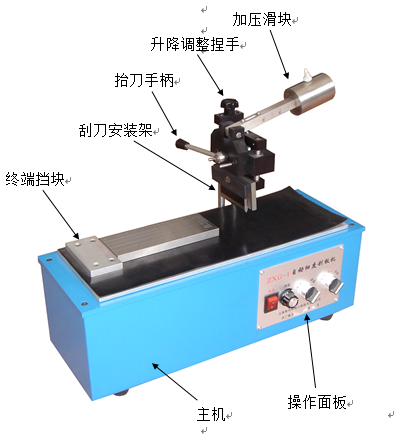

3. Before the operation of the scraper, put the "0" scale end of the fineness plate against the "terminal block", and place the scraper on the magnetic "scraper mounting frame". The "squeegee mounting frame" is suitable for the scraper produced by our company and the scraper of ASTM standard specification. The "Pressure slider" is used to adjust the blade pressure. The pressure of the scraper is determined by the viscosity of the sample: if the pressure is too high, the service life of the scraper and scraper will be affected; if the pressure is too small, the scraped sample will be unclear, which will be unfavorable for evaluation. After installing the scraper, scraper and pressurized slider, turn the "knife lifting handle" backward to lift the scraper, and turn the "lifting adjustment knob" to raise the "scraper mounting frame" until the scraper moves forward without touching the scraper. plate (you can use your other hand to slightly lift the "pressurized slider" when turning so that the knob does not feel too tight when turning). Turn the knob to the "scraper" position, the scraper frame advances and stops at the end of the stroke. Turn the "knife lifting handle" forward to lower the scraper, adjust the "lifting adjustment knob" so that the scraper touches the scraper and the horizontal bubble on the pressure rod is roughly centered, and tighten the supporting screw. Then turn the "knife lifting handle" back again to make the scraper leave the scraper, and complete the adjustment before use.

4. Before adding samples to the scraper, you can advance the scraper holder to the terminal (turn the knob to the "scraper" position), which is more convenient to add samples. According to the specification of the scraper used, select the "short board" or "long board" gear. After adding the sample, turn the knob to the "reverse" position, and the scraper holder will return to the initial position. Turn the "knife lifting handle" forward to press the scraper against the scraper, and turn the knob to the "scraper" position to complete the scraper movement.

5. After the scraper frame stops, turn the "knife lifting handle" to lift up the scraper, and the dispersion fineness can be visually judged (you can also move the scraper frame back and then visually judge). After the judgment is completed, the cleaning work can be done for the next operation.

6. The speed of the scraper can be adjusted with the "speed adjustment" knob. The "scraper/reverse" knob switch is used for the forward and reset of the scraper frame: select the "scraper" position, no matter where the scraper frame stops, it will move to the end of the stroke. Select the "reverse" gear, the movement of the scraper frame depends on the position of the "short board/stop/long board" knob switch: select the "short board" or "long board" file, the scraper frame will stop at the set position; Before backing to the set position, turn the knob to the "stop" position, and the scraper frame will stop at the current position.

Precautions:

1. Please use the machine under laboratory temperature and humidity conditions.

2. The motor of this machine has an electronic brake circuit. If it is not necessary, please do not make a momentary scraper-reverse conversion movement, so as to maintain the service life of the electrical components.

3. After use, please remove the "pressurized slider" or place a cork or other object under the "scraper mounting frame" to reduce the lateral force of the lifting slider of the scraper frame.

4. After using the machine, please clean it in time. After using for a certain period of time, please lubricate the moving guide rail in due course (from the opening at the back or remove the upper cover).

5. When starting the machine for the first time at a low temperature, the thickening of the lubricating oil in the reducer will affect the running speed of the motor. You can choose the "long plate" gear, and do a few more reciprocating movements to stir the lubricating oil and thin it out, until the motor speed is normal before starting to work.