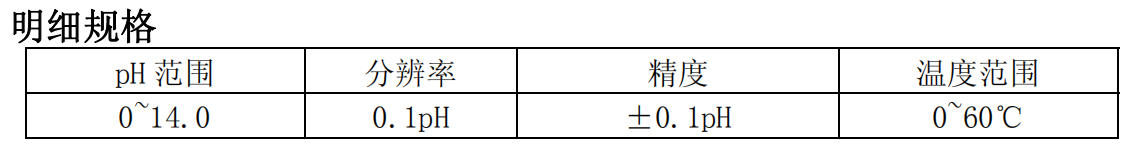

pH Pen Instructions

1. Remove the black protective cap, flip the switch on the top to turn on the pH pen. (If the pH bulb is dry, it needs to be activated , otherwise there will be a large error)

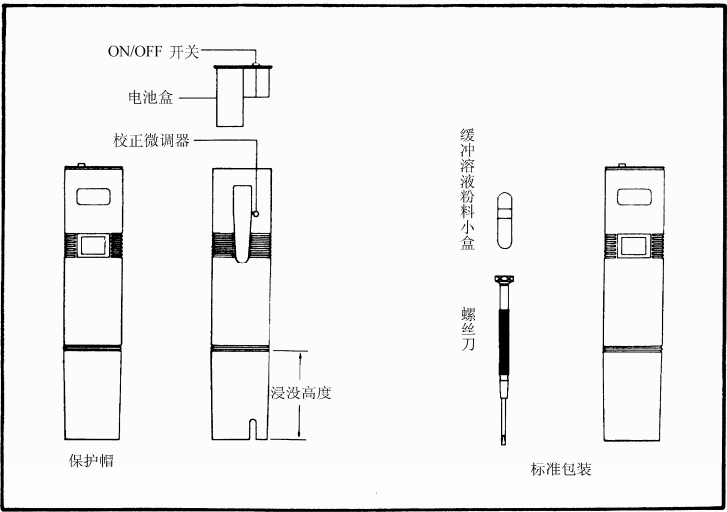

2. Calibration in standard buffer solution. Note: Whether it is calibration or testing process, the liquid level of the liquid to be tested must not exceed the warning line of the pH pen. (As shown below)

Activation of the pH pen

Soak the pH pen in pH4.00 buffer solution or 3M KCL solution for 12 hours. Confirm that the pen tip is immersed in at least 1 inch, but must not exceed the warning line, that is, the immersion height.

Calibration of pH pens

Put the activated pH pen in the buffer solution of pH6.86, and turn the zero point correction potentiometer on the back of the pH pen to display the pH value of the buffer solution. Then clean the pen, put it in the buffer solution of pH4.00, and turn the slope correction potentiometer on the back to display the pH value of the buffer solution. (Note: The rotation angle range of the correction potentiometer is 0~180 degrees, do not rotate it hard to avoid damage.)

Preparation of pH6.86/4.00 buffer solution

Remove buffer solution powder from package to container. Add 250ml distilled water. Stir until the solids are completely dissolved.

application

Swimming pools, factory wastewater, food processing, schools and laboratories, fish farming.

Other pen watch series

1. Model 650 ORP test meter.

2. Type 110, 111, 112, and 115 conductivity test pens, with a range of 10~1990μS, 0.1~19.9mS, 1~199 μS, 0.1~99.9μS; Type 113 TDS test pen with a range of 10~1990ppm.

3. Model 720C is a temperature testing pen with a range of -160~850°C.

quality assurance

The warranty period of this machine is one year (according to the date of purchase, the test electrode part is not covered by the warranty). If there is a quality problem during the warranty period , the company will repair or replace the parts free of charge; if the failure or damage is caused by human factors, Our company wholeheartedly repairs it on our behalf, but we need to charge the cost of materials. When returning the machine to our company, please wrap it properly with packing materials to avoid damage during transportation. In any case, please contact the company before returning the machine and get the approval of the company, and the machine can be returned.