The manufacturer's Product Data Sheet (PDS) should always be consulted when suggesting a coating or coating system for a specification or in charge of coating application. PDSs generally contain information on appropriate use and environment, performance characteristics and application information, including mixing, application methods and equipment, and suggested thickness ranges for materials. The information provided by the manufacturer should be followed as closely as possible to maximize the performance of the coating material. In this article, we will investigate the possible failure mechanisms of the coating when the coating thickness is insufficient or excessive.

Coating materials are selected to take into account the target application thickness. The range suggested by the manufacturer and the thickness indicated in the project specification should be consistent. If discrepancies exist, the specifier and paint manufacturer should be contacted for resolution. When applied at the proper thickness, the physical and protective properties of the coating material are optimized. Coating performance problems often arise when insufficient attention is paid to the applied thickness of the material and the finished product has either insufficient or excessive coating thickness.

lack of coating thickness

Insufficient coating thickness can occur in a number of ways, but basically coating thickness is not specified or communicated correctly, coating is insufficient or the volume solids content of the coating is not accurately reported. The quality of a coating application should not be judged by coverage; i.e. looking good. While coatings have cosmetic advantages, the goal is often to protect the substrate from corrosion or other environmental factors. If the material is applied until complete coverage appears regardless of the thickness specified by the manufacturer, the resulting dry film thickness may be lower than the target thickness to obtain very good coating performance in a particular environment.

The importance of application within that range is magnified when the specified coating thickness range represents thinner coating films, such as 1.0-1.5 mils. If the coat weight is 0.5 mil, the film thickness is reduced by 32-50%. Special care is required when handling thin film applications to ensure proper thickness is obtained. In contrast, if a range of 20-30 mils is specified and the actual film thickness is 19 mils, a 5% reduction in coating thickness may not manifest as a significant problem in coating material performance.

Several problems arise when coating films are spread significantly below the recommended thickness range:

Substrate Visibility

When proper coverage is not achieved, the substrate or underlying coating can be seen through the coating material. While this is not a desirable aesthetic condition, it can also make the underlying coating material or substrate susceptible to corrosion, degradation from exposure to solar radiation (sunlight) or other environmental influences. For example, if a polyurethane topcoat is applied over an epoxy coating and there are several deficient areas, the epoxy coating is more prone to chalking due to inadvertent exposure to UV light. Results include spotty color and sheen, uneven erosion patterns, and possibly a shorter period of maintenance painting.

(Photo 1) - Wood siding has poor coating coverage. The base is visible through thin coat application.

precise rust

Precision rusting can occur when the film does not provide an adequate barrier or cathodic protection to the underlying metal substrate. For example, any primer, including a zinc-rich primer applied to a blast-cleaned steel surface, where the depth of the surface profile is greater than the thickness of the coating, will not adequately cover the tip of the anchor profile peak (particularly the rouge peak) on the tip of the steel, and will likely Little or no protection and may stick to the coating. Failure to stir zinc-rich paint during construction can exacerbate the problem by not providing enough zinc material to effectively protect the steel from corrosion. Rust will occur at the least protected points.

(Photo 2) - Precise rusting through topcoat.

Cracking/brittleness of the coating

When the coating film is applied below the target thickness range, the physical properties of the film itself may be compromised. For example, a modified polyurethane liner with inherently high cohesive strength at a thickness of 30 mils would be more brittle than expected based on a coating thickness of 5-8 mils. Reduced flexibility of the coating corresponds to reduced cohesive strength of the film and can lead to cracking or delamination.

(Photo 3) - The cracked top coat of the system should be applied approximately 20 mils below the minimum specified thickness range.

Correcting insufficient coating film thickness is not always the same as adding more, or making the next coat thicker. Inorganic zinc coatings generally have poor interlayer adhesion when applied in multiple layers. Corrosion inhibiting epoxy primers require consideration of drying and curing recoat intervals, loss of primer thickness is also a reduction in primer functionality - the next thicker coat may not make up. Surface coats may need to be scratched before additional coats are applied.

Clearly, owners do not want to deal with the consequences of poor film performance. Contractors certainly do not want to deal with correcting low film thicknesses. Two good arguments for achieving the desired minimum film thickness. The other side of the coin failed to stay below the maximum coating thickness. This also has consequences.

Excessive coating thickness

Causes of excessive coating thickness due to insufficient thickness are application dependent, but causes of application error are variable. Typically, applicators are unaware of the effects of excessive coating thickness on coating performance. Protective coatings are designed to perform within a specific thickness range based on the chemistry of the coating and the intended service. Therefore, using a protective coating more does not equate to better. In fact, several additional problems or failure modes were attributed to those described for over-thickness of the coating rather than under-thickness. Several consequences of excessive coating thickness are discussed below.

droop/run

If the coating material is applied in excess, the wet coating can run or sag on vertical surfaces. Coatings with lower viscosities are especially prone to sagging and running if applied too thickly. When the coating sags, we are left with an uneven film surface. Not only does this create too much film build-up in the sag area, but it can also lead to an insufficiently thick surface and the problems discussed above.

Photo 4 - Saggy coating on a vertical surface.

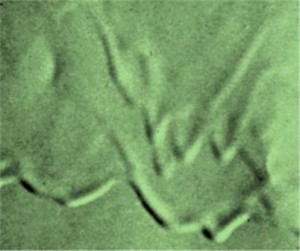

cracked / layered

Some coatings, such as epoxies, are prone to cracking and delamination when the coating thickness is higher than the manufacturer's recommended range. The high epoxide functionality of these resins cures after forming a highly crosslinked polymer network that exhibits high temperature and chemical resistance but low flexibility. The additional internal stresses associated with excess coating thickness often lead to cracking of the material, which may subsequently lead to delamination of the coating. Typically, delamination occurs at the weakest interface. When the coating is applied too thickly, the cohesive strength of the material is usually compromised. Cohesive failure in coatings applied too thickly is not uncommon for cross-linked coatings. in addition,

(Pic 5 above) - Too thick will cause stress cracking/cracking.

(Photo 6 right) - Cohesive cracking of the coating.

wrinkled

In the case of excessive coating thickness, the top surface of the coating may dry or cure before most of the coating. In these cases, the top surface forms a skin of static dry material over the flexible, soft uncured material, which causes the surface to deform as the material below moves. Ridges and valleys in the skin are seen as wrinkles. Alkyd coatings are especially susceptible to surface wrinkling when overcoated as they cure through atmospheric exposure to oxygen. The oxidation process occurs first at the surface and continues through the thickness of the coating, but at a much slower rate. Applying a film that is too thick creates a problem, leaving the majority of the film soft and uncured with less exposure to the atmosphere.

(Photo 7) - Apply wrinkle coat at four times the recommended thickness

increased drying time

(Photo 8) - Wash the surface. Dirt gets embedded in the top coat.

涂层的干燥时间和固化时间通常与涂层厚度直接相关。如果涂层涂得太厚,延迟干燥时间会影响重涂时间表,溶剂释放以及由于软表面异常延伸而引起的污垢和碎屑吸收。这可能导致涂覆不良的表面或不希望的外观。

固化不当

与起皱和增加干燥时间一样,过多的薄膜构造可能在固化期间引起问题。某些材料在投入使用之前可能无法完全固化,从而使涂层表面太软,容易损坏并且不适于维修。如果顶部表面固化而下面的材料不固化,也可能发生溶剂截留。由于较厚的薄膜产生较厚的,较低渗透性的屏障,因此任何夹带的溶剂或水分将更难以渗透通过系统。这种溶剂捕获可能导致涂层起泡。

(照片9) - 以透明涂层形式出现的水泡,涂层厚度是木材基材的三倍。

涂层厚度测量的方法

在良好的情况下,应在应用时检查涂层材料的湿膜厚度,以帮助确保满足规定的厚度范围。这可以在施加时使用湿膜厚度计来完成。如果怀疑干膜厚度不正确,可以使用几种技术或仪器来测量涂层系统的厚度。

Tooke Gage

Tooke量具可以在现场或实验室中使用。为了用该仪器确定膜厚度,使用基于预期厚度范围选择的成角度刀片将切口制成涂层直至基底。然后使用显微镜(眼睛)观察切口,并通过量具的视觉在视觉上明显。采用所选切割刀片的转换以及刻度读数将为每个可见涂层提供涂层厚度。ASTM D4132,“通过破坏性,横截面手段测量保护涂层系统的干膜厚度的标准实践”描述了使用这种类型仪器的程序。

限制- 这是一种破坏性测试。切割刀片将暴露一小部分基板。

无损涂层厚度计

非破坏性涂层厚度计可以在现场或实验室中使用。这些量具有黑色和有色金属两种型号可供选择,可以从各种金属中获得涂层厚度测量值。超声波测厚仪适用于混凝土或砖石表面的涂层。这些量具使用探针(即换能器)在施加到表面的耦合剂的帮助下将超声信号发送到涂层中。用于测量金属表面涂层的应变计使用涡流和/或磁感应技术。将测厚仪放置在涂覆表面上,并提供总涂层系统厚度的数字读数。ASTM D7091,“无损测量应用于黑色金属和非磁性的非磁性涂层干膜厚度的标准规范,

Limitations - Only total coating system thickness measurements can be obtained using this method; individual coatings cannot be measured when fully applied. Note that some ultrasonic Thickness Gauges can differentiate coatings but may not be able to measure the thickness of coatings with air-entrained voids or those containing glass flakes.

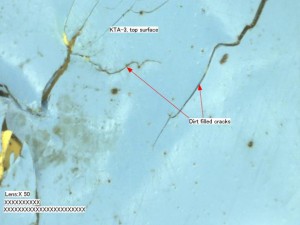

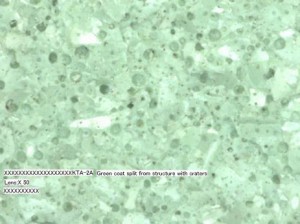

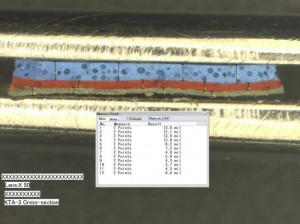

Microscope with scale

The cross-sectional thickness of the coating is mainly carried out in the laboratory, and the samples are collected from the field. Some microscopes have dimensions mounted on one of the spectacle lenses, similar to the Tooke gauge (described earlier). Digital microscopes often have measurement tools where two points are selected along with the current magnification to calculate the coating thickness, which can be expressed in mils, inches, microns, millimeters and other units. Photographs are usually obtained with a microscope.

(Photo 10) - Example of a thickness measurement obtained from a digital microscope

When viewing a cross-section of a sample, multiple layers can be measured through the microscope. The advantage of the cross-sectional view in the microscope is the magnified view of each coating. Splitting between or within coatings as well as voids or other objectionable properties within coatings can be observed.

Limitations - Microscopes are generally not suitable for field use. If the sample is not removed cleanly from the substrate, it is possible to observe an incomplete coating system.

in conclusion

There are a large number of coating performance deficiencies, defects and failure modes that can be related to insufficient or excessive coating thickness. This article provides eight common examples of coating problems related to coating thickness.

Applied coating thickness compared to specification requirements and/or manufacturer's recommendations is an important consideration when investigating coating performance issues. That is, if the material is used beyond the recommended thickness range, it is reasonable to conclude that the performance of the product has been affected to some extent and the effect should be assessed. Note, however, that during a coating failure investigation, an effective investigation of coating thickness may reveal insufficient and/or excessive coating thickness in both failed and non-failed areas, so thickness alone may not be the cause of the coating problem. However, the importance of an objective investigation of all facts to determine root cause and corrective action cannot be overemphasized.