introduce

Coating thickness measurement is one of the common quality assessments in industrial coating applications. SSPC-PA 2, Procedure for Determining Consistency of Dry Coating Thickness Requirements is often referenced in coating specifications. As SSPC-PA 2 has evolved over the past forty years, many procedures and measurement frequencies are referenced in both the mandatory sections of the standard and non-mandatory appendices. While measuring frequency was never intended to be a statistical process, it is helpful to understand the statistical implications of the measurement process. It is helpful to know whether the coating thickness variation is reasonable. This short article examines how scanning probe technology can help obtain more measurements (in a relatively short period of time) to better assess the consistency of coating thickness, especially in larger, more complex on the structure.

background

Scan image courtesy of Elcometer Ltd.

There are two industry standards that are widely used to measure coating thickness. These include ASTM D7091, Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic Coatings and Nonmagnetic Coatings Applied to Nonferrous Metals and SSPC-PA 2, Determining Compliance with Dry Coatings Procedure for thickness requirements. ASTM standards focus on the use of gages, while SSPC standards focus on the frequency and acceptability of coating thickness measurements. These standards are intended to be used in conjunction with each other. In 2012, all references to frequency of measurement were removed from the ASTM standard, so it does not conflict with SSPC-PA 2.

The frequency of coating thickness measurements is determined by gage readings, point measurements and

DeSelsko Corporation Offers FXS Tips That Can Withstand Rough Surfaces

Area measurement. Obtain a minimum of three (3) gage readings in a 1.5" diameter circle and average them to produce point measurements. Obtain five point measurements over an area of 100 square feet. The number of areas to measure is determined by the size of the coated area Decision. If coating less than 300 sq. ft. (i.e., during a work shift), measure each 100 sq. ft. gage reading). If the size of the coated area is between 300 and 1000 square feet, select and measure the area from 3 to 100 square feet. If the size of the coated area exceeds 1000 square feet, measure in the first 1000 square feet Three areas, measuring one additional area in each additional 1,000 square feet or a portion thereof. For example,

Other measurement frequencies are included in the non-mandatory appendices to SSPC-PA 2, including Appendices 2 and 3 for steel beams, Appendices 4 and 5 for test panels, Appendices 6 for measuring coating thickness along edges, and Appendices 7 for pipe exteriors.

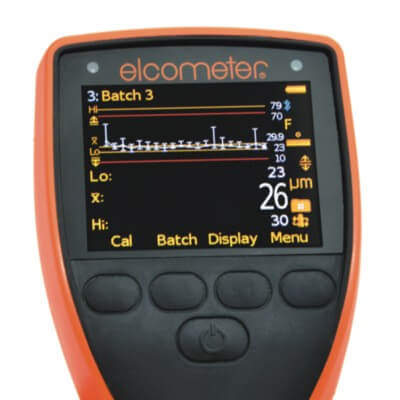

Meter display with scan data, courtesy of Elcometer Ltd.

Gage readings, point measurements, and area measurements prescribed by SSPC-PA 2 were never intended to be based on statistical procedures. Instead, the frequency of measurements is based on what is reasonable in the shop or in the field to adequately characterize the thickness of the coating without unduly hindering production. If you need to measure every 100 square feet, consider checking the effect on 4,000 square feet of steel that was applied the day before. That's 40 zones, 200 points measuring at least 600 gage readings. And that frequency might not be considered a statistically significant sample either. Furthermore, obtaining additional measurements (when invoked by contract) above the amount prescribed by SSPC-PA 2 may be considered "overchecking".

Use Scanning Technology for Higher Data Volumes

Several manufacturers of electronic coating Thickness Gauges have incorporated "scanning probe" technology and associated supporting software into the data acquisition process. This newer technology enables strain gage operators to obtain a large amount of coating thickness data in a relatively short period of time. For example, coating thickness data was obtained by a certified paint inspector during an actual bridge repainting project that included 12 batches of readings (nearly 600 readings) in just 8 minutes (measurement time only) , a bridge spanning four panel points. Thus, a more representative sampling of the coated area can be obtained without hindering production. However, there are concerns about acquiring such large datasets, such as data curation, dealing with outliers,

The SSPC Dry Film Thickness Measurement Committee may consider adding a 10th non-mandatory appendix to SSPC-PA 2, giving specifiers the option to obtain a larger data set of coating thickness measurements without hampering production. In this way, the owner can gain greater confidence in the uniformity and consistency of the applied film.