1. Paint leaks from the seal between the gun needle and the gun nozzle

Turn off the compressed air and open the valve of the paint tank, so that the air pressure of the paint tank drops to zero, so as to prevent the compressed air and compressed paint from rushing out during the process of dismantling the Spray Gun, which will cause harm to the human body , and then remove the gun needle and nozzle Remove it, and carefully check whether the seal is damaged. If the seal is damaged, then only replace the Spray Gun 3-piece set (nozzle, gun needle, air cap), otherwise no matter how you clean it, the paint leakage The problem. If the sealing parts of the two are not damaged, clean the gun needle and gun nozzle with thinner (note that the seal is strictly prohibited to clean), then blow it clean with compressed air, install and debug.

2. Leakage of compressed air from the front end of the Spray Gun

Turn off the compressed air and open the valve of the paint tank, reduce the air pressure of the paint tank to zero, pull the valve seat of the Spray Gun out of the Spray Gun, and then deal with it according to different situations.

The seal of the air valve is damaged. If the seal ring is damaged, replace the valve seat seal ring. If there is dirt on the seal ring, wipe it clean with cleaning agent and install it.

The thimble adjustment position is wrong, pull out the thimble from the gun body, adjust the two small adjustment nuts on the upper end of the gun needle, the adjustment method for air leakage is to put the two small nuts close to the head of the gun needle, and then install them after adjustment. Pay attention that when pulling out the gun body, the gun needle should not touch hard objects to prevent damage to the gun needle, otherwise it will cause paint leakage.

3. No paint is sprayed out when the Spray Gun is working

(1) There is dirt clogging between the Spray Gun and the nozzle. The treatment method is to clean the nozzle and then blow it off with compressed air.

(2) For the pressure-feed Spray Gun, the reason may be that the control air pressure of the Spray Gun is too low, and the control valve of the Spray Gun does not fully open the passage between the thimble and the nozzle, so that the paint cannot be sprayed out. The solution is to increase the control air pressure.

(3) The atomization air pressure is too high, so that the paint treatment method is to reduce the atomization air pressure of the Spray Gun so that the two air pressures are basically equal.

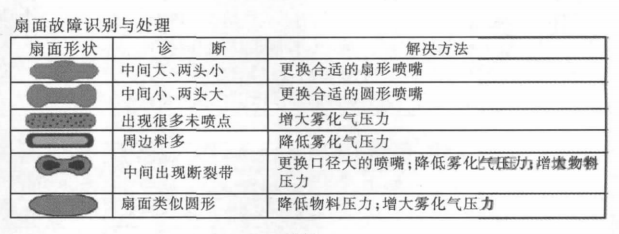

6. Adjustment of the spraying fan surface of the Spray Gun

After spraying with the Spray Gun, the surface coverage of the sprayed object is sometimes uneven. Refer to the several and adjust the fan properly to obtain a satisfactory spraying effect.