1. Application in gold plating and copper plating industries. During the cleaning process of electroplating, it is necessary to use a compressor to remove the water on the surface of the object, and the use of an oil-free Air Compressor can keep the electroplating smooth.

2. Medical industry application. The medical industry, including pharmaceutical manufacturing, medical instrument air supply, etc., all need to use clean compressed air, and the air supply of the oil-free machine just meets this standard, and the oil-free machine is popular in the medical industry.

3. Laboratory application. Laboratories often use air supply equipment to assist in the actual operation. Once the compressed air is not chaotic enough, it is easy to react with chemical substances, resulting in the failure of the actual operation, and in severe cases, it will cause safety accidents.

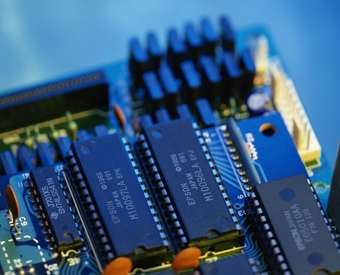

4. Applications in the electronics industry. The electronic industry has very precise requirements in the production of components, and every detail must not be missed.

5. Application in chemical industry. It is mainly used to improve the quality of chemical products, ensure its process and production safety, and so on.

6. Application in mining industry. Many minerals are flammable and explosive, and many of them are underground. The use of oil-free machines reduces the accident safety rate.

At present, the oil-free Air Compressor is improved and developed on the basis of the oil-filled Air Compressor. There are two main methods: one is to replace the oil with water, and the other is to coat the rotor with a self-lubricating coating, because the rotor The bearings running at high speed at both ends need oil lubrication, so it is necessary to seal the lubrication space of the rotor bearing and the compression space of the rotor. It is precisely because of this high-speed sealing that the machining accuracy of the oil-free Air Compressor is quite high, and the cost paid It is very big. And there is a huge problem that even the best technical seal will be damaged. Once the main engine head of the oil-free Air Compressor fails, because it is too accurate, the main engine head can only be repaired by the manufacturer, which greatly increases Unrepairable, even if it can be repaired, it will cost a huge amount of money and a long time for maintenance. Therefore, it is better not to buy oil-free Air Compressors blindly if it is not a super large enterprise.

Oily and oil-free in the Air Compressor generally refer to the oil content of the gas discharged from the Air Compressor exhaust port. Generally, the oil content of the oil machine is relatively large, and the oil content of the oil-free machine is 0.01ppm, so use this The oil content is used to distinguish the Air Compressor with oil and without oil. There is also a completely oil-free Air Compressor, which is not lubricated by oil, but is lubricated by resin materials, so the gas discharged in the end does not contain oil, which is called a completely oil-free Air Compressor, but the quality of this type of Air Compressor is currently It is not very satisfactory. The domestic general oil-free machine is oil-lubricated.

空压机储气罐中空气占有一定的空间,但它没有固定的形状和体积。在对密闭的容器中的空气施加压力时,空气的体积就被压缩,使内部压强增大。当外力撤消时,空气在内部压强的作用下,又会恢复到原来的体积。如果在容器中有一个可以活动的物体,当空气恢复原来的体积时,该物体将被容器内空气的压力向外推弹出来。这一原理被广泛应用在生产、生活中。例如:皮球里打入压缩空气,气越足,球越硬;轮胎里打入压缩空气,轮胎就能承受一定的重量。在大型汽车上,用压缩空气开关车门和刹车;水压机利用压缩空气对水加压,在工厂里,压缩空气用来开动气锤打铁;在煤矿里,它能开动风镐钻眼。压缩空气还用于管道输送液体和粒状物体。

Compressed air is the second largest power energy after electricity, and it is also a process gas source with multiple uses. Its application range covers petroleum, chemical industry, metallurgy, electric power, machinery, light industry, textile, automobile manufacturing, electronics, food , medicine, biochemistry, national defense, scientific research and other industries and departments. What is unsatisfactory is that compressed air contains a considerable amount of impurities, mainly: solid particles - in a typical large urban environment, there are about 140 million particles per cubic meter of atmosphere, of which about 80% are in size If it is less than 2µm, the suction filter of the Air Compressor cannot eliminate it. In addition, the inside of the Air Compressor system will continue to produce wear debris, rust residue and carbides of oil, which will accelerate the wear of gas equipment and cause seal failure; moisture--the relative humidity in the atmosphere is generally as high as 65% or more. After compression and condensation, it becomes wet-saturated air and entrains a large number of liquid water droplets. They are the root cause of corrosion of equipment, pipes and valves. Freezing in winter can also block the small hole channels in the pneumatic system. It is worth noting that even if the pure saturated air is separated from the net, as the temperature drops, there will still be condensed water. For every 10°C drop, the saturated water content will drop by 50%, that is, half of the water vapor into liquid water droplets. Therefore, it is necessary to use a multi-stage separation filter device in the compressed air system or to pretreat the compressed air into a dry gas with a certain relative humidity; Lubrication, sealing and cooling, but pollute the compressed air. Although the oil-less machine, semi-oil-free machine and all-oil-free machine developed with self-lubricating materials reduce the oil content in the compressed air, they also lead to the reduction of the life of the wearing parts, the corrosion of the inside of the machine and the piping system, and the air pollution. Side effects such as increased oil content during the run-in period, wear period and unloading period of the press. This is undoubtedly a threat to automated production lines pursuing high reliability. In addition, it should be emphasized that the oil carried into the system from the Air Compressor is not beneficial under any circumstances. Because after repeated high-temperature oxidation and condensation emulsification, the performance of the oil has been greatly reduced, and it is acidic, which not only fails to lubricate the follow-up equipment, but also destroys the normal lubrication; microorganisms -- in pharmaceuticals, biological engineering, food manufacturing and During the packaging process, the contamination of bacteria and phages cannot be ignored.