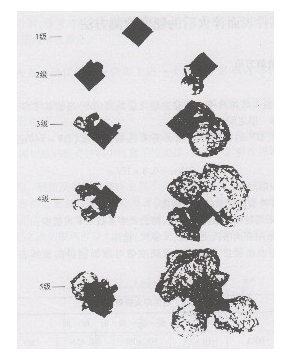

Nitriding layer brittleness test 1. Nitriding layer brittleness level is divided into 5 levels according to the cracking degree of the edge of the Vickers hardness imprint.

Nitriding layer brittleness classification table

level | Description of brittleness level of nitrided layer |

1 | The indentation corners are intact |

2 | Chipping on one side or one corner of the indentation |

3 | Indentation two sides or triangular fragmentation |

4 | Indentation Triple or Triangle Fragmentation |

5 | Indentation four sides or four corners broken |

Nitriding layer brittleness level diagram

98.07N (10kgf) detection force × 100

Nitriding layer brittleness test 2. To test the brittleness of the nitriding layer, a Vickers Hardness Tester is used. The testing force is specified to be 98.07 N (10 kgf), and the testing force needs to be added slowly (completed within 5 to 9 s). After adding the testing force, stop 5~10 s, and then remove the detection force.

In case of special circumstances, after negotiation, the detection force of 49.03N (5 kgf) or 294.21 (30 kgf) can be used, but it must be converted according to the table value.

Indentation level conversion table

Test N (kgf) | Indentation level conversion | ||||

49.03 (5) | 1 | 2 | 3 | 4 | 4 |

98.07 (10) | 1 | 2 | 3 | 4 | 5 |

294.21 (30) | 2 | 3 | 4 | 5 | 5 |

Nitriding layer brittleness inspection 3. Vickers hardness indentation is inspected under a microscope at 100 times magnification. At least three points shall be measured on each piece, and only when more than two points are at the same level can the grade be graded; otherwise, the test shall be repeated once.

Nitriding layer brittleness test 4. The nitriding layer brittleness should be tested on the working part of the part or on the surface of the furnace sample. Generally, the parts are qualified at grades 1 to 3, and the important parts are qualified at grades 1 to 2. Parts with wear marks can also be measured on the surface after grinding off the machining allowance.

Nitriding layer brittleness inspection 5. Parts after gas nitriding need to be inspected