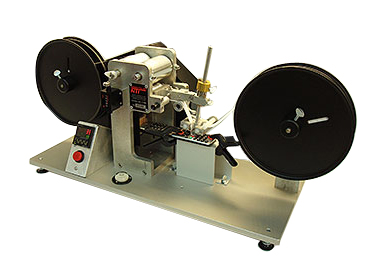

UV curing technology is a new green technology that came out in the 1960s. It has the advantages of fast curing speed, low production energy consumption, less pollution, and superior coating performance. This article introduces the RCA paper tape abrasion Tester used in the abrasion test of UV curable resin.

Preparation of wear-resistant coatings

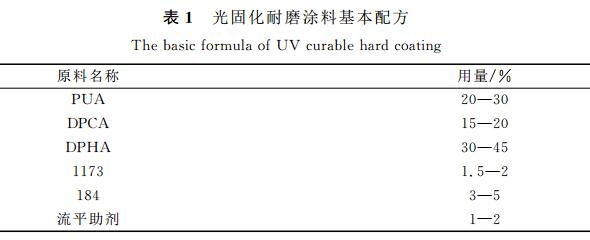

Add the photocurable resin and active monomer into the high-speed dispersion tank according to the ratio, stir at 60°C for 30 minutes at high speed, add the measured photoinitiator and leveling aid, disperse at high speed for 10 minutes and filter for later use. The basic formula is shown in Table 1 .

Preparation of PET hard coat

Through the RDS type wire Bar Coater, the prepared wear-resistant coating sample is evenly coated on the PET substrate, and the infrared leveling is carried out at a temperature of 60 ℃ for a certain period of time, and then UV curing is carried out on a UV curing machine. The thickness of the coating is 3μm-4μm, made of PET plus hard film.

Test Methods

Wear resistance: use RCA paper tape wear Tester, load 500g, rub 1000cycles, and then measure the transmittance;

RCA paper tape abrasion Tester

Discussion of results

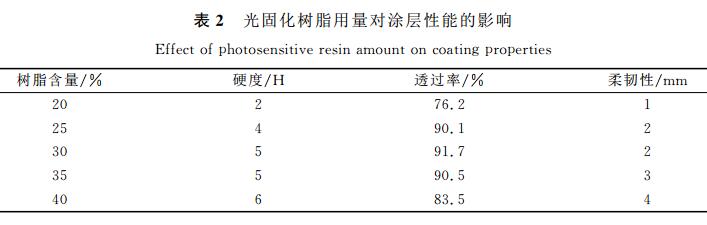

The effect of the content of modified polyurethane acrylate on the properties of the coating film is shown in Table 2. It can be seen from the table that as the amount of photocurable resin increases, the hardness of the coating increases, while the adhesion decreases, and the wear resistance is better. The performance of the coating is better when the dosage is 25%-30%.

Quoted from:

[1] Lv Jianbo, "Preparation of UV-cured Hard Coating for PET Optical Films" [J] Imaging Science and Photochemistry. 2011.11(6) 449-455