Materials and components are coated with layers made of different materials for different reasons. Regardless of practical reasons such as protection or decoration, it is important to measure the actual coating thickness of the coated material. PHYNIX gauges allow non-destructive thickness measurement of coatings and use two different methods: magnetic induction and eddy current principles:

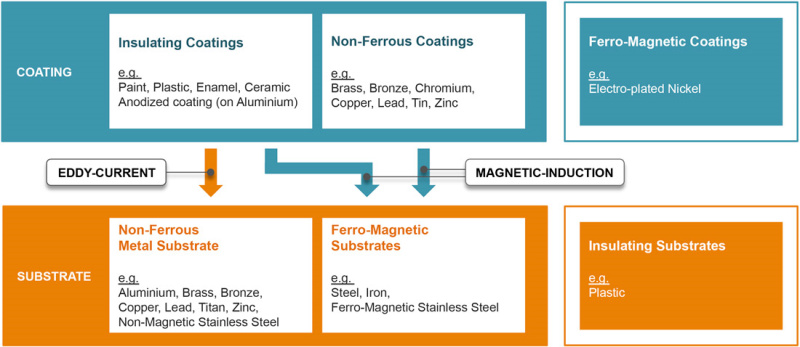

For non-destructive coating thickness measurement on iron and steel (i.e. ferromagnetic substrates), the principle of magnetic induction is used. The magnetic induction principle is used in models marked with F or FN (F = ferromagnetic), eg: Surfix® FN. Coatings need to be non-magnetic - eg, varnish, paint, enamel, plastic, glass, aluminum, lead, chrome, copper, brass, zinc, tin, etc.

The eddy current principle enables non-destructive coating thickness measurements on non-magnetic metallic substrates, eg. Aluminum, aluminum alloy, lead, bronze, copper, brass, zinc, die-cast zinc, tin. The eddy current principle is used on models marked N or FN (N = non-ferrous), e.g., Surfix® easy I-FN. Coatings to be tested need to be electrically insulating; for example, varnishes, paints, enamels, plastics, glass, anodized coatings and ceramics.

Typical Applications of Coating Thickness Gauge Using Magnetic Induction and Eddy Current Principles

All Surfix® models comply with special international standards for thickness measurement:

Method: DIN EN ISO 2808

Magnetic induction method: DIN EN ISO 2178, ASTM B499, ASTM D7091

Eddy current method: DIN EN ISO 2360, ASTM D7091

Basic terms of measurement technology: DIN 1319, Teil 1 and Teil 3

Sensor function

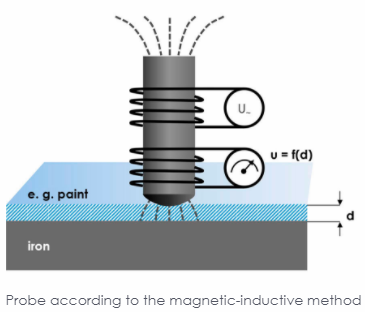

A field coil wound around an iron core and applied with a low-frequency alternating current is used for measurements according to magnetic induction methods (eg Modell Surfix F). For this purpose, a magnetic alternating field is generated in the air space around the poles.

When the poles are close to the iron part, the magnetic field will be amplified. It then generates a voltage in the second coil (measurement coil). This voltage depends on the distance from the iron. By attaching the iron core or measuring sensor to the coating, a defined distance and thus a defined coil voltage is produced between the pole and the iron. It is evaluated electronically and displayed digitally as coating thickness.

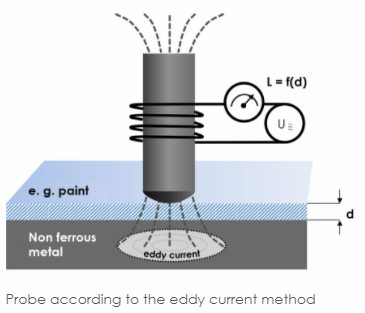

Measurements according to the eddy current method use only a single coil (eg model Surfix N) through which a high-frequency alternating current flows. This creates an electromagnetic alternating field around the coil.

When a coil with an alternating magnetic field approaches a non-ferrous metal, an alternating current is induced in the metal - called an eddy current. This creates another electromagnetic alternating field in the opposite direction, weakening the original field. The effect in the coil is the change in inductance, which is a characteristic of each coil. By applying the measuring sensor to the coating, a defined distance and thus a defined coil inductance is created between the coil and the non-ferrous metal. This will be electronically evaluated and digitally displayed as coating thickness.

In combination probes (e.g. type Surfix® FN), both coil systems are placed in the measuring sensor so that when the sensor is placed on the sensor, the alternating fields of both coils - low frequency and high frequency alternating fields - are affected. The object to be measured. The measurement signals of the two coils are automatically evaluated electronically by a microprocessor, so that regardless of whether the measurement is performed on ferrous or non-ferrous metals, the measurement program corresponding to the base material can be selected and the correct layer thickness displayed for the metal.