Abstract: Hand-feeling elastic paint, also known as hand-feeling paint, elastic paint, rubber paint, and rubber paint, is widely used in 3C electronic products, small household appliances, automotive interior parts, stationery, cosmetics, and daily necessities. As the country's requirements for environmental protection are getting higher and higher, water-based elastic paint is a new technology that is urgently needed in the market. Polymethyl methacrylate improves the RCA resistance, cold and heat cycle resistance and salt spray resistance of the coating. The designed water-based elastic hand paint has excellent hand feel, elasticity, abrasion resistance, alcohol resistance, salt spray resistance and artificial resistance. Ageing.

Elastic paint, also known as touch paint, rubber paint, rubber paint, is widely used in 3C electronic products (such as: U disk, mouse, mobile phone case, camera, etc.), small household appliances (such as: hair dryer, coffee pot, hair clip, etc.) , automotive interior parts (such as: door handles, decorative parts, etc.), stationery (such as: pens, pencil cases, etc.), cosmetics (such as: cosmetic boxes, eyebrow pencils, etc.) and daily necessities (such as: hangers, tea cups, glasses cases , umbrella handle, etc.) and other fields. It can enhance the feel and comfort in contact with people, and has higher requirements for the environmental protection, wear, feel, chemical resistance and service life of the paint film.

As the country's environmental protection requirements become more and more stringent, the country has successively issued a new "Environmental Protection Law", "consumption tax", "pollution discharge tax", and corresponding cities have issued a system to prohibit the production and use of oil-based paints in order to control PM2.5, prompting Traditional paints are developing in the direction of water-based. For the elastic paint market, oil-based elastic paints have the problem of poor long-term performance. In the November 2015 issue of "PCI Chinese Edition", a special long-lasting elastic paint with hand feeling was introduced. technology, thereby solving the service life problem of oil-based elastic paint. How to make the elastic paint water-based? Many manufacturers in the city are also engaged in the research and development of this kind of technology, but they have not been fully marketed. The author believes that the research and development of water-based elastic paint needs to focus on the following aspects:

1. How to realize water-based;

2. How to ensure the softness and smoothness of the hand feeling;

3. How to improve the wear resistance, chemical resistance and artificial aging resistance of the coating;

4. How to solve the adhesion on the plastic substrate and metal substrate at the same time.

The author here introduces the production method and application of a water-based elastic touch paint. This technology uses water-based elastic acrylic polyurethane emulsion as the main body, and the RCA friction and friction resistance of the ethylene-vinyl acetate and polymethyl methacrylate modified coating Salt spray resistance, the designed water-based hand-feeling elastic paint has excellent hand feeling, elasticity, abrasion resistance, alcohol resistance, salt spray resistance and artificial aging resistance, and has national patent technology protection.

Experimental part

Preparation of water-based touch elastic paint

Although water-based low-hydroxyl, low-softening point acrylic has certain elasticity, it is difficult to balance the hand feeling and dryness, while the ethylene-vinyl acetate copolymer emulsion has good hand feel and elastic strength (scratch resistance), polymethacrylate Although esters have poor hand feel, they have high tensile strength. This project uses three materials with completely different structures as the film-forming base material, and uses the hydrophilic isocyanate cross-linking agent to react with the hydroxyl component to form a two-component cross-linking system. HDI type isocyanate curing agent is exactly the same. Combining nano-SiO2, elastic powder, matting powder, hand feeling agent, wax powder, etc., not only ensures the hand feeling and scratch resistance of the coating, but also improves the RCA tape resistance, salt spray resistance and cold resistance of the paint film thermal cycling.

• raw materials

Water-based elastic acrylic polyurethane emulsion: commercially available (one containing a polyester segment with a high molecular weight, which makes the PUR composed of a higher flexible segment undergo microphase separation, which makes it have excellent flexibility, and the resin contains terminal -NH2 polyether as one of the components, and hydrophilic isocyanate to form a fast-curing polyurea coating part, which makes it have excellent elasticity and weather resistance), ethylene-vinyl acetate: ethylene-vinyl acetate, EVA, Elvax 40W (DuPont), polymethyl methacrylate (PMMA Jinan Rongfeng Chemical), matting powder: OK520 (Evonik, Germany), elastic powder: 5070D (Dainichi Seika), water-based hand feeling additive: XR-301 ( Xirun Chemical Industry), wax powder: polytetrafluoroethylene wax powder SST-3 (American clover), color paste: water-based resin-free nano-black paste (Foshan Sansheng Chemical), dispersant: PX4585 (BASF), defoamer : NXZ (Koning Chemical), leveling agent: 57 (Eminence Chemical), neutralizer: DMAE (Hays Chemical), hydrated magnesium silicate: AD (Haiyi Chemical), co-solvent: ethylene glycol mono Butyl ether (Dow, USA), HDI hydrophilic isocyanate: 2655 (Covestro, Germany), deionized water.

• Water-based Elastic Lacquer Formulation

The formulation of the water-based feel elastic paint designed for the experiment is shown in Table 1.

Mix water-based elastic polyurethane emulsion and co-solvent (polymethyl methacrylate and/or ethylene-vinyl acetate are also added to formulas 4-7), and stir at 500 rpm for 10 minutes; use half of deionized water to dissolve Add water-based dispersant, water-based defoamer, and water-based leveling agent to the production tank after dilution, and stir at 500 rpm for 5 minutes; while stirring at 500 rpm, add nano-color paste, elastic powder, matting powder, and water-based Hand feeling aid, hydrated magnesium silicate, disperse for 40 minutes at 1200 rpm; use the remaining deionized water to adjust the paint viscosity to 18-24S (T-4 cup), add neutralizer, and control the pH value at 8- between 9.

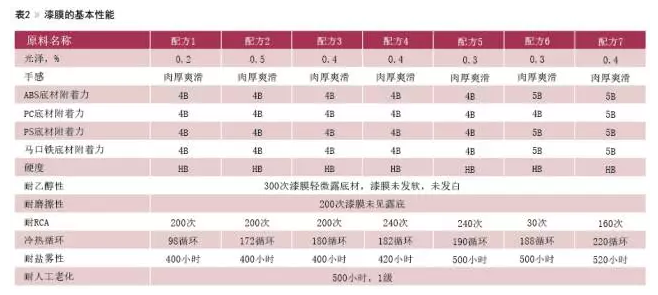

Board making: Water-based touch elastic paint and HDI hydrophilic isocyanate curing agent are adjusted according to 10:1, and deionized distilled water is used to adjust the spraying viscosity, and the spraying viscosity is adjusted to 13-15S (NK-2 cups), using 70 ~80℃×30~40min. Spray on ABS, PC, PS and tinplate sheets respectively, and control the film thickness of the dry board for ethanol resistance and RCA test at 20-40µm. Physical properties of the paint film The dry board is maintained at room temperature for 48 hours, and the type inspection item is tested after the dry board is maintained at room temperature for 7 days. The gloss of the paint film is tested according to GB1743-1989; the adhesion of the paint film is tested according to GB/T9286-1998; the hardness of the paint film is tested according to GB/T6739-2006; the alcohol resistance of the paint film is tested according to SS-00208 (99.7% anhydrous Ethanol, 1KG force, back and forth for one time); paint film abrasion resistance is tested according to SS-00208 (512 sand rubber, 1.5KG force, back and forth for one time); paint film resistance to RCA tape friction is tested according to ASTM F2357-04 Testing; the cold and hot cycle of the paint film is tested according to MOTOROLA.INCG.7 (place the dry board under the condition of -20°C-+60°C, the humidity is 90%, and 2 hours is a cycle); the paint film is resistant to artificial aging The performance is tested according to the QUVA artificial aging in GB/T1865-1997.

Results and discussion

The author passed multiple sea selection tests, and finally selected an elastic acrylic polyurethane resin emulsion, combined with HDI hydrophilic isocyanate curing agent, combined with elastic powder, hand feeling aid, wax powder, and matting powder, so that the paint film is in Excellent adhesion and smooth feel on different substrates;

It can be seen from formula 1-2 that when the amount of elastic acrylic polyurethane emulsion is lower than 35%, the resistance to cold and heat cycles of the paint film is obviously much worse, so the amount of elastic polyurethane emulsion is increased to 35-40% in the following tests %carry out testing;

It can be seen from formulations 4-5 that the addition of polymethyl methacrylate and ethylene-vinyl acetate can significantly help the elastic paint film's resistance to RCA tape friction, resistance to cold and heat cycles, and resistance to salt spray;

It can be seen from formula 6 that when unmodified polymethyl methacrylate and ethylene-vinyl acetate are added at the same time, the resistance to RCA paper tape friction is significantly worse, from more than 200 times normally to 30 times, but the resistance to salt Fog performance has been improved;

It can be seen from formula 7 that the polymethyl methacrylate modified by nano-SiO2 through the solution preparation method and the paint film made by splicing ethylene-vinyl acetate at the same time have excellent RCA friction resistance and salt spray resistance The resistance to cold and heat cycles are significantly improved;

Nano-scale resin-free color paste is used in formula design, which changes the double-layer process of "base color paint + colorless matte elastic paint" used in the past oil-based elastic paint, reducing the coating cost;

After passing the test, this water-based colored elastic paint can be widely used in 3C electronic products, small household appliances, automotive interior parts, stationery, cosmetics, daily necessities and other fields.

epilogue

The author mainly introduces a water-based elastic polyurethane emulsion and HDI hydrophilic isocyanate curing agent as the main raw materials, which are modified with nano-SiO2 modified polymethyl methacrylate and ethylene-vinyl acetate, so that the produced water-based Hand-feel elastic paint has excellent adhesion, hand feel, RCA tape resistance, abrasion resistance, salt spray resistance and artificial aging resistance on different substrates. This technology has been released to the country on October 11, 2014 The patent office applied for patent protection, which was authorized in May 2016 (patent number: CN 104231901 A), obtained Chinese patent protection, and is vigorously promoting it to the market.

Reprinted from PCI Magazine.