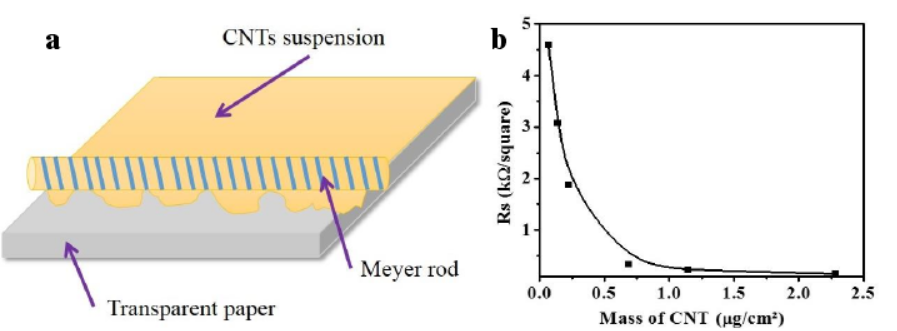

Through the reasonable design of the paper structure, the transparent paper can be combined with nano-materials to endow the paper with special functions, thereby exaggerating the application fields of paper and not only limited to information recording and packaging. Carbon nanotubes have attracted worldwide attention since they were discovered by Japanese scholars in 1991. It has the advantages of light weight, high mechanical strength, excellent mechanical and conductive properties, etc. It is an excellent material for manufacturing electronic devices, and is widely used in the preparation of various transistors, displays, quantum resistors, super conductive fibers, transparent electrodes, etc. [191-201] . In this paper, carbon nanotubes are used to prepare paper-based transparent electrodes. The CNT dispersion of 1 mg/ml is spread uniformly on the smooth surface of the transparent paper by bar coating, which endows the paper with excellent electrical conductivity without affecting the transparency of the paper. Figure 2-8a is the process of coating CNTs dispersion on the surface of transparent paper. The relationship between the coating amount of CNTs and the surface resistance is shown in Figure 2-8b. With the increase of the amount of CNTs, the conductivity of the paper sheet increases rapidly. When the coating amount of CNTs is 0.7μg/cm2, the surface resistance of transparent paper is already less than 500Ω/□. Continuing to increase the coating amount of CNT, the electrical conductivity of the paper does not increase much. The transverse structural diagram of CNTs-coated transparent paper is shown in Figure 2-9a. A uniform and thin interwoven network of CNTs is deposited on the pure NFC layer. Effectively improve the conductivity of transparent paper.

Since paper is a kind of material with strong hydrophilicity, in the case of water, the fibers are prone to swelling and deformation of the paper. During the construction of the device, considering the large-scale production of the device, it is generally used Some existing mature technologies are used to prepare devices, and aqueous coating is a simple, easy-to-roll method for roll-to-roll production. However, water-based coatings can cause changes in paper shape during application and paper coating. The shape stability of the substrate has an important impact on the construction process and device performance of the subsequent paper-based electronic devices. Therefore, in the process of device preparation, paper deformation should be avoided as much as possible.