0 Preface

The coating industry is one of the largest application markets for titanium dioxide, accounting for about half of the total consumption of titanium dioxide. How to ensure the application performance of titanium dioxide for coatings is the basis for all large titanium dioxide manufacturers to gain a foothold in the industry. For coatings, the main application performance indicators of titanium dioxide are: dispersibility, oil absorption, hiding power, weather resistance, gloss, whiteness, etc. Theoretically speaking, the weather resistance of titanium dioxide is determined by the quality of the titanium dioxide inorganic coating, and the hiding power, gloss and whiteness are determined by the quality of the titanium dioxide itself. The organic coating agent mainly affects the dispersion and oil absorption of titanium dioxide. Quantity matters.

Therefore, titanium dioxide production enterprises mainly focus on the two indicators of oil dispersibility and oil absorption when evaluating the performance of organic coating agents. The survey found that the results obtained by the oil dispersibility and oil absorption measurement methods commonly used by titanium dioxide production enterprises are not completely consistent with the evaluation results of paint users. The main reason is that the measurement systems and evaluation standards of the two parties are inconsistent.

1 Determination methods of oil dispersibility and oil absorption in titanium dioxide production enterprises

1.1 Determination of oil dispersibility

1.1.1 Instruments and medicines

PM240-Ⅲ flat Grinder, scraper fineness Tester (0-8), adjusting knife, standard slurry, absolute ethanol.

1.1.2 Preparation steps of titanium dioxide slurry

Weigh 3 g of titanium dioxide sample (accurate to 0.01 g), 3 g of standard slurry (accurate to 0.01 g) and 2 g of standard slurry (accurate to 0.01 g) for use.

(1) Transfer all 3 g of standard slurry to the flat Grinder, then pour 3 g of sample on the standard slurry, mix thoroughly with a spatula, then place the titanium dioxide slurry in the center of the flat Grinder, and grind;

(2) Set the rotation speed of the flat Grinder to 25 r, grind 4 times, and collect the slurry on both sides of the flat Grinder at the center of the flat Grinder with a knife adjustment each time;

(3) After 4 times of grinding, scrape off the slurry on one side of the flat Grinder, and add 2 g of standard slurry to the slurry on the other side;

(4) After mixing thoroughly, grind 4 times at 25 r, and the slurry after grinding is ready for use.

1.1.3 Determination steps of oil dispersibility

(1) Clean the scraper fineness gauge with alcohol and cotton cloth;

(2) Take a large drop of ground slurry (it is advisable to fill the groove of the scraper fineness meter a little more) and place it at the 0 scale of the scraper Fineness Meter;

(3) Hold the scraper with the thumb, index finger and middle finger of both hands, make the scraper perpendicular to the surface of the scraper fineness gauge, and pull the scraper from the deep part of the groove to the shallow part at an appropriate speed;

(4) Immediately (not more than 5 s) pinch the Fineness Meter horizontally and tilt it so that the line of sight and the groove plane form an angle of 15~30° to the light to observe the scale value of the evenly exposed particles (more than 4) in the groove. The reading value is the oil dispersibility data of the measured slurry.

1.2 Determination of oil absorption

1.2.1 Instruments and medicines

Scales, spatulas, glass plates, refined linseed oil.

1.2.2 Determination steps of oil absorption

Accurately weigh 1 g (accurate to 0.01 g) of the sample to be tested, place it on a glass plate , add refined linseed oil drop by drop, grind and press evenly with a spatula until the sample is completely wet (the sample can form a ball, Lightly pressed and scattered), record the quality W of refined linseed oil consumed.

Oil absorption V=1/W

2 Evaluation method of oil dispersibility and oil absorption of titanium dioxide in paint manufacturing enterprises

2.1 Instruments and medicines

High-speed stirring and dispersing machine, scraper Fineness Meter (0~100 μm or 0~ 50 μm), absolute ethanol.

2.2 Titanium dioxide slurry formula

The formulation of titanium dioxide slurry is shown in Table 1.

2.3 Preparation steps of titanium dioxide slurry

称量分散罐的质量(m 1 ),然后将表1中1~3号原料加入罐中,在分散机中于800 r/min转速搅拌均匀(约2 min),再加入钛白粉,清理分散罐周边的钛白粉,将转速调至2 500 r/min,15 min后加入二甲苯,在800 r/min搅拌约1 min,称量此时的质量(m 2 );用m 1 +400-m 2 后之差为补充醋酸丁酯量,再将其搅拌均匀(800 r/min,约30 s)即可。

2.4 油分散性测定步骤

(1) 用酒精和棉布擦净刮板细度计 ;

(2) 取一大滴研磨好的浆料(以充满刮板细度计沟槽而略多为宜)置于刮板细度计0刻度处 ;

(3) 以双手拇指食指及中指持刮刀,使刮刀与刮板细度计表面垂直,以适宜的速度将刮刀由沟槽的深部向浅部拉过 ;

(4) 立即(不超过5 s)横捏细度计并倾斜,使视线与沟槽平面成 15~30° 角对光观察沟槽中颗粒(4个以上)均匀显露处的刻度值,此读数值即为所测钛白粉浆料的油分散性数据。

2.5 吸油量测定

涂料企业并不会去真正地测定钛白粉的吸油量,而是通过测定钛白浆料体系的黏度来表征钛白粉的吸油量。

2.5.1 仪器设备及药品

水浴锅,旋转黏度计,温度计(0~100℃),调漆刀,冰箱,400 g样品罐。

2.5.2 黏度测定步骤

(1) 用调漆刀将样品装入400 g样品罐中(装入质量约400 g),再用温度计测定所测试样品的温度,并将其温度控制在30℃,若温度高则用冰块降温至30℃,若温度低则用水浴锅加热至30℃ ;

(2) 用旋转黏度仪(通常选3~4号转子)测定样品的黏度。

3 油分散性和吸油量测定结果差异实例

从上述油分散性和吸油量测定方法可见 :钛白制造商和涂料制造商对钛白油分散性和吸油量的测定存在差异。

3.1 油分散性

钛白制造商只是用单一树脂浆料作为分散介质,而涂料制造商却是用树脂(可能是一种树脂,也可能是多种树脂)、稀释剂、分散剂的复合体系作为分散介质。不同的树脂,就存在极性大小、分子结构、官能团等差异,同一种钛白,在不同树脂应用体系中的油分散性测定结果存在较大差异性。

3.2 吸油量

钛白制造商是通过定量钛白吸附亚麻油的多少来评定钛白粉的吸油量,而涂料制造商则According to钛白在树脂、稀释剂、分散剂为分散介质而制成的钛白浆料的黏度来评定钛白的吸油量,有可能会出现钛白制造商测定吸油量大的产品,在涂料制造商处因钛白浆料黏度低而得出吸油量低的结果。

3.3 测定结果差异实例1

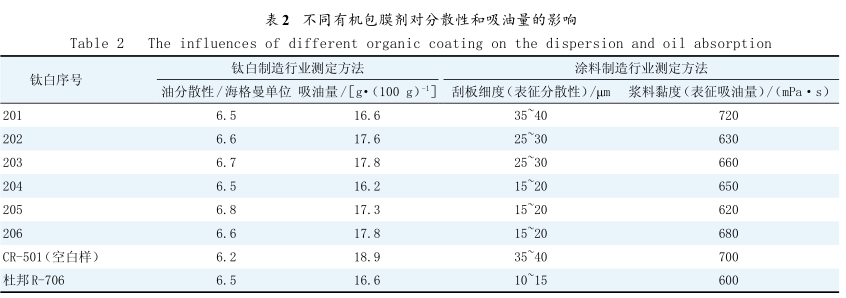

采用锦州钛业的CR-501为钛白基料,用道奇威(成都)科技有限公司提供的不同有机包膜剂,按相同的包覆量(1.0%,相对于钛白质量)对钛白进行有机包膜,然后进行测定。

(1) 实验设备

砂磨机 :耐驰(上海)机械仪器有限公司 ;气粉机 :绵阳昊泰公司。

(2) 实验工艺

在带有高速搅拌装置的容器中加入适量纯净水,开动搅拌,然后加入有机包膜剂,搅拌2 min ;加入钛白粉打浆3 min ;砂磨15 min ;将钛白粉浆料于120℃烘干 ;用多功能粉碎机预粉碎 ;气粉解聚。

(3) 样品测定

分别采用前述的钛白制造商和涂料制造商的评定方法进行测定,结果列于表2。

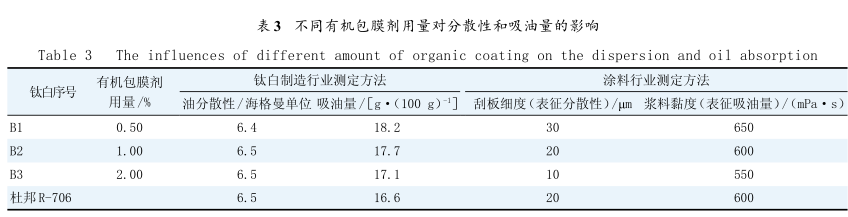

3.4 测定结果差异实例2

仍采用锦州钛业的 CR-501 为钛白基料,以及前述钛白样品制备工艺,并用相同的有机包膜剂,但按不同的包覆量进行包膜,然后分别采用钛白制造商和涂料制造商的评定方法进行检测,结果列于表3。

3.5 实验结果分析

由表2可见 :涂料制造商测定结果与钛白制造商测定结果并不能一一对应,钛白制造商认为分散性差不多的样品,在涂料制造商处却存在较大差异。钛白制造商认为分散性好、吸油量低的钛白粉并不能代表其在涂料制造商处会有同样的结果。原因就在于二者的评定方法完全不同。

4 结语

Due to differences in measurement systems and evaluation methods, titanium dioxide manufacturers and paint manufacturers have large differences in the evaluation . Therefore, how to establish a scientific evaluation system is very important. As a titanium dioxide manufacturer, in order to provide better services to titanium dioxide users and make the application performance of titanium dioxide meet the needs of users as much as possible , we should not rely solely on our own laboratory when selecting the type of organic coating agent and determining its dosage. According to the test data, it is believed that the amount of organic coating agent should only meet the dispersibility index proposed by the customer, but they do not know that the measurement systems and evaluation methods of the two parties are different. It should be based on the application data of the paint manufacturer and the customer 's standard. It is the responsibility of every titanium dioxide production technician to constantly understand the customer's needs and evaluation standards.