0 Preface

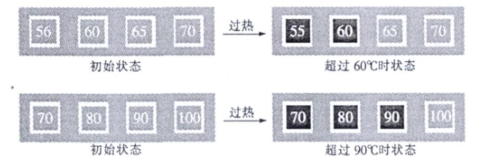

The foreign name of the color-changing temperature measuring patch is generally called "Temperature Indi-cating Recorder Labels", namely: "Temperature Indi-cating Recorder Labels". As a relatively new temperature measurement technology, the patch adopts temperature-sensitive color-changing temperature measurement technology, which can be attached to the measured part, and changes the color or displays the temperature number with the change of the temperature of the measured part, and thus can grasp the temperature of the measured part. The temperature changes of the parts are shown in Figure 1.

Figure 1 Schematic diagram of over-temperature indication of the temperature measuring patch

Color-changing temperature patches are especially suitable for parts, external surfaces, and objects in life-threatening environments that cannot or are difficult to measure with ordinary thermometers. Such as transistors , integrated circuits, chemical reaction tanks, engine bearings, conductive busbars, switches, joints, transformers and other heating parts temperature measurement.

The allowable error of the temperature point of the color-changing temperature measuring patch is generally ±2°C. In order to facilitate the user to evaluate the color-changing temperature accuracy of the color-changing temperature measuring patch, the supplier of the color-changing temperature measuring patch suggested a simple comparison test method.

The specific method is: affix temperature-measuring patches of various temperatures on the outer wall of a square metal bucket in turn, pour a small amount of cold water, insert a thermometer prepare a certain volume of boiling water, and start the test. First slowly pour a small amount of boiling water. In order to keep the temperature of the water uniform, stir it with a thermometer. As the water temperature rises, when the thermometer value rises to the discoloration temperature, you can see the color change of the temperature measuring patch corresponding to the temperature.

The main problems in the above method are: it is difficult to guarantee the uniformity and stability of the temperature field of the color-changing temperature measuring patch, the composition of the calibration system and the calibration method are not standardized, and it does not meet the basic requirements of traceability.

Therefore, according to the actual needs of on-site temperature measurement patch discoloration temperature calibration, our unit has developed a sticking device for The calibration of three measurement indicators, temperature measurement resolution and discoloration irreversibility, realizes the reliable guarantee of the temperature measurement results of discoloration temperature of the temperature measurement patch.

1 Introduction of application device for color change temperature calibration of temperature measuring patch

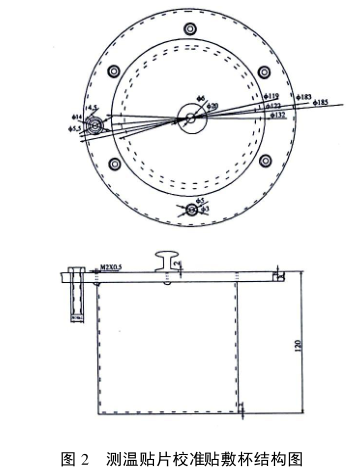

The application device for color change temperature calibration of the temperature measuring patch (hereinafter referred to as the application device) adopts a cup structure made of red copper, and refers to the calibration method of the thermometer.

The standard mercury thermometer is used in conjunction with the constant temperature bath, making full use of the good thermal conductivity of copper and the constant and uniform temperature of the constant temperature bath to complete the accurate and reliable calibration of the discoloration temperature of the temperature measurement patch.

The structure of the application device is shown in Figure 2. The device consists of a copper cup body, an upper edge of a Bakelite cup body and a heat-resistant glass lid.

2 Calibration method and steps of color change temperature of temperature measuring patch

2.1 Cleaning the surface of the application device and applying the patch

The brass mouth cup structure application device is mainly used to apply the temperature measurement patch . Before application, clean the inner bottom and side of the cup, and then firmly apply the temperature measurement patch to the inner wall surface.

2.2 Application device and standard thermometer installation

Place the application device at the upper port of the constant temperature Bath (Water/Oil), install a standard mercury thermometer vertically at the thermometer socket, insert it into the constant temperature area of the constant temperature Bath (Water/Oil) liquid surface, and the temperature sensing bubble of the standard mercury thermometer is at the same level as the bottom of the cup. on a horizontal section, and located in the constant temperature zone of the constant temperature Bath (Water/Oil).

2.3 Calibrate temperature presets

Set the first preset temperature calibration point, the preset value is 3°C lower than the lowest .

2.4 Constant temperature Bath (Water/Oil) constant temperature

Heat up the constant temperature Bath (Water/Oil), and when it reaches the preset temperature calibration point, observe the indication value of the standard mercury thermometer. After the temperature is stable for 5 minutes , observe whether the color of the temperature measuring patch changes through the observation window of the application device, and record the temperature.

2.5 Raise the temperature step by degree to calibrate the temperature measurement error of the temperature measurement patch

Each time the temperature is increased by 1°C, repeat the process of step 2.4, and record the corresponding nominal temperature point t. The corrected temperature value t 1 of the standard mercury thermometer temperature reading, t 1 is the actual discoloration temperature point, continue to heat up until the temperature patch completely changes color, record the corrected temperature value t 2 of the standard mercury thermometer temperature reading.

读取标准水银温度计温度示值时 , 视线应与温度计垂直, 读取液柱弯月面的最高点 ,读数要估计到分度值的1/10。

依此类推,校准其它贴片标称变色温度点测温误差 Δt 。

2.6 测温贴片测温误差计算

对应任一贴片标称变色温度点 ,采用式(1)计算测温贴片变色温度误差 Δt 。

Δt = t -t 1 (1)

2.7 测温贴片温度分辨力计算

对应测温贴片任一标称变色温度点 t ,测温贴片温度分辨力 f 用式(2)计算 。

f =((t 1 - t 0 )+(t 2 - t 1 ))/2 (2)

2.8 测温贴片颜色变化不可逆性评价

所有测温贴片标称温度点校准完成后,停止升温, 观察测温贴片最终颜色 ;然后将贴有测温帖片的帖敷装置从恒温槽中取出,放置在室温条件下,5min 后再次观察测温贴片颜色,比较帖敷装置从恒温槽取出前后两次测温帖片颜色变化情况,评价测温前后颜色变化的不可逆性。

2.9 测温贴片温度校准实例

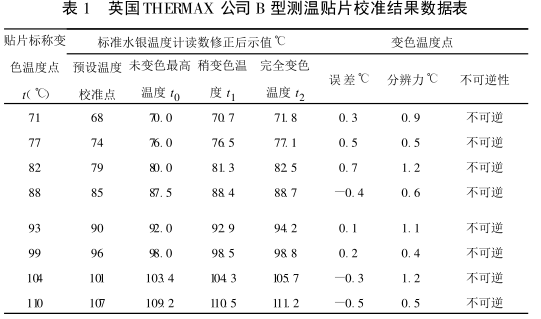

对英国 THERMAX 公司生产 B 型测温贴片进行了校准 。校准结果如表1 所示。

3 结论

通过设计测温贴片变色温度校准用帖敷装置 ,并与标准水银温度计和标准恒温槽配套使用, 能够满足测温贴片变色温度校准需求, 确保测温贴片温度测量结果准确可靠 。

参考文献

[ 1] 英国 THERMAX 公司.测温贴片使用说明.

[ 2] 李吉林等.温度计量.北京:中国计量出版社, 1998.

[ 3] 栾恩杰等.热学计量.北京:原子能出版社, 2002.

作者简介

Guan Jun, male, senior engineer. Work unit: AVIC Shenyang Liming Aero Engine (Group) Co., Ltd. Product Inspection and Testing Center. Mailing address: No. 6, Dongta Street , Dadong District .

Chun Li, Ge Jiquan, Xiao Hongjun, AVIC Co., Ltd. Product Inspection and Testing Center (Shenyang 110043).