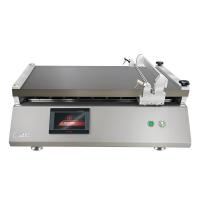

This article is a description of the specific operation steps of the Pushen AFA-II automatic film coating machine:

Steps

1. Connect the power supply.

2. Put the substrate to be coated (such as black and white paper) flat on the coating base, turn on the Vacuum Pump switch to the "adsorption" position, at this time, the coating substrate is absorbed on the coating base. (Note: When the size of the substrate to be coated is smaller than the size that can be vacuumed, use other paper or transparent tape to cover the redundant vacuum holes, so as to avoid the substrate to be coated from being weakly adsorbed and causing coating failure.)

3. Place the horizontal push rod on the fixed rods on both sides of the coating base.

4. Select the appropriate coating length (I-230mm, II-285mm), press the "reset" button to make the horizontal push rod reach the initial position of coating.

5. Place the wet film preparer in front of the horizontal push rod.

6. Adjust the speed control knob to choose the appropriate coating speed.

7. Place an appropriate amount of coating to be applied directly in front of the wet film preparer.

8. Press the "Start" button to start coating.

9. After the coating stops, scrape the remaining paint into the waste collection tray.

10. Turn off the Vacuum Pump and remove the finished sample for the next operation.

Precautions

1. The coating base should be kept clean, and no debris should stick to it, so as not to affect the flatness of the coating base, thereby affecting the next coating; if the paint is accidentally dropped on the coating base, it should also be cleaned in time .

2. After determining the size of the coating substrate, seal the unused small holes around the vacuum suction cup with transparent tape to improve the adsorption effect.

3. Check the oil level of the oil cup regularly. If the oil level is found to be insufficient, add lubricating oil in time to lubricate the guide rail.

4. After each use of the device, it should be covered with a dust cover to prevent dust from falling into the vacuum holes and being sucked by the Vacuum Pump, which will affect its service life.

5. After each use of the equipment, the waste collection tray should be cleaned in time.

6. During the film coating process, do not turn the "coating length" switch, otherwise the machine will stop running.