Why does the coating bar scratch the silver line? The result of this case is that there is a problem with the dispersion of the customer's product raw materials.

One night, a colleague called and said that a customer's newly purchased RDS wire Bar Coater had scratches, and you should help him to solve it.

For this kind of problem, the first reaction is not to doubt whether it is a problem with the wire rod, because the RDS wire rod coater that NBCHAO has sold for so many years has not yet encountered the use of RDS wire rod coater due to quality problems. scratched. So it is estimated that there is a problem somewhere. Let's look at the analysis below. The picture below shows the beginning and end of the chat.

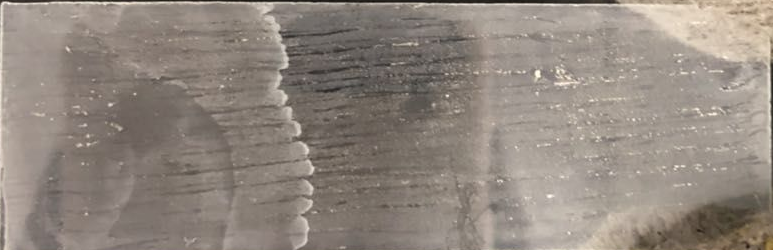

Enlarge the customer's sample picture as follows:

In fact, judging from the picture sent by the customer, there are obvious silver powder particles on it. On the one hand, the silver powder and emulsion in the customer's silver thread solution are not fully integrated; fusion. Either way, the result is the same. In fact, before scraping with an online Bar Coater, it is necessary to ensure that the coated sample is fully stirred evenly, and impurities and particles that are too large will cause scratches on the coating film.

For this case, further share the possible reasons for the scratches.

First, ensure that the coated ink or paint is fully stirred evenly before coating, so that the cause of scratches caused by sample impurities or excessive particles can be ruled out first;

In addition, observe whether the scratches are a few or evenly distributed. If a few scratches may be partially blocked by dust, the special performance is "deep first and then shallow". If it still appears after careful cleaning, please use a magnifying glass to observe with the naked eye. Whether the steel wire/groove has variation due to bumping; if the scratches are evenly distributed, please first judge whether there is a leveling problem caused by too high a consistency. In general, the wire rods produced by RDS are wound with precise steel wires, and the circular cross section of the steel wires is an important part of the process. The flatness and consistency of the groove flow channel is an important part of the process, and we are also confident that it will not be caused by this. This may appear on some low-end or rough-crafted wire rods, but we regard this problem as a problem on RDS products. A very good competitive advantage over other coating sticks.