Preparation before operation

1. Prepare the microscope

1. The microscope light source is powered by two AAA batteries. To place the battery, unscrew the back of the torch. Place both batteries with the "+" side down (towards the light bulb).

2. It is necessary to manually install the light source into the clamp bracket of the microscope, as shown in Figure 1.

3. The angle between the microscope barrel and the light source needs to be set to 60°. (figure 2)

4. Adjust the focus and scale of the microscope before reading.

5. Turn the ring and rotate the scale as needed (Picture 2, No.1)

6. Place the microscope on a flat surface, turn on the light and adjust the focus on the sample by rotating the large knurled ring (Fig. 2, No. 2)

2. Prepare the timer

1. Set the indentation time to 30 seconds in T1, button "S"

2. The recovery time 35 s is set in "T2" with "S". These values are now stored in memory until © (Clear) is selected.

Measurement steps

The test shall be carried out at a temperature of 23±2°C and a relative humidity of 50±5%.

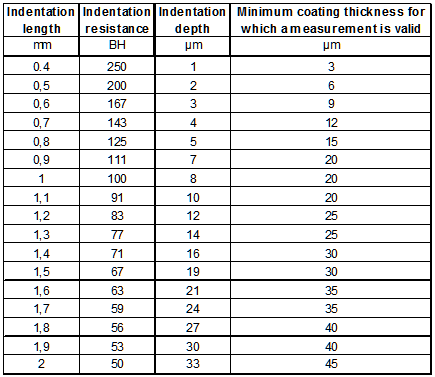

1. Measure the coating thickness minimum 3-45μm (according to Table 1)

2. The coating to be tested should be smooth and clean.

3. Use the level gauge to ensure that the test plate is level with the test surface.

4. Use the template to mark the points to be measured (3) and the foot positions (1 and 2) on the test object. The indentation will be visible at the gap in the middle of position 3 (red mark in picture 3).

5. Check the indentation bodies (weights, wheels and fixing points) to make sure they are free of dust.

6. With no tilting or lateral movement, place the indentation body on the test panel, place the feet first exactly on the marked positions 1 and 2, and then carefully lower the indenter until it touches the panel. (picture 4) and start T1 on the timer

7. After 30 seconds remove the TQC Buchholz indentation Tester from the surface and start T2 on the timer. Be careful not to apply any pressure to the indenter when removing.

8. After a recovery period of 35 seconds, measure the indentation length (L) with a measuring microscope. (Figures 5a and 5b)

9. Find the indentation length (L) in Table 1 and find the corresponding Buchholz indentation resistance (BH) value, or use the formula BH = 100/L

Table 1 - Relationship between indentation length and indentation resistance

Calibration method

We recommend annual calibration. For calibration, please send the instrument together with the RMA form* to TQC in the Netherlands.

Maintenance

• The device is durable and precision machined. Never drop or hit it.

• Always clean the instrument after use.

• Clean the instrument with a soft dry cloth. Never use mechanical means such as wire brushes or sandpaper to clean the instrument. This may result in the use of aggressive cleaning agents, causing permanent damage.

• Always store the instrument in its case when not in use.

• We recommend annual calibration.