test preparation

1) Apply the paint film to the largest test panel 100 x 150 mm, with a maximum thickness of 1 mm. Carefully apply dry film.

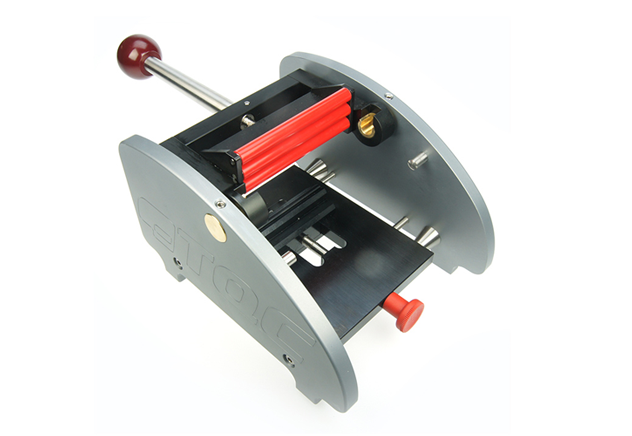

2) Install the unit on the table with the grip wheel on the left side.

test steps

Remark

Test results are strongly dependent on the selected test panel, coating thickness, drying conditions and environmental conditions (see ASTM D522)

Note any deviations in reproducible test results.

1. Open the device fully and insert the mandrel to the correct diameter. Turn the handle of the pressure roller counterclockwise.

2. Place and fix the test board in the device close to the mandrel. Hold it upright in the clamp. Once bent, the coated side of the panel should face outward.

3. Pull the handle, the movement is smooth, it takes 1-2 seconds to bend 180°.

4. Release the test panel from the test equipment and check the results immediately.

Maintenance

• The device is durable and precision machined. Never drop or hit it

• Always clean the instrument after use.

• Clean the instrument with a soft dry cloth. Never use mechanical means such as wire brushes or sandpaper to clean the instrument. This may result in the use of aggressive cleaning agents, causing permanent damage.

• Do not use compressed air to clean the instrument.