Steps

1. Prepare the film (coating material) to be tested, either in self-supporting or non-self-supporting form. one. Self-supporting coatings are better formed with non-stick substrates, such as silicone-coated paper. Suitable nonstick substrates may vary depending on the application.

Samples can be cut to size by using the sealing ring as a cutting guide.

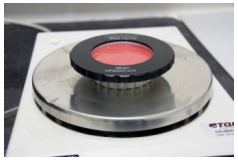

2. Fill the permeable cup with the specified volume or fill the edge with the required liquid to a specified distance, or use the dry desiccant to fill the dry cup method.

3. Place the pre-cut sample on the sealing ring and align.

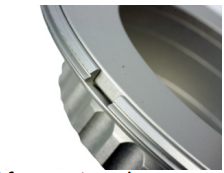

4. Put the sealing ring with the sample on the flange of the cup so that the film is between the cup flange and the sealing ring. Take care that the seal is properly aligned with the pin on the outside of the flange.

5. Place the sealing ring and tighten it by hand.

6. Weigh the component and record the mass in grams (M1) by means of a balance suitable for determining the change in mass of the test component. A balance with a resolution of 0.001 g is considered suitable.

7. Place the cup into the test environment described in the standard and leave it undisturbed for the time specified in the test protocol/standard.

8. Weigh the assembly and record the weight (M2) periodically until the mass loss per hour is linear.

9. Calculate the water vapor transmission rate of the film in grams/square meter/day (g/(m2/d)). The formula needed to calculate depends on the method used to dry or wet the cup.

10. In order to open and clean the cup after the test, it is better to use the opening on the side of the cup to release the seal.

11. After testing, always store clean cups in a dry environment.

Caution

• Always clean the instrument after using a suitable solvent.

• Never clean the instrument mechanically by wire brushing or sandpaper. This can cause permanent damage with aggressive cleaning agents.

• Regularly inspect the instrument for defects.