SilcoTek Materials Surface Characterization Capabilities®

The inescapable role of material surface characterization capabilities in support of SilcoTek® Coating Science and R&D efforts. The ability to effectively evaluate surfaces is key to developing new inert barrier coating products and plays an important role in helping customers scale up and handle troubleshooting.

A variety of surface characterization techniques enable SilcoTek scientists to study materials, analyze surface bonding mechanisms, and gain insight into surface properties.

What tools are needed to characterize surfaces?

Coating surface characterization begins with a capable and knowledgeable R&D team. Tools to help analyze surfaces vary by application and need, but here are some of the tools we use to understand surfaces.

X-ray Fluorescence (XRF) Analyzers

To avoid process disruptions caused by incompatible substrates, SilcoTek uses a Thermo Scientific X-ray fluorescence (XRF) analyzer, a non-destructive elemental analysis tool, to identify any unfamiliar incoming metal substrates. Where other paint companies might guess what the base metal is, we know what we're painting!

FTIR

Fourier Transform Infrared Spectroscopy (FTIR) uses broadband infrared radiation as an excitation source to probe the molecular structure of various chemicals in gaseous, liquid or solid state. SilcoTek technicians regularly perform QA/QC duties using FTIR technology, and SilcoTek scientists assist with their R&D projects.

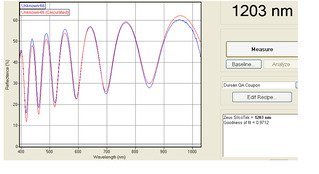

F20 Thin Film Analyzer

SilcoTek's F20 Thin Film Analyzer (manufactured by Filmetrics Inc.) is a benchtop tool that can be configured to measure film thickness (30Å to 350 mm), optical constants (n and k: refractive index and extinction coefficient), and transmittance. It is primarily used by SilcoTek as a fast, accurate and non-destructive method of measuring surface thickness.

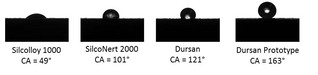

Surface contact angle measurement

The contact angle is the angle formed by a drop of liquid with its (usually solid) contact surface. By drop measurement, an angle is formed between the solid surface and the liquid meniscus near the contact line. The contact angle gives an indication of the wettability of a surface to a liquid (usually water), and the value of the contact angle can vary with the volume of the droplet.

SilcoTek scientists rely heavily on contact angle measurements in studying the development of hydrophobic and superhydrophobic surfaces, where properly engineered surface topography can produce extreme water repellency on a surface.

Contact angle measurements are beneficial to SilcoTek customers: ensuring the desired surface hydrophobicity/hydrophilicity for the application; confirming successful surface bonding.

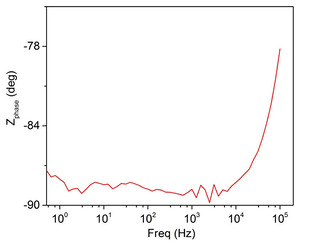

Electrochemical Impedance Spectroscopy (EIS)

Electrochemical impedance spectroscopy (EIS) is a non-destructive and very useful tool for studying and evaluating the performance of protective coatings on metallic substrates. Measurements provide information related to coating performance and failure processes, such as resistance, capacitance, double layer capacitance and Faradaic impedance.