Metals are in just about everything we use, from the cars and trains we work in to the computers and phones we use throughout the day. In this blog, we've discussed the myriad applications of metal, but an important factor that makes metal very useful is its coating.

Coatings give metals valuable properties: corrosion resistance, wear resistance, weldability, machinability, hardness, brightness, adhesion and lubricity (reduces friction in moving parts). Industries that rely on coatings include automotive, aerospace, medical devices, construction and electronics. The metal is coated with various substances including chromium, nickel and zinc.

Chrome: Chromeworks works with many substrates. Decorative chrome is used to improve appearance, while hard or industrial chrome is very resistant to corrosion, wear and abrasion. Hard chromium is used in the nuclear, aerospace and automotive industries as well as in the manufacture of many tools and medical devices.

Nickel: Nickel is a multi-purpose coating; it is aesthetically pleasing, corrosion-resistant, abrasion-resistant, stress-resistant and magnetic. Nickel can be formed into sheets with little or no stress, making it particularly suitable for electroforming or aerospace applications, according to the product surface treatment article. Nickel is used in engineering applications to improve wear resistance and to provide a barrier layer in coins, jewelry and circuit boards. In strip steel and aerospace applications, nickel is used for low stress or sizing.

Zinc: Zinc works with a variety of substrates, but is often used to coat steel to prevent corrosion. There are many methods of applying a zinc coating to steel, but the common ones are hot-dip galvanizing and continuous galvanizing.

A common coating process is conventional electroplating. Other processes include electroless plating, galvanized coatings (commonly applied to steel, iron, and aluminum), physical and chemical vapor deposition, anodizing, mechanical coating, pickling, etching, and sputtering.

Why is coating thickness measurement important?

Coating materials need to be applied in a certain thickness specification to express the desired properties. Metals that are too high or too low will not have the desired effect. Overplating also wastes expensive coating material. If inaccurate coating thickness is not detected, the entire coil may eventually be scrapped. Read Are you wasting expensive steel coating material? learn more.

Handheld XRF: Welcome to the Paint Thickness Measurement Market

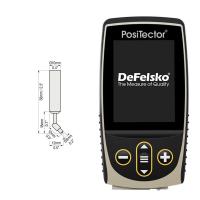

Coating thickness measuring instruments can be used as in-line process measurement systems for metal manufacturing. Hand-held, application-specific tools are often used for finished products. A lesser known but very effective technique for spot analysis of metal coatings in any application is portable X-ray fluorescence (XRF). XRF is a non-destructive analytical technique that measures fluorescent (or secondary) X-rays emitted by a sample when excited by a primary X-ray source. The signal intensity can be used to determine the thickness of the coating; a second reading can determine the thickness of the substrate. Handheld XRF instruments can be used anywhere in the supply chain, from incoming goods inspection to confirmation testing of completed subassembly parts to final product quality control. XRF coating thickness measurement method complies with international standards ASTM B568-98 and ISO3497:2000.