How to measure small surface areas with a gloss meter?

An instrument has been used to resolve gloss differences on holograms, measuring polish on coins, steering wheels and extruded pipes.

The Miza GJ-10800 Gloss Meter has a very small measuring spot of 2mm for measuring gloss of very small sections or resolving gloss differences across small areas.

To obtain the same reading as a standard gloss meter on slightly irregular surfaces, it is recommended to take an average of several readings.

How to measure irregular surfaces with a gloss meter?

When measuring irregular or textured surfaces, small measurement areas can give different gloss values compared to standard gauges with larger measurement areas. In order to produce comparable results, 10 measurements were made on the Novo-Curve Gloss Meter and the average reading was calculated using a statistical function.

How to measure the glossiness of a surface?

All standard gloss meters are designed for use on flat surfaces and if used on a curved surface, the measuring beam will reflect off the instrument Detector causing false readings. The more the surface is curved, the greater the error.

The solution to this problem is to use very small regions. The light is slightly scattered by the curved surface, but as long as the reflected beam remains narrow enough to stay within the instrument's Detector, the reading will be correct. Novo-Curve gloss meters are designed for this purpose and are suitable for very small diameter cylinders and spheres. The Novo-Curve Gloss Meter was jointly developed with the National Physical Laboratory (NPL).

How often should instruments and standards be recalibrated?

It has been seen that a standard plate kept in very good condition can become contaminated and become 2 GU within three years.

Standards used in "working" conditions require periodic calibration or inspection.

The one-year period between board recalibrations should be considered the minimum period. If at any time a calibration standard becomes permanently scratched or damaged, it needs to be recalibrated or replaced immediately.

International standards state that tiles are calibrated and traceable, not gloss meters, however, it is recommended that the instrument be sent to an approved service center to have its operation verified annually or bi-annually, depending on operating conditions

How do I recalibrate the instrument?

Gloss meters are very stable and require infrequent calibration. To tell when calibration is required, simply place the gloss meter on the calibration plate and take a test reading. If less than 0.2 GU from the specified calibration value, no recalibration is required.

Are there other ways to describe gloss?

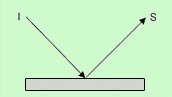

(1) Specular gloss

The ratio of light reflected at the specified angle to

light incident on the surface at the same angle on the other side of the surface normal

ģα S A generation

(3) Contrasting Gloss (also known as Gloss and Haze) Gloss at grazing

incidence and viewing angles

ģα S A generation

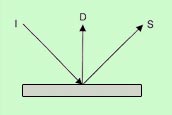

The ratio of specularly reflected light to

diffusely reflected light normal to the surface

Gα d small

(4) no bloom

Measures no haze or milky appearance adjacent to specular light

GαB-D. A generation

(5) The clarity of the image

Clarity of Specular

Reflected Light

dR of ģα Dθ

(6) No surface texture gloss Perception of surface smoothness and uniformity overall visual assessment

Several problems that may be faced when choosing a Gloss meter

Guess you like it

Relevant knowledge

- 1Gloss inspection method of slurry inks

- 2Principle and Application of Glossiness Tester

- 3Working Principle and Application of Metal Gloss Meter

- 4Basic principle and application analysis of insulating paint gloss Detector

- 5Working principle and application analysis of film Glossmeter

- 6Principle and application analysis of microporous gloss meter

- 7 FZ/T 01097 Analysis of fabric gloss test method

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Coating coatings - Determination of surface gloss and Gloss meter