Since coatings such as paints, varnishes, conversion coatings, and related coating products are subject to impact damage during their manufacture and service life, this impact resistance test method has been found useful in predicting coating impact resistance. ASTM D 2794 provides a method for rapid deformation of coating films and their substrates by impact and is used to evaluate the effects of such deformation.

The organic coating to be tested is applied to four or more suitable thin metal panels. After the coating has cured, a standard weight is dropped a certain distance to hit an indenter which deforms the coating and substrate. Indentation can be intrusion or extrusion. By gradually increasing the distance the weight is dropped, usually 1 inch (25mm) at a time, the point at which failure typically occurs can be determined.

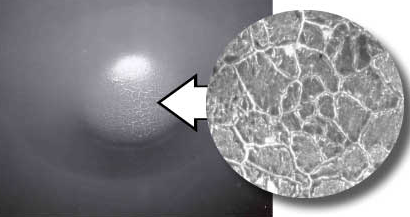

The film will usually break (see image below), made more apparent by using a magnifying glass, by applying a copper sulfate (CuSO4) solution to the steel, by using a pinhole Detector, or by tape - tensile test to determine the amount of coating removed .

Once visible cracks were identified, the test was repeated five times at that level, and five times above and below that level. Of course, these confirmatory tests are performed in random order, so consecutive tests are not performed at the same height or on the same panel.

Reference: ASTM D2794 Standard Test Method for Effect of Organic Coatings on Rapid Deformation (Impact)

Relevant ASTM standards include:

ASTM D1186 - Test Method for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Bases;

ASTM D609 - Practice for the preparation of cold-rolled steel panels for testing paints, varnishes, conversion coatings, and related coated products;

ASTM D823 - Practice for producing uniform thickness films of paints, varnishes, and related products on test panels.