You probably know that Rotational Viscometers work by measuring torque on the vertical axis of a rotating spindle. The spindle is located in the test sample and its rotation is blocked in proportion to the viscosity of the sample. These instruments measure viscosity.

this is very simple.

Most Rotational Viscometers also have a similar appearance. However, Rotational Viscometers use two distinctly different torque measurement systems. This option is not obvious when you look at different viscometer models.

spring system

As the name suggests, the system uses a design that includes springs. The system uses a spring to capture the torque tension on the spindle.

As the name suggests, the system uses a design that includes springs. The system uses a spring to capture the torque tension on the spindle.

These systems use a set of calibrated springs. Manufacturers who use spring systems offer three to four spring series. Each range is associated with a viscosity range. Three to four separate instruments are required to cover the standard viscosity range (1 cps to 100,000,000 cps).

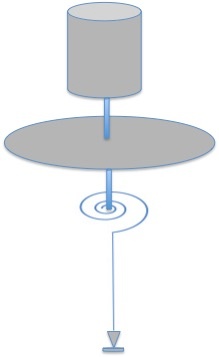

The spring viscometer system is based on the pivot and spring concept. The pivot/spring assembly rotates on an axis. The spindle is attached to this component. As the spindle rotates, the fluid's resistance to the spindle causes the spring to deflect. This deflection is proportional to the torque induced by the viscosity of the sample. This relationship to viscosity is calculated automatically.

The spring system provides high measuring accuracy, especially in the low viscosity range. This advantage is negated by the limited measurement range of any single spring/pivot set or instrument.

Because it is a delicate system based on a spring structure, special care is required to protect it from unwanted influence and damage. Also, as with all spring systems, the calibration needs to be checked and adjusted frequently.

server system

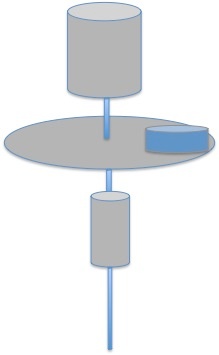

The second system used to obtain torque is sometimes called a servo system. This uses a precision servo motor to drive the shaft. Like the spring system, the main shaft is connected directly to the shaft rather than a pivot.

Determine the current required to drive the shaft at the test speed. This current determination is made using a servo encoder that determines the rotational speed and a microprocessor that calculates the current required to drive the servo at the set speed. As the spindle spins, the fluid's resistance to the spindle causes the system to use more current to keep the spindle running at a set speed.

Current is an indirect measure of torque, but it is directly proportional to viscosity.

Servo viscometers provide a wide range of viscosities (eg 1 cps to 100 million cps) in a single instrument. These systems are also stronger than spring systems. Additionally, servos allow for greater torque and speed ranges. Servos rarely need to be recalibrated.

Due to some additional friction in the servo system, the accuracy is lower at low speeds and low viscosities than with a spring system.

Spring and servo viscometers look the same

Aside from some differences in spindle mount design, it is difficult to judge a spring system viscometer with a servo system viscometer. The main differences are:

1. The viscosity of the servo system usually ranges from 1 cps to 100 million cps.

2. Spring systems typically require four different instruments to cover the same range as servo systems.

3. Servos rarely require calibration.

4. The spring system requires frequent calibration (more frequent use).

choice puzzle

We found significant differences between the basic measurement systems of Rotational Viscometers. Your next thought is, no doubt, "So what? Why should I care?"

As with most measurement systems, each type has a range of options such as touch screen, programmable test, data management and automatic test control. These options are not part of this narrative.

Instead, fundamental and often unnoticed financial and operational considerations of different torque measurement systems are closely related to smart viscometer model selection.

The difference between the two measurement systems (spring and servo) has implications for operational factors such as the level of attention required for calibration checks, recalibration work and record keeping activities.

The higher cost of the servo system can be decisively overcome if the measurement needs to span more than one spring system range. In this case, only one servo system is required compared to at least two complete spring systems.

We hope this discussion of the differences between viscometer torque measurement systems provides some assistance in the evaluation of Rotational Viscometer models.

As we keep proving to ourselves. Simple instrumentation questions that first arise lead to intricate answers.