介绍

我们在材料测试行业的多年表明了为测试机配备正确的夹具和夹具的重要性,因为如果使用正确的夹具或夹具,机器只能满负荷使用。有了所有可用选项,为您的测试应用选择合适的附件可能比您想象的更复杂。

握把和固定装置主要按两个重要因素分类:它们将用于的测试类型及其容量。重要的是避免夹具过载,因为这不仅会损坏夹具,还会损坏称重传感器和机架。本文将重点介绍用于拉伸测试的夹具,并指导您完成确定正确拉伸夹具的步骤,以便进行测试。

握把遇到的常见问题

多功能试验机夹具经历的三个常见的问题是

标本从抓握面滑落

样品在夹具面处断裂

由于其非标准形状或尺寸,无法牢固地抓住样品

标本滑点

样品滑移可能不仅是因为样品的材料特性,而且还是由于与所选夹具相关的各种原因:

夹紧力不足以抓住样品

为了获得更高的夹紧力,我们建议切换到气动夹具。几乎每个ADMET手柄都配有手动和气动夹紧机构。

夹爪面的表面区域可能没有覆盖足够大的表面区域来保持样品

最拉伸试验标准建议夹持至少四分之三个试样表面面积,以确保将试样握紧并准备经受拉伸试验。ADMET夹爪有各种尺寸可供选择。

钳口表面可能不是您的样品材料的正确类型

为了选择较合适的钳口,请与我们的销售工程师讨论样品的具体情况和测试应用。

样品在夹具面处断裂

某些标本可能不会从夹具上滑落,而是在夹紧面处向右突破。在测试过程中观察样品的行为并注意样品如何破裂是很重要的。如果断裂位于钳口面的线上,则记录的断裂强度将不能准确地表示实际的断裂强度。有几种方法可以处理样品破损:

如果使用手动虎钳夹具,请务必检查样品上的手动夹紧力是否过高。

如果使用气动夹具,则调整测试压力以找到称心的夹紧力,该夹紧力足以避免滑动但不会过度并导致夹具面处的试样断裂。

夹具上试样断裂的另一个原因可能是由于锯齿状锯齿的锯齿损坏了试样。在这种情况下,我们建议切换到另一种钳口类型或使用定制的锯齿状钳口组。

如果手动虎钳或气动夹具解决方案不起作用,我们建议使用不同设计的夹具,如织带或偏心滚轮夹具。这些夹具的设计使得样品和方形夹爪之间没有接触。

难以测试的尺寸/形状的样品

What if your sample is so large or small and has a non-standard shape that finding the right fixture is next to impossible to imagine? This can also be an issue if you are interested in testing the final product, not just the material of the final product. Most of the time, the solution is looking at non-standard fixtures, which are not always listed in the product catalog, or have custom fixtures designed for your testing needs.

An example is a fixation device used to hold a needle. The quick solution our engineers came up with was a Luer lock to the adapter clamp, as shown in the photo to the right.

Five Things to Know Before Buying a Tensile Test Fixture

With these items in mind, you can avoid common problems with tension grips by understanding five key factors in choosing the right grip for your application.

Item #1 - Different Types of Fixture Design

Tensile test grips include manual grips, pneumatic grips, wedge grips, hydraulic grips, rope and thread grips, webbing grips, clamping and self-tightening grips. It goes without saying that the importance of selecting a more suitable tensile fixture to effectively fix the sample is important for obtaining accurate measurement of tensile properties.

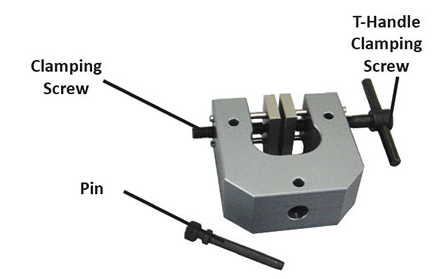

A common tensile grip is the vise grip. ADMET offers vise grips with one or two T-handles.

Figure 1 - Manual Vise Grip Diagram

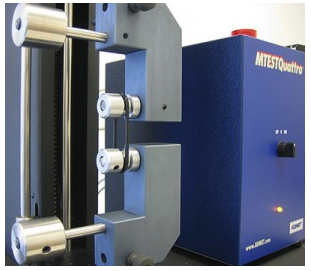

Figure 2 - Sample centered using wedge grips

Due to the specifications by which they are designed, some tension grips can be limited to a specific capacity or limited to the opening width of the jaws. For example, manual vise grips up to 50kN. Pneumatic grips can test samples up to 30kN, but the opening width of the jaws decreases as capacity increases. Higher volume samples such as metals are often tested using wedge grips. Wedge grips are commonly used with ASTM E8 metal testing with an optional alignment tool to ensure axiality of the applied load.

Rope, thread, winch and webbing grips come with custom designs specifically for testing certain materials such as ropes, threads, straps and yarns.

Figure 3 - Scissors Fixture

Figure 4 - Hook Clip

The scissor grip has a wide opening width and wide jaws, so it can be used for samples with non-standard shapes, such as plastic strips.

Hook jigs, loop test jigs, and O-ring tensile test jigs are examples of non-standard solutions that can provide better options for your material.

Figure 5 - O-Ring Tensile Fixture

Item #2 - Grip Surface (Jaw)

通过改变抓握面类型,可以使用相同的抓握来测试各种样品。在不知道样品材料的规格的情况下难以建议抓握面。某些ASTM标准将包括建议的抓握面,但大多数将由操作员According to样本材料的特性和尺寸决定。

| 握脸 | 描述 |

|---|---|

空白 | 空白,光滑的钳口是钢面钳口表面,没有任何涂层。它们通常与薄膜和箔一起使用。 |

橡胶 | 橡胶钳口有橡胶涂层,建议用于生物材料和纸样品。 |

锯齿/金字塔 | 锯齿形或金字塔形夹爪是带金字塔表面的镀镍钳口。它们被建议用于ASTM D412橡胶测试,ASTM D638塑料测试和ASTM E8金属测试。 |

钻石 | 金刚石颚表面由于其合成金刚石涂层而类似于砂纸表面。 |

波 | 波形钳口通常与柔性材料一起使用,这些材料固定在5mm波之间。 |

V-大白鲨 | V形钳口与圆形样品一起使用。在做出最终决定之前,请务必检查每个V形钳口的直径规格。此外,V形钳口可能并不总是适合中空管样品。如果通过它们插入销,则可以用扁平钳口测试管样品。 |

线路联系 | 线接触钳口采用光滑的镀镍表面,在钳口中间有3mm线。线夹可为塑料薄膜和薄板材料提供更好的抓握力。 |

ADMET还为上述所有颚表面类型提供快速更换系统。对以更快的方式从一种钳口类型更换为另一种钳口类型感兴趣的用户可以使用具有快速更换载体的钳口。

图9 - 快速更换夹具面

项目#3 - 握力

拉伸夹具用于获得样品拉伸性能的结果,如拉伸强度,峰值载荷,伸长率,拉伸模量和屈服。

不同材料显示不同的材料特性。在选择夹具之前,请确保您对测试样品所需的最大力量有信心。

液压夹具是最高容量的夹具,可以达到3,000kN的容量。

楔形夹具也适用于需要高容量的材料,如金属和复合材料,最高可达500kN。

手动虎钳夹具是多功能拉伸夹具,最高可达50kN。

气动夹具与橡胶和塑料样品一起使用,因为它们只能达到30kN。

夹紧夹具与低容量样品一起使用,例如电子元件和生物材料。夹紧夹具可达到的最大力为2kN。

织带抓地力范围从5kN到200kN。随着织带手柄的容量增加,卷筒直径和容纳的样品宽度也增加。

绳索夹具最高可达50kN。

Threaded clamps are commonly used with wires, wires, yarns and fishing nets with capacities from 200N to 5kN.

Item #4 - Specimen material and geometry and their effects

Final products, and more often internal component materials with different properties, can be tested for tensile properties using a multipurpose testing machine. Common materials tested in tension include adhesives, biomaterials, composites, plastics and elastomers, metals, paper and textiles.

Each material is first prepared for testing in a specific geometry, usually outlined in the test standard. Common specimen geometries include flat dog bones or cylindrical geometries such as tubes and bars.

Sample preparation can be done by machining or die cutting. ADMET offers molds that meet specific testing standards. Sample preparation is important and often specific. An example is ASTM D638, which describes five different specimen sizes that need to be selected based on the properties of the material being tested.

Figure 10 - ASTM D638 Die Specifications

Often, hard specimens such as metals, composites, and certain plastics are difficult to secure properly because premature fracture and slippage are common. Therefore, it is recommended to use high clamping force clamps, such as hydraulic clamps and wedge clamps. In contrast, rubber and elastomers are easier to hold in various handle designs such as manual vise grips, pneumatic grips, wedge grips, or eccentric roller designs. Common and easy-to-use grips are manual vises or pneumatic grips with rubber-coated or serrated jaw faces.

Figure 6 - ASTM C297 Custom Test Fixture

In addition to specifying the test method, some test standards also specify a fixture design that is used exclusively for tests compliant with that standard. Examples of tensile grips designed to specific standards include ASTM C297, ASTM D1414, and ASTM D3039.

Item #5 - Adjusting/Installing the Fixture to the Test Machine

Figure 7 - Male End Adapter for Fixture Mounting

The last item on the list is to hook up the fixtures on the Tester. Because the grips are not connected to the electronics of the multiTester, they can be used with any make and model. ADMET tensile test grips are typically mounted to Instron, MTS and Tinius Olsen frames using adapters.