Roller coating (rolling machine coating) is a coating method that first uses a rotating roller to pick up the paint, and then uses the rotating roller to contact the object to be coated during the rotation process, and coats the paint on the surface of the object to be coated to form a continuous coating film. Roller coating is suitable for the coating of thousands of flat and strip-shaped objects, widely used in the coating of metal plates, plywood, cloth or paper, especially for the coating of thousand metal coils.

principle

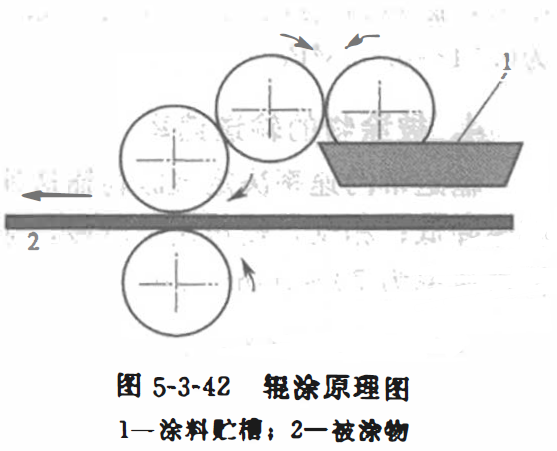

The principle of the roller coating method is that the roller rotates in the paint tank, adheres a certain amount of paint, forms a wet film of a certain thickness on the surface of the roller, and then uses the roller to contact the object to be coated during the rotation process, and coats the paint on the surface of the object. On the surface of the coating, a continuous coating film is formed, as shown in Figure 5-3-42. Roller coating is especially suitable for baking coatings, which require good leveling, wettability and adhesion, and can be baked and cured in a short time to form a film. Roller coating is easy to achieve continuous production operations, with fast coating speed and high production efficiency.

The structure of the roller coater

1. Structure

The roller coater consists of a paint pan, a take-up roller and an applicator roller, as shown in the figure. The paint tray is used to store the prepared paint; the function of the take-up roller is to take the paint from the paint tray and transfer the paint to the coating roller; the coating roller applies the paint to the surface of the object to be coated, and then obtains continuous coating film. Each roller is equipped with an adjustment device, which can adjust the gap and pressure between the rollers in order to obtain the required film thickness.

2. Drive mode

The drive mode of the roller is divided into collective drive and single roller drive. The collective drive is driven by a motor, and the process parameters are not easy to change, so it is rarely used at present. Single roller drive is equipped with a dedicated motor for each roller, the direction of rotation and speed can be adjusted, and the process parameters are easy to change, so it is widely used at present.

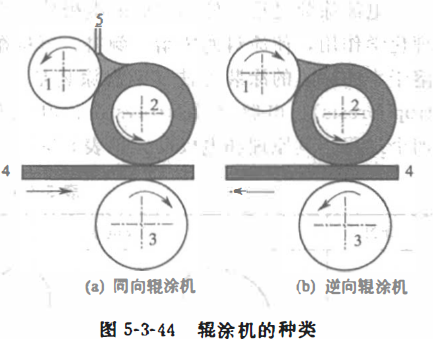

According to the similarities and differences of the rotation direction of the coating roller and the object to be coated, the roll coater can be divided into the same direction roll coater and the reverse roll coater, as shown in Figure 5-3-44. The rotating direction of the coating roller of the co-rotating roller coater is the same as the moving direction of the object to be coated. It is suitable for low-viscosity coatings, usually used for thin-film coatings, and the thickness of the coating film is generally 10~20µm . The rotation direction of the coating roller of the reverse roller coater is opposite to the moving direction of the object to be coated. It is suitable for thousands of high-viscosity coatings, and the viscosity can reach 120s (coating - 4 cups). Generally, a thousand-thickness film type coating is used, and the coating film thickness is generally 50 -500 μm.

Roller coating process

The material, combination, direction of rotation, gap between the rollers, peripheral speed ratio, and coating supply method of the roller coating machine are important factors affecting the quality of roller coating. Appropriate parameters should be selected according to specific roller coating requirements.

1. Control of film thickness

Generally, the larger the gap between the reclaiming roller and the coating roller, the thicker the film thickness of the roller coating, and the roller can be controlled by adjusting the peripheral speed ratio.

2. Selection of feeding method

There are two ways of feeding the roller coater: bottom feeding and top feeding. Bottom feeding is that the take-up roller picks up the coating from below, and the viscosity has a narrow application range, and its use is subject to certain restrictions. The top feeding is that the take-up roller takes the material from the upper part, the paint is easy to wet and adhere, and the application range is wide, and the application is relatively common.

3. Selection of coating roller

Coating rollers are generally rubber rollers, and steel coating rollers are used when the object to be coated is a flexible material, such as paper, cloth, and plastic film. During the coating process, the coating roller should be kept clean to prevent the adhesion of dust and foreign matter, and avoid damage to the coating roller, which will affect the appearance of the coating film.

4. Adjustment of peripheral speed ratio

The ratio of the rotation speed of the coating roller to the support roller is called the peripheral speed ratio. In order to apply the paint on the applicator roller to the surface of the object to be coated and obtain a satisfactory coating effect, it is necessary to select an appropriate peripheral speed ratio. When the reverse roller coating, the peripheral speed ratio should be slightly greater than 1; when the same direction roller coating, the peripheral speed ratio should be slightly smaller than 1, so that better coating effect can be obtained.