1. Definition

The softening point temperature mainly refers to the temperature at which the amorphous polymer begins to soften.

2. Measurement method

(1) Standard GB 8146-1987 Gum rosin and rosin test method.

(2) Principle Heating makes the sample fall from the ring under the action of steel ball gravity, and its temperature is the softening point.

(3) Operation Take about 5g of the resin crushed to a diameter of nearly 5mm in a drying dish, and slowly heat it to melt at the temperature possible to avoid bubbles and fumes. Immediately inject the molten resin into the preheated ring on the copper plate. After the resin is completely solidified, gently remove the copper plate. The ring should be filled with resin. If the resin in the ring has sunken or air bubbles, it should be remade. Place the prepared sample ring on the ring frame, install the steel ball locator on the circular plate, put the steel ball on the steel ball locator, and insert the thermometer from the top of the ring frame so that the bottom of the mercury is in contact with the ring frame. The bottom of is on the same level, and then put the whole ring into an 800mL beaker. After the above devices are completed, pour freshly boiled and cooled water below 35•c into the beaker, keeping 51mm from the top of the ring frame to the water surface. After standing for 10 minutes, heat it with an adjustable electric furnace or other heat sources to increase the water temperature by 5 °C per minute, and keep stirring fully to make the temperature rise evenly until the measurement is completed. When the resin wrapped with the steel ball falls to the flat plate, the temperature value read is the softening point of the resin. If the softening point of the sample is higher than so·c, the heat transfer fluid in the container should be changed to glycerin.

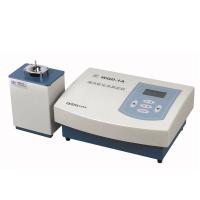

(4) Use an instrument softening point Tester, see Figure 2-7.